When learning how to design for prototyping in China factory settings, it’s important to start with a clear plan. First, define your product’s goals and sketch out your ideas. Next, create digital models to visualize your concepts more effectively. As you move forward with how to design for prototyping in China factory environments, use rapid methods like CNC machining or 3D printing to build physical prototypes and test your design. Protect your intellectual property with patents or NDAs. Prepare detailed drawings and a bill of materials. Choose materials and manufacturing processes that align with your plan. For the best results in how to design for prototyping in China factory projects, develop a solid strategy and select a reliable China prototyping company. Collaborate closely with the company, provide feedback, and refine your design. Keeping thorough records and maintaining open communication will help your strategy succeed.

Key Takeaways

Begin your prototyping project with clear goals. Make detailed drawings and a full bill of materials. This helps you avoid mistakes and delays.

Use rapid prototyping methods like 3D printing and CNC machining in China. These methods save time and money. They help you test and improve your design fast.

Protect your ideas by registering patents early. Use strong NDAs. Work with trusted Chinese partners who respect your intellectual property.

Pick the right materials and manufacturing processes for your design needs. Make sure they fit your budget. This helps you get good quality and cost balance.

Talk clearly and often with your China prototyping company. Use simple English and visuals. Build good relationships to make teamwork smooth and get better results.

Prototyping in China

Prototype Types

When you begin prototyping in China, you have many choices. Chinese factories offer lots of rapid prototyping services. These services help you make a product prototype fast and test your ideas. You can pick from different prototype types like visual models, functional prototypes, or engineering samples. Each type has its own job in the rapid prototyping process.

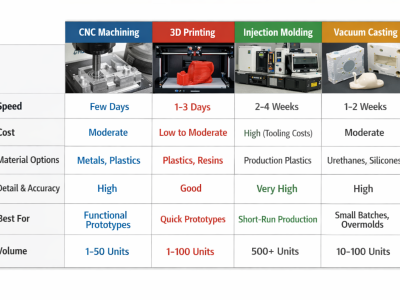

Here is a table that lists the most common prototyping services you can use in China:

Prototyping Service | Description / Usage Frequency |

|---|---|

Rapid Prototyping | Many companies offer this, like Superior Prototype, Starrapid, RP Group, Soma Prototype, and others. |

This is common at firms such as GS Proto, WayKen, A-One Group, and RapidDone. | |

3D Printing | Many companies offer this, like Lexcent, Prototech Asia, and HLH Prototypes. |

Injection Molding | Used for plastic parts by LK-Mould, Mold Making, and KG Model. |

Companies like GS Proto, Starrapid, and 3ERP offer this service. | |

Sheet Metal Fabrication | RP Group, Superior Prototype, and Soma Prototype provide this service. |

Silicone Molding | GS Proto and Lexcent offer this service. |

Die Casting | GS Proto, KG Model, and TeamRAPID provide this service. |

Rapid Tooling | Starrapid, 3ERP, and TeamRAPID offer this service. |

Low Volume Production | Superior Prototype, RP Group, and KG Model provide this service. |

Finishing Services | Starrapid, GS Proto, and 3ERP often include these as extra services. |

Design Support Services | Some companies like WayKen, Agilian Technology, and Able Industrial Design offer this, but it is less common. |

You can use these rapid prototyping services to make a product prototype at any step of your project.

Rapid Prototyping in China

Rapid prototyping in China is important when you need to work fast. Many companies pick rapid prototyping in China because it saves time and money. The rapid prototyping process uses tools like 3D printing, CNC machining, and injection molding. These methods let you make a product prototype quickly and test it right away.

Rapid prototyping in China helps you get your product prototype to market faster.

You do not need expensive tooling and can use digital designs for rapid prototyping.

The rapid prototyping process in China costs less than old methods.

Many companies in the automotive and medical fields use rapid prototyping in China for good results and lower costs.

You should use rapid prototyping in China if you want to test ideas, improve your design, and launch your product prototype fast. Rapid prototyping is important because it is quick, flexible, and saves money. You can repeat the rapid prototyping process as many times as you need to get the best product prototype.

Tip: Always tell your rapid prototyping partner in China what you need. This helps you avoid mistakes and get the best results from the rapid prototyping process.

Design Files

Technical Drawings

You must make technical drawings before sending your design to a Chinese factory. These drawings show all the details of your product. Most Chinese prototyping factories use STEP and IGS files for 3D models. If you want SLS 3D printing, send STL files. For CNC machining, IGS files are best. Always ask your supplier which file format they need.

