Vacuum casting is the quickest and most cost-effective way to produce parts through low volume manufacturing in China. If you need high-quality parts for testing or launching new products, this method helps you save both time and money. With low volume manufacturing China services, you get your molds much faster than in other regions, typically within just 5 to 7 days.

Source | Average Lead Time |

|---|---|

Top 10 Vacuum Mold Casting Manufacturers in China | 5–10 working days |

Vacuum Casting/Silicone Molding/Urethane Casting Services | 7-12 Business Days |

Vacuum Casting for Rapid Prototyping | 7 to 15 days |

You don’t have to invest in expensive tooling. With low volume manufacturing China, you only pay for what you need. This approach allows you to gather customer feedback before committing to large-scale production. It helps you improve your products, reduce risk, and refine designs before ramping up manufacturing.

Key Takeaways

Vacuum casting is a quick and cheap way to make good parts. You can test your designs before making many parts.

China has a strong supply chain and good factories. This helps you get parts fast, sometimes in 5 to 7 days.

Vacuum casting means you do not need pricey tools. You only pay for what you use. You can get feedback from customers early.

Bridge production, like vacuum casting, helps you move from samples to big orders. This lowers risks and saves money.

People check the quality often in vacuum casting. This makes sure the parts are always good. You can give your customers products they can trust.

Why Pick China for Low Volume Manufacturing? ⭐⭐⭐

China is a great place to make small batches of products. There are many factories and suppliers in China. This helps you go from an idea to finished parts fast. China’s manufacturing system can make many types of products. These include electronics and things people use every day.

Here is a table that shows why China is a leader in low volume manufacturing:

Factor | Description |

|---|---|

Massive Scale and Ecosystem | Handles large volumes and many product types. |

Advanced Infrastructure | Ports, roads, and factories boost production speed and efficiency. |

Skilled Workforce | Workers have strong experience in many manufacturing processes. |

Technological Advancements | Uses AI, robotics, and smart tools in factories. |

China has a strong supply chain. Many suppliers and factories work close together. This makes it easy to find the right partner for your project. You can pick from many materials and ways to make things. If you want to change your design, you can do it fast.

China’s supply chain is strong and can change quickly.

Good roads and shipping help move goods fast in China and to other countries.

You can choose the best place to make your products. This helps you meet what the market wants.

Many factories use new technology, so you get good quality parts.

China’s factories can start making things very quickly. They have a lot of experience with low volume manufacturing china. This means you get results you can trust. You can test your product before spending a lot of money. This way, you take less risk and make smarter choices.

Tip: If you work with Chinese factories, you can start selling sooner. You can also make your product better by listening to real feedback.

What Is Low Volume Manufacturing?

Definition and Typical Production Volumes

Low volume manufacturing means making only a small number of products. You can make just a few items or up to a few thousand. This method is good for prototypes or custom products. It helps you test new ideas before making lots of them. Car companies use low volume manufacturing for special cars. These cars have custom features for each buyer. Electronics brands use it for limited-edition gadgets. They also use it to test new devices with a small group. Low volume manufacturing china services help you get products fast. It also costs less than making huge amounts.

Challenges When Scaling from Prototype to Mass Production

It is hard to go from a prototype to many products. You will face many problems when you do this. Here are some common issues:

Design limits may stop you from using the same materials. You might need to change your design.

Checking quality gets harder with more products. You must look at every part to make sure it is good.

Supply chain problems can slow you down. Getting enough materials on time is not always easy.

Costs can go up quickly. You need to keep prices low but still make good products.

What people want can change. You must listen to feedback and change your product.

To lower these risks, work closely with your partners. They can help you design things that are easy to make. They can also help you find good suppliers. Check for problems before they happen. Set up strong checks for quality. Many companies use low volume manufacturing china to test products and supply chains. This helps them fix problems early. Then they are ready for bigger orders.

Tip: Always be ready for changes. The market can change fast, so keep improving your product.

