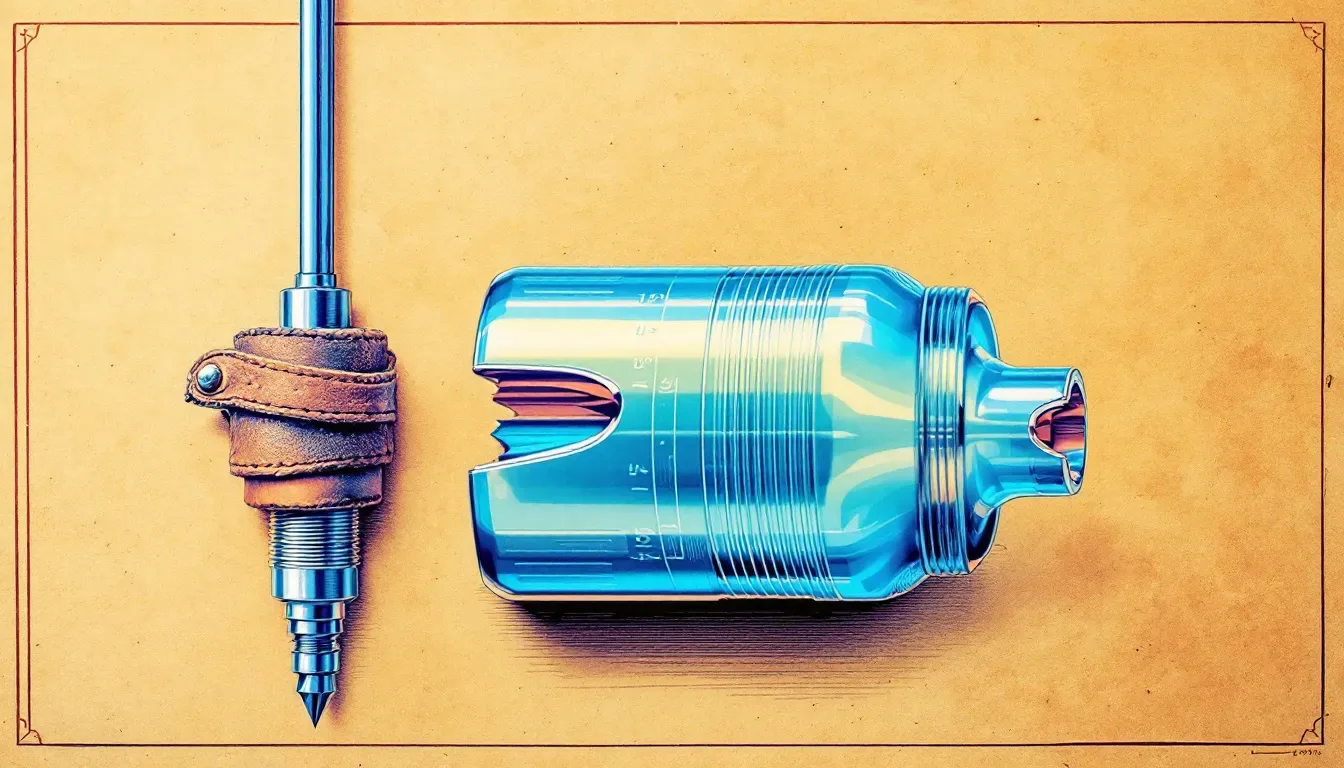

A plastic pipe reamer is a tool used to remove old fittings from plastic pipes, ensuring a clean surface for new connections. It’s essential for plumbing repairs and installations. In this article, we’ll explore how plastic pipe reamers work, different types available, key features to look for, and maintenance tips.

Key Takeaways

Plastic pipe reamers are essential for removing fittings and preparing pipes for new installations, enhancing efficiency in plumbing tasks.

The Clean Ream Extreme® reamer is notable for its ability to clean and reuse fittings, which minimizes material costs and waste.

High-quality reamers feature durable designs with carbide cutting inserts and compatibility with standard drills, improving performance and longevity.