Your 2D drawings should have important information. Add a title block with your company name, designer, part number, and revision date. Show your product from many angles. Use sectional views to show hidden parts. Mark every dimension and set clear tolerances. Write notes about surface finish, color, and special treatments. If your part has features that matter for quality, use geometric tolerancing to highlight them.

Tip: Check your drawings for missing details. Clear drawings help the factory avoid mistakes.

Bill of Materials

A Bill of Materials (BOM) lists every part and material in your product. You should make a BOM that is easy to read and complete. List each item with its part number, name, material, quantity, and supplier. If you use special materials or finishes, write them in the BOM. This helps the factory order the right parts and keep track of costs.

Part Number | Name | Material | Quantity | Supplier |

|---|---|---|---|---|

001 | Top Cover | ABS | 1 | ABC Plastics |

002 | PCB Board | FR4 | 1 | XYZ Circuits |

003 | Button | Silicone | 2 | DEF Rubber |

Documentation Tips

Clear and detailed documentation helps your project go well. When you write your quality standards and design goals, everyone knows what you want. This lowers mistakes and helps the factory check quality at every step. Good documentation also makes it easier to fix problems and improve your design.

Research shows that clear and updated documents help teams work better. You can share knowledge, fix mistakes faster, and keep your project on track. Always update your files if you make changes. This way, everyone knows what is happening and can get ready for the next step.

How to Design for Prototyping in China Factory

Sketches and Virtual Models

You begin by drawing your ideas on paper. Quick sketches help you show your first thoughts. These drawings let you explain your idea to your team and the Chinese factory. You do not need to draw perfectly. Simple shapes are enough for early planning.

After sketching, you use digital tools. Digital models help you plan your product prototype better. You can make 2D or 3D models with software. These models show what your product will look like and how it works. They also help you check if your design follows rules and is safe.

Here are some tips for making sketches and digital models for rapid prototyping in China:

Start with hand sketches to get ideas down fast.

Make digital 2D or 3D models for planning and sharing.

Ask professional designers for help if needed.

Talk to your Chinese manufacturer early to fit their process.

Stay in contact with your supplier to avoid mistakes.

Protect your ideas by writing IP rights in your contracts.

Try rapid prototyping methods like 3D printing to test your prototype.

Make important design choices early to save money and time.

Build good relationships with your manufacturer for better results.

Watch for language and culture differences so everyone understands.

You can use many digital modeling tools with Chinese prototyping companies. Here is a table of popular software:

Software | Description | Relevance to Chinese Prototyping Companies |

|---|---|---|

Sketch | Digital design platform for Mac; supports prototyping and interactive designs. | Favored by designers for prototyping and design workflows. |

Anima | Design-to-code tool; integrates with Sketch, Figma, Adobe XD. | Enables high-fidelity prototypes and smooth handoff to developers. |

InVision | Interactive prototyping with collaboration features. | Popular for team communication and prototyping. |

Uizard | AI-powered rapid UI design and prototyping tool. | Used for fast prototyping and collaboration. |

Penpot | Open-source design and prototyping platform. | Free tool for design systems and code inspection. |

Marvel | Wireframing and prototyping tool for teams. | Used for scalable design and prototyping. |

Pencil Project | Open-source UI drafting tool. | Useful for early-stage prototyping. |

Origami Studio | Advanced prototyping with hardware API integration. | Supports complex prototypes and hardware interaction. |

When you use these tools, it is easier for your Chinese partners to follow your plan and make good prototypes.

Tip: Share your digital models with your manufacturer early. This helps you find problems before making a real prototype.

Physical Prototypes

After finishing your digital models, you make a physical prototype. This step is very important in how to design for prototyping in China factory. You use rapid prototyping methods like 3D printing, CNC machining, or injection molding. These methods help you turn your digital design into a real product prototype.

Chinese factories can make simple prototypes in about three days. If you live in the US, you usually get your prototype in 9 to 13 days, including shipping. The cost of rapid prototyping in China is 20-40% less than in the US. Labor is cheaper, and materials like ABS plastic cost less. You save money and get your product prototype faster.

You need to plan each step. Pick the right rapid prototyping method for your needs. 3D printing is good for quick, cheap models. CNC machining makes strong and exact parts. Injection molding is best for testing how your product prototype looks and feels.

Testing is very important now. You check if your prototype matches your plan. You look for problems and fix them. You may need to make new prototypes a few times. Each new prototype helps you get closer to a final product that works well.

Note: Always test your prototype for function, fit, and safety. Use feedback from your team and Chinese partners to make your design better.