What Is Bridge Production and Why It Matters ⭐⭐⭐

The Role of Bridge Manufacturing

You need a safe way to go from making a few samples to making lots of products. Bridge production helps you do this. People also call it bridge tooling or pilot production. It uses special ways to connect early design with big production. In bridge production, you use rapid prototyping and short-run tools. This lets you test your product in real life before making thousands.

Bridge production gives you many benefits:

You can make small batches fast.

You can meet what the market wants right away.

You can start selling early and get feedback quickly.

Bridge production helps you launch your product sooner. You can be first in the market. In China, factories are skilled and have good technology for bridge production. You can use bridge production to test your design and check quality. You can also make changes before spending a lot of money on mass production. Bridge production can help you get money from investors. They like to see real products tested in the market.

Bridge production uses tools like 3D printing and vacuum casting. You can change your design and test again if you need to. This process helps you feel sure before making a lot of products. Bridge production makes your time-to-market shorter. It helps you stay ahead of other companies.

Risks of Jumping Directly to Injection Molding

If you skip bridge production and go straight to injection molding, you can have many problems. Look at the table below to see what might happen:

Risk Type | Description |

|---|---|

Design Errors | Errors in the design phase can lead to defects in the final product. |

Production Scaling Risks | Without a prototype, scaling production can result in unforeseen challenges and inefficiencies. |

Cost Increases | Mistakes made without prototyping can lead to higher costs in fixing issues later on. |

Quality Assurance Issues | Prototyping helps ensure the final product meets quality standards, reducing defects. |

Customer Satisfaction Concerns | Skipping prototyping can lead to a product that does not meet customer expectations. |

Bridge production helps you avoid these problems. You can fix design mistakes, keep costs low, and make sure your customers are happy. Bridge production gives you a safe way to go from an idea to making lots of products.

Vacuum Casting as the Ideal Bridge Manufacturing Process ⭐⭐⭐

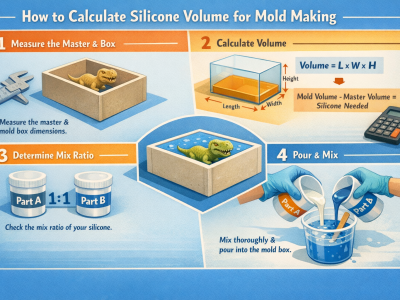

How Vacuum Casting Works

Vacuum casting helps you make good parts fast. First, you design a master model using CAD software. You can make this model with CNC machining or 3d printing. Then, you put the master pattern in a box. You pour liquid silicone around it. The silicone forms a mold and copies every detail. After the mold dries, you mix casting resins. You pour the resin into the mold using vacuum pressure. The vacuum takes out air bubbles. It also helps the resin fill the mold. When the resin gets hard, you take out the finished part. This way, you get parts that are exact and have no mistakes.

Tip: Vacuum casting is good for checking your design and testing how it works before making lots of products.

Materials and Applications

Vacuum casting works with many materials. You can pick polymers, metals, alloys, or composites. Each material has its own special use. For example, ABS-like resins are strong and last a long time. PC-like resins are clear like glass. Polyurethane resins can act like ABS or polypropylene plastics. Silicone rubbers and other special materials are used for soft or bendy parts.

Material Type | Description |

|---|---|

Polymers | Plastics, rubbers, and elastomers for strong and flexible parts. |

Metals | Soft and conductive materials for special uses. |

Alloys | Mixed metals for better qualities. |

Composites | Combined materials like fiberglass and carbon fiber. |

Vacuum casting is used in cars and electronics. Car makers use it for dashboards and custom parts. It is also used for electric vehicles. Electronics companies use it for small and detailed parts. Many industries use vacuum casting to make special products.