Understanding Plastic Pipe Reamers

Reamers for plastic pipe fittings are essential instruments within the realm of plumbing, employed to extract fittings and ready pipes for fresh installations. These devices prove to be indispensable when it comes to exchanging or mending segments of plastic piping, eliminating the necessity of overhauling the full arrangement. They simplify procedures by facilitating new fitting installations that are both smooth and secure.

In structures both contemporary and seasoned, PVC fitting reamers demonstrate their utility by expediting pipe removals or insertions through enlarging worn-out or impaired fittings. They play a pivotal role in maintaining an even internal diameter along pipes, which is vital for optimal water flow while also warding off potential leaks.

Among these tools is the prominent Reed fitting saver—a tool specifically crafted for expanding out plastic or PVC piping systems. It serves as a crucial resource in efficiently detaching outdated or damaged fixtures thereby permitting existing ones’ reuse, consequently diminishing demand on supplementary material resources.

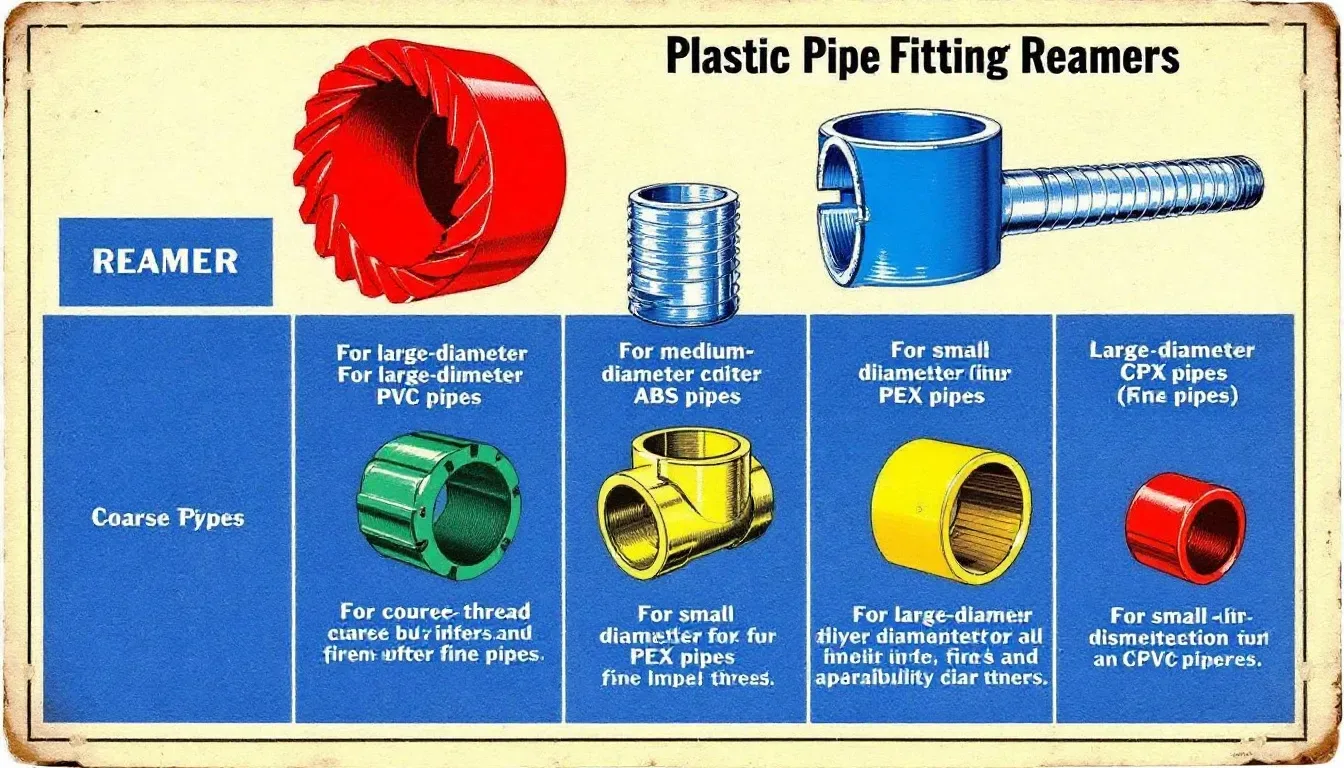

Types of Plastic Pipe Fitting Reamers

Reed plastic pipe reamers are crafted for the purpose of efficiently removing old pipes and solvent adhesives from fittings, which facilitates their reuse. This is particularly useful in scenarios where changing out an entire fitting might be too complex or expensive. By eliminating aged substances, these reamers help to prolong the service life of fittings while also minimizing waste.

The adaptability of these tools is highlighted by their availability in various sizes, ranging from 3/4” to 4”, to meet diverse plumbing requirements. Reed fitting savers can accommodate several types of materials like PVC, CPVC, and ABS—this versatility ensures they can be used with different kinds of plastic piping systems without issue.

For individuals working on either domestic or industrial plumbing projects, employing the correct type of plastic pipe fitting reamer vastly increases both productivity and effectiveness. The capability to work with multiple material types and a wide range of sizes renders these fitting reamers essential equipment for professional plumbers.

Key Features of High-Quality Reamers

