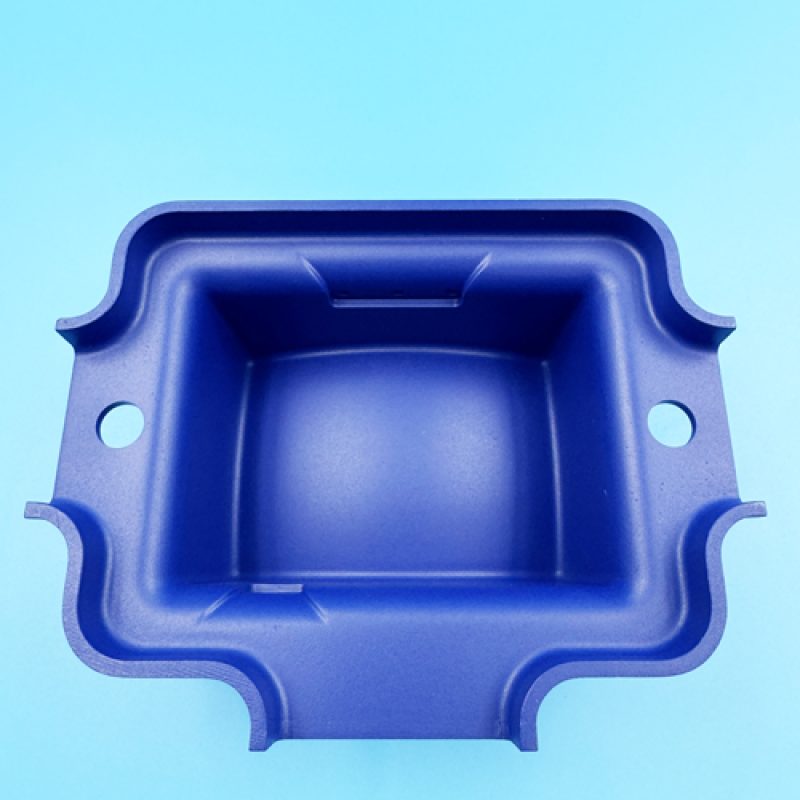

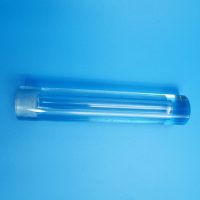

ABS vacuum casting parts are widely used in the consumer electronics industry. This is especially true for products that require high precision and complex appearance. ABS (acrylonitrile-butadiene-styrene) material has become an ideal material for electronic product housings and structural components. This is due to its excellent impact resistance and good surface finish. It helps to achieve a high-quality product experience. The vacuum casting process not only has excellent detail expression, but also can quickly replicate high-quality parts. Thus, it supports the small-batch production needs of products in the R&D and market verification stages.

Advantages of vacuum casting

Vacuum casting has great advantages in the field of consumer electronics. It can not only accurately replicate the details of the mold but also has good dimensional stability. This stability meets both the appearance and functional requirements of the product. After vacuum casting, ABS material shows excellent appearance and touch. It is suitable for various application scenarios such as smart devices, home appliances, and audio and video product housings. Moreover, through this process, design concepts can be quickly transformed into high-quality actual parts. This helps to accelerate product launch.

Why choose ABS vacuum casting parts?

- High-precision replication: The vacuum casting process can restore complex design details with high precision. It meets high standards of appearance requirements.

- Excellent mechanical properties: ABS material has the properties of impact resistance and anti-aging. It is suitable for consumer electronic products that require durability in daily use.

- Flexible customization: Supports diversified product designs, adapts to different appearance and structural requirements, and facilitates product differentiation.

- Cost-effective: Compared with traditional mold production, vacuum casting process is more cost-effective. It is suitable for small and medium batch customization needs.

We provide professional ABS vacuum casting parts solutions. These solutions achieve the best performance for the appearance and structure of consumer electronic products. We ensure production efficiency and quality, thus providing customers with competitive high-value products.

LKprototype

LKprototype