Comparison to CNC Machining and 3D Printing

Vacuum casting is best for making a small number of parts. You spend less money on tools and get parts faster than with CNC machining. CNC machining is more exact but costs more for small batches. 3d printing is quick for making samples and custom parts. But the surface and details are not as good as vacuum casting. The table below shows how these ways are different:

Manufacturing Method | Cost for Low Volume | Speed | Quality |

|---|---|---|---|

Vacuum Casting | Most cost-effective for 5-100 parts | Moderate | Comparable to CNC in surface finish, less precision |

CNC Machining | More cost-effective as volume increases | Slower for low volume | Higher precision, excellent surface finish |

3D Printing | More expensive per part for low volumes | Fast for prototyping | Good for customization, but lower precision than CNC |

Vacuum casting gives you a good mix of speed, price, and quality for small batches.

Advantages of Vacuum Casting for Low Volume Manufacturing in China

Cost and Lead Time Advantages

Vacuum casting helps you get parts fast and save money. You do not need to buy costly metal tools. Silicone molds copy every detail of your design. You get good parts without extra work. In low volume manufacturing china, making molds takes only 1 to 3 days. After that, you get finished parts in just 24 hours. This quick process lets you test ideas and get feedback soon. For batches of 10 to 500 units, vacuum casting keeps costs low. It makes small production possible for many companies.

Design Flexibility and Rapid Iteration

You can change your design and see results quickly with vacuum casting. This method lets you pick from many materials and surface looks. You can test different versions or colors without waiting long. When the silicone mold is ready, you can make many parts in a few days. This helps you move from testing to full production easily. Vacuum casting works well with additive manufacturing. You can use 3D-printed master models to speed up your work.

Tip: Try vacuum casting to improve your design before mass production. You can make changes and test new ideas with little risk.

Quality Consistency and Risk Reduction

Vacuum casting uses strict checks to make sure every part is good. The process needs careful vacuum pressure and exact mold alignment. Regular checks and care keep molds working well. Factories in low volume manufacturing china watch each step closely. They check parts by looking and finishing them. The table below shows important quality control steps:

Quality Control Measure | Description |

|---|---|

Vacuum Pressure | Calibration makes sure parts fit and have no defects. |

Mold Alignment | Correct alignment keeps sizes the same. |

Mold Design and Maintenance | Good design and care stop wear and keep parts precise. |

Process Monitoring | Checks during work catch problems early and show patterns. |

Post-Forming Inspection | Final checks make sure only good parts are sent to you. |

You lower risk by finding problems early and making sure each part matches your design. This way, you give your customers products they can trust.

Trade-Offs and Limitations of Vacuum Casting

When Vacuum Casting Is Not Suitable

Vacuum casting gives you many benefits, but it does not fit every project. You should know when this process may not work for your needs.

Thermal stress can cause problems. If the temperature changes too fast, your parts may warp or crack.

You may see inconsistent microstructure. This means the inside of your part might not be the same everywhere, which can affect how it works.

Mold and die wear happens often. High heat and vacuum conditions can damage the molds, so you may need to replace them more often.

You need extreme process control. Keeping the vacuum and temperature just right takes skill and special machines.

Large parts are hard to make. Vacuum casting works best for small, high-value items. If you need big parts, you may want to look at other methods.

Note: If you need to make very large parts or want to produce thousands at a time, you should consider other manufacturing options like injection molding or additive manufacturing.

Material, Size, and Volume Constraints

Material choice matters a lot in vacuum casting. You must think about how flexible, strong, or heat-resistant your material needs to be. If you use a flexible material, check if your design can handle bending without breaking. If you use a rigid material, avoid sharp corners that could crack.

You also need to follow some rules for part design:

Keep wall thickness consistent. If the walls change thickness, your part may cool unevenly and get weak spots.

Try to keep wall thickness between 0.75 mm and 1.5 mm for small to medium parts. Bigger parts need thicker walls.

Remember that vacuum casting is best for small batches. It works well for prototypes and limited runs, but not for mass production.

Vacuum casting lets you make small numbers of parts quickly and at a lower cost. This makes it a smart choice for testing ideas or making custom products before you move to larger-scale production.