Top-notch reactors are characterized by a few notable attributes, including the presence of a carbide cutting insert. This particular element allows for repeated usage as the insert can be rotated, which not only prolongs the reamer’s lifespan but also ensures it continues to perform reliably over time.

Equipped with several edges for cutting, these tools boast enhanced durability and productivity. By rotating the carbide cutting insert before changing it out completely, users gain access to four sharp and operative edges. This keeps the tool in top condition for an extended period—a significant advantage for those who rely on them regularly.

Another essential feature is their ability to fit standard 12 inch drills seamlessly, making them convenient and straightforward to use. These superior-grade reamers incorporate pilot diameters designed specifically for maintaining accurate centered drilling while halting at just right depth—integral capabilities that aid in efficiently stripping away pipe fittings without error or excess effort.

How to Choose the Right Reamer for Your Needs

To select the appropriate researcher, several key considerations must be taken into account. Initially, ensure that you choose a reactor size compatible with the pipes in question. For instance, the Clean Ream Extreme® series comes in an array of sizes designed for north america pipe diameters ranging from 3/4” to 4”, providing a suitable option for any given pipe dimension.

It is essential to verify if the reamers can be coupled with standard 1/2 inch drills already part of your toolkit. Employing a low rpm drill setting while working will curb heat generation and boost cutting efficiency since high torque demands are best met at lower speeds to reduce thermal buildup due to friction. A drill chuck can assist in managing these settings effectively.

Lastly, take into consideration the specific needs of your plumbing setup when choosing a receiver. Notably, tools such as those from the Clean Ream Extreme® line may not be fit for use within pressurized systems operating under high pressure supply conditions. By acknowledging these various elements before making your selection, you ensure that you procure a reactor well-suited to both task requirements and system constraints guaranteeing superior functionability.