IP Protection (Patents, NDAs)

Protecting your ideas is a big part of how to design for prototyping in China factory. You want to keep your product prototype safe from copycats. China uses a first-to-file system for patents. This means you should register your IP rights with the China National Intellectual Property Administration (CNIPA) as soon as possible.

Here are steps you can take to protect your intellectual property during rapid prototyping in China:

Register your patents, trademarks, and copyrights with CNIPA early.

Work with local IP experts who know Chinese law.

Check your manufacturing partners carefully. Visit their factories if you can.

Use strong contracts, including Non-Disclosure Agreements (NDAs) and non-compete clauses, that are enforceable in China.

Use secure data management and digital watermarking to track your files.

Keep a local presence or hire trusted third-party inspectors to watch over your project.

Respond quickly if you see any IP problems. Gather evidence and talk to local legal experts.

Update your IP registrations and contracts as your plan changes.

You should also focus on your most valuable inventions and trademarks. Only share what is needed with your manufacturing partners. Sometimes, you can keep the most sensitive parts of your product prototype outside China to lower risk.

Alert: Never skip IP protection. Register your rights, use NDAs, and choose partners with a good reputation. This keeps your plan and your product prototype safe.

Materials & Processes

Material Selection

You must pick the right materials for rapid prototyping in China. Chinese factories have many choices for rapid prototyping. Plastics like ABS, PLA, PC, PMMA, and Nylon are used a lot. These plastics are strong, easy to shape, and not expensive. Metals such as aluminum alloy, stainless steel, copper alloy, and titanium alloy are good for strong and tough prototypes. Composites like Glass Fiber Reinforced Plastic (GFRP) and Carbon Fiber Reinforced Plastic (CFRP) are light but very strong.

Material Category | Common Materials | Key Properties | Typical Applications |

|---|---|---|---|

Plastics | ABS, PLA, PC, PMMA, Nylon | Strength, impact resistance, transparency, biodegradability | Functional and visual prototypes |

Metals | Aluminum alloy, Stainless steel, Copper alloy, Titanium alloy | Strength, corrosion resistance, machinability | Functional prototypes, electronics |

Composites | GFRP, CFRP | High strength-to-weight ratio, fatigue resistance | Aerospace, automotive, sports goods |

You should choose materials that work with your rapid prototyping method. Plastics are used most because they are cheap and easy to use. Metals and composites are better for strong or special prototypes.

Manufacturing Processes

Chinese factories use different ways to make rapid prototypes. 3D printing is good for making tricky shapes fast. CNC machining makes parts that are smooth and exact. Injection molding is best if you need many copies quickly and for less money. Other ways include vacuum casting and sheet metal fabrication. These methods help you get your prototype fast and try out your ideas.

3D printing: Good for fast, detailed, and tricky prototypes.

CNC machining: Makes strong, exact, and quick prototypes.

Injection molding: Great for making many cheap prototypes fast.

Vacuum casting: Works well for small batches and flexible prototypes.

Tip: Ask your factory which process matches your design and budget.

Cost, Speed, and Quality

The material you pick changes the price and quality of rapid prototyping in China. Plastics like ABS are cheap and last a long time. Metals like aluminum alloy cost more but make strong prototypes. Hard metals like stainless steel and titanium cost even more because they are hard to cut. If a material is tough, it takes longer to make and wears out tools faster.

Chinese factories finish rapid prototyping jobs quickly. Many companies can make simple prototypes in one or two days. Most projects in China are done in three to seven days. You get good prototypes for less money because of new technology and strong factory teams. This makes rapid prototyping in China a smart way to save money.

Note: Always think about cost, speed, and quality to get the best results.

DFM (Design for Manufacturability)

DFM Principles

When you design for manufacturing in China, you need a good plan. Rapid prototyping in China works best if you follow some important DFM principles. These rules help you avoid mistakes and save money. Here are the main ideas for your plan:

Simplification: Try to use fewer parts and steps. This makes your product prototype easier and cheaper to make.

Standardization: Use parts that are easy to find in China. This helps lower costs and keeps quality high.

Material Selection: Pick materials that work well with rapid prototyping and fit your needs.

Early Integration: Start using DFM ideas at the very beginning.

Design Reviews and Iterations: Work with your team and Chinese partners to check and improve your design.

Prototyping and Testing: Use rapid prototyping in China to test your product prototype and make sure it works well.

Managing Tolerances: Set tolerances that balance cost and how your product prototype works.

Material Availability: Choose materials that are easy to get in China so you do not have delays.

Compliance with Standards: Make sure your product prototype meets safety and quality rules.

Collaboration with Manufacturing Engineers: Talk to experts early so your design matches rapid prototyping in China.