Supporting Product Improvement Before Mass Production

Design Validation and Functional Testing

You want to make sure your product works before you make thousands of them. Vacuum casting helps you do this. You can create high-fidelity prototypes that look and feel like the final product. These prototypes let you check fit, form, and function. You can see if parts fit together. You can test how strong or flexible they are. You can also check if the product looks good.

Vacuum casting gives you parts with fine surface detail and good accuracy. You can spot design problems early. You can fix these problems before you spend a lot of money. The process uses silicone molds and special resins. These materials copy even small details and complex shapes. You get a clear idea of how your product will look and work.

Here are some ways vacuum casting helps you improve your design:

You can test how parts fit together.

You can check if the product works as planned.

You can see and feel the surface finish.

You can find and fix design issues early.

Tip: Use vacuum casting to get feedback from your team or customers before you move to mass production.

Preparing for Injection Molding Transition

Vacuum casting also helps you get ready for injection molding. You can use the prototypes to test your design in real situations. You can make changes if you find problems. This step makes the move to mass production smoother.

You can try different materials and colors. You can see which one works best. You can also check if your design is easy to make with injection molding. If you need to change the shape or size, you can do it now. This saves you time and money later.

Vacuum casting supports your product development process. You can make better choices and reduce risk. You feel more confident when you start mass production.

FAQ – Low Volume Manufacturing in China

1. What is low volume manufacturing?

You use low volume manufacturing to make a small number of parts. This method helps you test your design before you start mass production. You can make changes quickly and save money.

2. How fast can I get my parts in China?

Factories in China work quickly. You can get your first parts in as little as one week. The time depends on your design and the number of parts you need.

3. What materials can I use?

You can choose from many materials. These include plastics, rubbers, and some metals. Ask your supplier for a list of options.

4. Is low volume manufacturing expensive?

You pay less for low-volume production than for mass production. You do not need to buy expensive tools. You only pay for the parts you need.

5. Can I change my design after I start?

Yes, you can change your design. Factories in China can make new molds or adjust your order. This helps you improve your product before you make many parts.

Tip: Always talk with your supplier about changes. Good communication helps you avoid mistakes.

6. How do I know if my parts are good quality?

You can ask for samples before you order more. Many factories offer quality checks and reports. You can also visit the factory or hire a third party to check the parts.

7. What is the best way to ship my parts?

You can use air or sea shipping. Air is faster but costs more. Sea shipping takes longer but saves money. Your supplier can help you choose.

Shipping Method | Speed | Cost |

|---|---|---|

Air | Fast | Higher |

Sea | Slower | Lower |

8. Why should I choose China for low volume manufacturing?

You get fast service, many material choices, and skilled workers. China has a strong supply chain. You can move from idea to finished part quickly.

Conclusion – From Low Volume to Mass Production with Confidence

You want to make your ideas real. Vacuum casting helps you go from making a few parts to making many. You can test your design first. You get feedback and make your product better. This way, you save money and avoid mistakes.

Here are the benefits of vacuum casting in China:

You get your parts fast.

You spend less on small batches.

Your parts look and feel like the final ones.

You can change your design quickly.

Tip: Try vacuum casting to check how your product fits, works, and looks. You can fix problems early and lower your risk.

Chinese factories help you develop your product. They have skilled workers and good machines. Their supply chains are strong. You can pick from many materials and finishes. Experts help you solve problems.

Step | What You Achieve |

|---|---|

Design and Test | Find and fix design issues |

Small Batch Runs | Get real feedback from users |

Improve and Iterate | Make changes before scaling up |

Mass Production | Launch with confidence |

You can go from an idea to a finished product with less worry. Vacuum casting is your bridge. You can enter the market faster and make smart choices for your business.

If you want to know more or start a project, talk to a trusted low volume manufacturing partner in China. Take action and turn your idea into something real.

Vacuum casting gives you a fast and affordable way to make real parts before you scale up. You can test your ideas, improve your design, and lower your risk. This process helps you move smoothly toward mass production. Think about vacuum casting as your next step. If you want to learn more, reach out to a trusted partner in China. You can start your project with confidence.

LKprototype

LKprototype