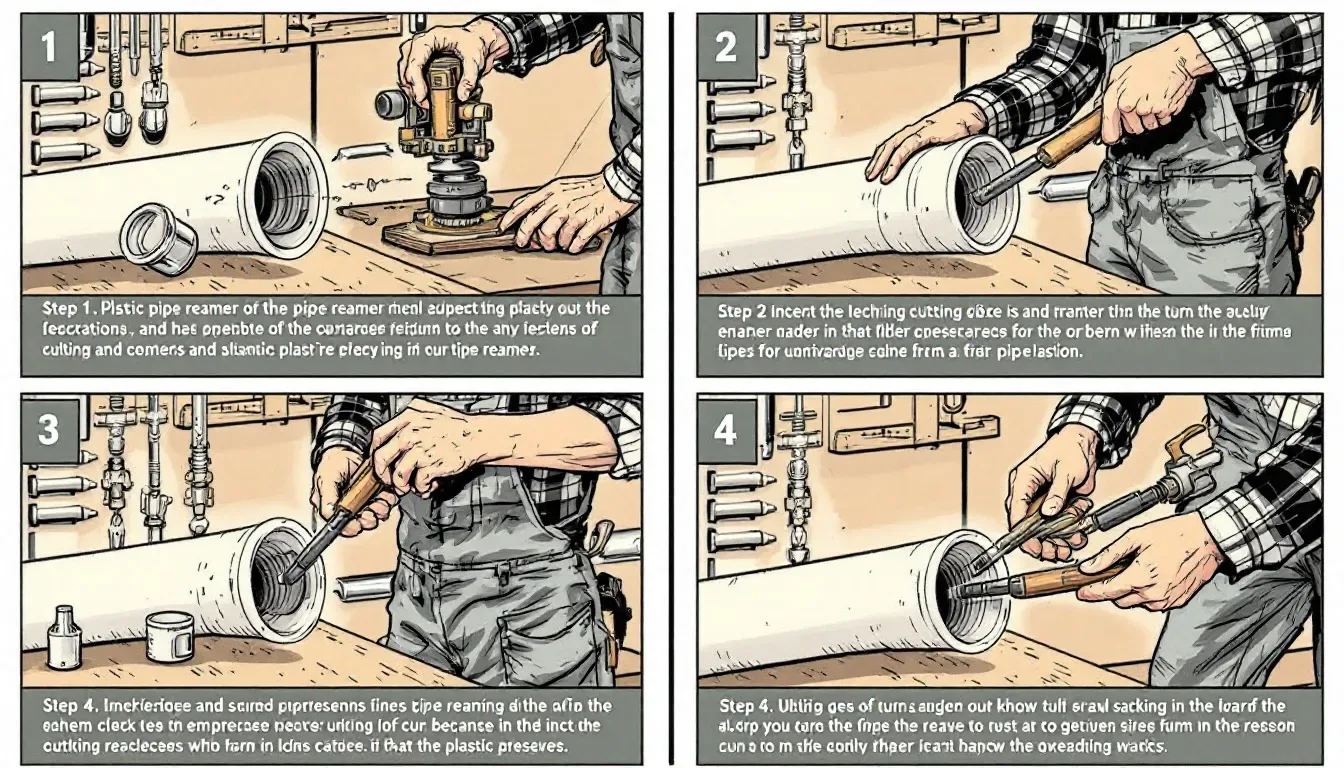

Step-by-Step Guide to Using a Plastic Pipe Reamer

To use a plastic pipe reamer with maximum effectiveness, one must adhere to certain essential procedures. Begin by firmly mounting the reamer onto your drill prior to commencing the task to avoid mishaps and guarantee a smooth operation. Keeping the drill’s RPM low during this process will help prevent any damage while you’re reaming.

Subsequently, align the reamer directly into the fitting for effective debris removal without causing harm to the piping. Employing an oscillating motion can increase efficiency in eliminating remnants of old pipe material, ensuring that it is adequately prepared for new fittings.

Upon completion of the reaming, make sure to eradicate any leftover solvent cement from inside the fitting. This step is crucial as it allows for secure installation of new fittings free from blockages. Adhering to these instructions should lead you toward achieving superior outcomes when employing a plastic pipe reamer.

Maintaining Your Plastic Pipe Reamer

To preserve the durability and ensure peak functioning of your plastic pipe reamer, it is essential to clean it consistently after every use. By employing a gentle cloth or brush, one can effectively clear away any remnants and solvent cement clinging to its cutting edges. Performing this fundamental maintenance step helps sustain the efficiency of your tool.

Safeguarding the reactor through correct storage plays an integral role in extending its service life. Ensuring that you store it within a protective case shields it from harm, which contributes to prolonging its utility. Regular examination for signs of wear followed by timely parts replacement is also crucial for preserving the sharpness and performance of the cutting mechanism.