Utilizing DFM Software Tools: Use software to find risks and make your rapid prototyping plan better.

Continuous Improvement: Keep making your plan better to improve quality and speed.

Tip: If you work with your Chinese factory early, you can find problems before they cost you money.

Prototype vs. Production

You use rapid prototyping in China to check your design and fix problems early. At this stage, your plan is about testing your product prototype with fast methods like 3D printing or CNC machining. You want to see if your idea works, so you test for fit, function, and safety. Rapid prototyping lets you make changes quickly and try new ideas.

When you move to mass production, your plan changes. Now, you want to make lots of product prototypes fast and for less money. You use processes like injection molding for big batches. Your plan should focus on easy assembly, checking quality, and managing the supply chain. Rapid prototyping in China helps you get ready for this step by finding and fixing design problems early.

Note: Rapid prototyping in China is for testing and learning. Mass production is about making things fast, cheap, and with good quality.

Common Adjustments

When you go from rapid prototyping to mass production in China, you often need to change your plan. Here are some common changes:

Use fewer parts to make assembly faster and cheaper.

Make your design strong and good for making many at once.

Use pre-production prototypes that are the same as the final product prototype in material and size.

Visit factories to check their rapid prototyping and production skills.

Finish your design with last changes found during rapid prototyping.

Set up strong quality checks to lower mistakes.

Pick the right factory by using a careful RFQ process.

A good plan means you use rapid prototyping in China to test, learn, and get better. Then you change your plan for mass production to save time and money.

Callout: Always use rapid prototyping in China to find problems early. Change your plan before mass production for the best results.

Choosing a China Prototyping Company

Research & Shortlisting

When you want to find a china prototyping company, you need to plan. First, make a list of companies that fit your project. Check if they have experience with rapid prototyping and can make good prototypes. See if they use new machines like 3D printers and CNC machines. Look for finishing tools too. Certifications like ISO 9001 or ISO 13485 mean they care about quality.

Here is a table to help you compare suppliers:

Criteria | What to Look For |

|---|---|

Experience | Years in rapid prototyping, proven track record |

Technology | Modern machines, up-to-date rapid prototyping tools |

Cost Transparency | Clear pricing, no hidden fees |

Communication | English-speaking staff, fast replies |

Quality Assurance | Regular checks, strong quality systems |

IP Protection | NDAs, legal agreements |

Project Handling | Can manage complex projects and tight timelines |

Customization | Willing to adapt to your design needs |

You should always check reviews from other clients. If you can, visit the factory to see how they work. Use safe payment methods like PayPal or bank transfer for extra safety.

Communication & Quality

Talking well with your china prototyping company is very important. You need to trust your supplier. Learn about their culture and show respect. Always talk to the most senior person in meetings. Use simple English or a language you both know. If you can, visit their factory. This lets you see their rapid prototyping process and how they check quality.

Quality is important for every prototype company. The best companies check parts during and after making them. Some use outside inspectors for more safety. Ask your supplier for reports about problems and how they fix them. Good suppliers have plans for issues and can use backup suppliers if needed.

Tip: Keep talking with your supplier. Give feedback early. This helps them make better prototypes for you.

IP & Risk Management

Keeping your ideas safe is very important when working with a china prototyping company. You must use written contracts that say you own all IP rights. Ask your supplier to sign NDAs and non-compete agreements. This keeps your designs safe from copycats.

Work with Chinese legal experts to check your contracts. Make sure the supplier’s staff signs IP transfer agreements too. Always check the company’s background before you choose them. You can set up audits to watch for leaks. Only let a few people see your most secret designs. If you need to end the deal, your contract should let you leave and keep your rights.

Alert: Never skip legal steps. Strong contracts and checking the supplier protect your ideas and your business.

Manufacture a Product in China

Transition from Prototype to Production

When you want to manufacture a product in China, you must move from making a prototype to making many products. First, check if your prototype works well and meets your design needs. Work with your supplier to plan the best way to make your product. Here are some steps you should follow:

Make sure your supplier agrees your prototype is ready.

Plan how to make your product, including tools and parts.

Do a small test run before making lots of products to find problems.

Check if your supplier’s quality control is good.

Watch your supply chain so you always have the right materials.

Use feedback and new technology to keep getting better.

There are two main ways to manufacture a product in China. In the Western way, you control the design and pay for tools and parts. This gives you more control but costs more money. In the Chinese way, your supplier does most of the work. This is faster but you have less control. Always plan with your supplier and check the quality often.

Tip: Always do a test run before making lots of products. This helps you find problems early and saves money.