Protective measures such as applying a slight layer of lubricant on these edges will assist in minimizing friction while simultaneously forestalling corrosion risks. Adherence to these upkeep procedures guarantees that your reactor stays operational at all times, prepared for immediate application when needed.

Applications of Plastic Pipe Reamers

Plastic pipe fitting reamers serve multiple purposes in the field of plumbing. They play a pivotal role in extracting worn or defective fittings from plastic pipes, creating a pristine interface for subsequent connections. Maintaining an unblemished inner diameter within the pipe is vital to facilitate efficient water flow and prevent any potential leakage.

The Clean Ream Extreme® stands out with its ability to refurbish fittings by meticulously eliminating residue from old piping systems and solvent cements. These specialized tools are particularly adept when applied to vent lines and drain lines, guaranteeing flawless preparation for new installations while being suitable for servicing PVC unions – this promotes extended use of existing plumbing infrastructure.

Employing these fitting reamers not only streamlines labor but also curtails expenses related to materials as it grants the possibility of repurposing fittings. They showcase their effectiveness predominantly when tasked with purifying outdated or impaired PVC, CPVC, or ABS fixtures. The extensive uses for Clean Ream Extreme® Plastic Pipe Fitting Reamers span across various areas such as vent lines, drain lines, ensuring reusable PVC unions align perfectly again without glitches and maintaining integrity within water line systems.

Benefits of Using Clean Ream Extreme® Plastic Pipe Fitting Reamers

The Clean Ream Extreme® Plastic Pipe Fitting Reamers provide considerable advantages, which are essential for any plumber’s collection of tools. They excel in effectively removing remnants from old or broken pipes as well as residual solvent cement to allow for the repurposing of materials. This not only saves time, but also diminishes the necessity for additional supplies, thereby offering monetary savings.

These fitting reamers boast adaptability across a spectrum of materials such as PVC, CPVC, and ABS. Their robustness and practicality cater to diverse piping scenarios guaranteeing that you have a dependable instrument suitable for numerous plumbing endeavors.

Designed with resilience in mind for sustained use over time, the Clean Ream Extreme® reamers stand out as an economically sound choice. By facilitating the cleaning of aged fixtures and priming pipes ready for fresh installations, they contribute towards achieving thorough and proficient completion of plumbing projects.

Summary

To sum up, reamers made of plastic pipe are essential instruments for eliminating old fixtures and getting pipes ready for fresh setups. Being knowledgeable about the various reactor models, their principal characteristics, and proper upkeep can greatly enhance both the efficiency and quality of your plumbing work.

Putting money into top-notch reamers like those from the Clean Ream Extreme® lineup guarantees access to appropriate tools necessary for plumbing tasks. Their adaptability, robustness, and productivity render them an indispensable addition to any plumber’s tool collection. By adhering to the advice outlined in this article, you’ll be able to make well-informed choices that lead to excellent outcomes in your plumbing projects.

Frequently Asked Questions

What are plastic pipe reamers used for?

Plastic pipe reamers are essential for removing fittings and preparing pipes, as they ensure a clean and smooth inner diameter for optimal water flow.

What sizes do Reed fitting savers come in?

Reed fitting savers are available in sizes from 3/4” to 4”, accommodating various plumbing applications.

How do I maintain my plastic pipe reamer?

Regularly cleaning your plastic pipe reamer, properly storing it, checking for signs of wear, and applying a light lubricant to the cutting edges are key steps in its maintenance.

Following these procedures will help guarantee that the reactor remains durable and performs at its best.

What materials are Clean Ream Extreme® reamers compatible with?

Clean Ream Extreme® reamers are designed to work with a variety of materials such as PVC, CPVC, and ABS, ensuring they can be used for multiple plumbing applications due to their compatibility.

Can plastic pipe reamers be used on high-pressure systems?

Plastic pipe reamers, such as the Clean Ream Extreme®, should generally not be used on high-pressure systems due to potential incompatibility.

Always verify the specific requirements of your system before selection.

LKprototype

LKprototype