Certifications & Compliance

You need certifications when you manufacture a product in China. You must follow Chinese and international rules. The CCC mark is the most common certification. You need this mark for many things like electronics and car parts. Your supplier should help you get this mark by passing safety tests and factory checks.

Other things you should do are:

Check your product before shipping to make sure it is good.

Check during making to catch problems early.

Visit the factory to see if they follow the rules.

Test your product in a lab to make sure it is safe.

Register your product with Chinese agencies.

Your supplier should know about these rules. Ask your supplier to show proof of certifications before you ship your product. If you want to sell your product in other countries, make sure your supplier follows all safety and labeling rules.

Note: If you do not have the right certifications, you cannot sell or ship your product. Always check with your supplier before you start making your product in China.

Assembly & Supply Chain

You must manage assembly and the supply chain when you manufacture a product in China. Use custom manufacturing services for hard projects. Work with your supplier and talk clearly. Use project tools and talk often to stop mistakes.

You should:

Visit your supplier’s factory to see how they work.

Set clear rules for quality with your supplier.

Use outside inspectors for extra checks.

Build good relationships with your supplier for better results.

Have backup suppliers in case something goes wrong.

Do not put all assembly in one factory. Use different suppliers for different jobs if needed. This lowers risk and helps you control quality. Use third-party companies to move your product safely. Always check that your supplier follows shipping and customs rules.

Callout: A strong supply chain and a good assembly plan help you make your product in China with fewer problems.

Common Pitfalls

Miscommunication

Miscommunication is a big problem in rapid prototyping in China. Sometimes, your supplier says "yes" but does not really understand you. In China, "yes" can mean "I hear you," not "I agree." This can cause mistakes in your project. You may think your supplier will follow your plan, but they might have questions they do not ask.

Chinese suppliers may not ask questions because they want to show respect.

They might see you as a "boss," so they do not talk openly.

In China, friendship and casual talks are more important than contracts.

Saying things in different ways helps everyone understand better.

Visiting the factory shows you care and helps build trust.

Tip: Ask your supplier to repeat your instructions. Use pictures and easy words to explain what you want.

Incomplete Files

If your files are not complete, your project can be delayed. When you send files with missing details, your supplier cannot start making your prototype. Problems like missing drawings or files that do not open can stop the process.

If files are missing or not clear, there can be errors in PCB work.

If your files do not match, your supplier must wait for your answer.

These problems make it hard to get prices and pick a factory.

Write down any problems you know about to avoid mistakes.

Make sure assembly drawings are clear and approved before starting.

Note: Always check your files before sending them. Clear files help your project move faster.

Rushing the Process

If you rush rapid prototyping in China, you can make mistakes. Skipping steps or testing too fast means you might miss something important.

Missing details can cause problems that show up later.

If you skip quality checks, your prototype may not work well.

These mistakes can make your final product worse and cost more money.

Experts say to take your time, check your work, and test often.

Ask for changes if something is not right.

Alert: Be patient and test carefully. Do not skip steps, even if you want to finish quickly.

To do well when you manufacture a product in China, you need clear goals. Write down your plans and keep good records. Pick a China prototyping company that fits your project and protects your ideas. Test your prototype many times and use feedback to make it better. When you manufacture a product in China, work with your China prototyping company at every step. Make sure you protect your IP before sharing your designs. Always plan for quality checks and talk often with your China prototyping company. Before you manufacture a product in China, make a checklist, protect your IP, and go over your design with your China prototyping company. This way, you can manufacture a product in China with less risk and better results.

Tip: Try 3D printing and test your prototype to find problems early. Keep talking with your China prototyping company to fix issues fast and make it easier to manufacture a product in China.

FAQ

What files do you need to send to a China prototyping factory?

You need to send 3D CAD files (like STEP or IGS), 2D technical drawings, and a Bill of Materials. Always check with your factory about their preferred formats.

How can you protect your design from being copied in China?

Register your patents in China. Use strong NDAs with your factory. Only share the information needed for your prototype. Work with trusted partners and keep records of all agreements.

How long does it take to get a prototype from China?

Most simple prototypes take 3 to 7 days to make. Shipping to the US usually adds 6 to 10 days. Complex designs may take longer.

What is the best way to communicate with a Chinese factory?

Use clear, simple English. Add pictures or diagrams when possible. Ask your factory to repeat your instructions back to you. This helps avoid mistakes.

Can you use any material for your prototype in China?

You can choose from many materials like plastics, metals, and composites. Ask your factory which materials they have and which work best for your design.

LKprototype

LKprototype