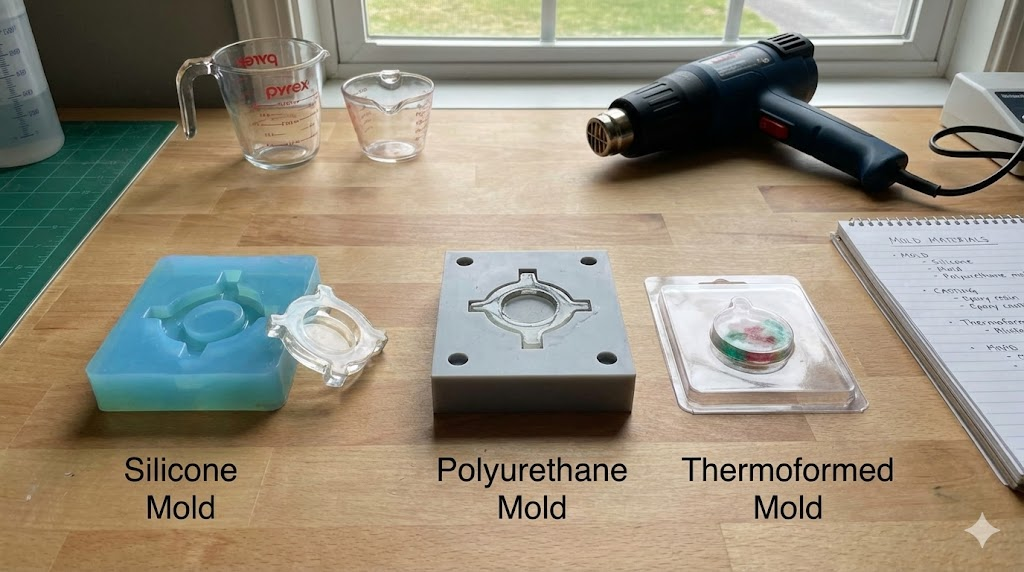

Silicone is often the best choice for epoxy resin mold material. Silicone provides flexibility and durability, making it easy to remove your project from the mold. When you pour resin into silicone molds, you quickly understand why they are favored by many. These molds are suitable for both beginners and experts. Silicone mold rubber and platinum-cured silicone mold rubber work exceptionally well with resin casting. If you plan to reuse a mold, silicone is an excellent option as it creates strong molds that last. Rigid molds like polyurethane mold rubber or plastic are ideal for hard shapes and can also help you save money. Choosing the right mold depends on your project requirements. You should consider the casting material and the curing time of your epoxy resins. Silicone molds are particularly advantageous when you desire intricate details. They also facilitate easy project removal and provide smooth finishes. Some tips for using resin in any mold include checking the main features of silicone molds. Additionally, it's essential to understand how rubber and epoxy interact. Knowing when to use rigid or flexible molds is crucial.

Remember: The right epoxy resin mold material is key to ensuring your resin project turns out well, whether you opt for tin-cured silicone mold rubber or polyurethane.

Key Takeaways

Silicone molds work best for most resin projects. They are flexible and can show small details well.

Polyurethane molds are good for bigger and simple shapes. They are strong and help when making many copies.

Plastic molds are cheap and good for one-time use. But they do not last long and do not show details as well as silicone or polyurethane molds.

Think about your project and how much detail you need before picking a mold. This helps you get the best results.

If you clean and care for your molds, they will last longer. This also makes your resin castings look better.

Which Mold Material Is Best for Epoxy Resin Casting?

Quick Answer for Beginners and Professionals

The best mold material depends on what you need for your project. You should think about how flexible, strong, and cheap the mold is. Silicone is a top pick for most resin projects. You can use silicone molds for art, jewelry, or detailed work. Silicone makes it easy to take out your project and gives a smooth finish. If you are just starting, silicone molds help stop sticking and tearing. People who do this a lot also like silicone because it lasts and keeps its shape.

Tip: Pick your mold based on your project’s size and how hard it is. Small, detailed things need soft molds. Big items might need hard molds for support.

When flexibility matters

You need a flexible mold for tiny details or tricky shapes. Silicone molds can bend and stretch, so you can take out your resin without breaking it. Rubber molds, like silicone, are good for projects that need easy removal. If you want to make jewelry or small crafts, silicone molds work best. The mold bends around your resin, so you don’t get cracks or chips.

When durability matters

If you want to use your mold many times, it needs to be strong. Silicone and polyurethane molds last longer than plastic ones. Silicone does not tear and stays good after lots of uses. Rubber molds can handle heat and do not lose their shape. Polyurethane molds are harder, so they are good for big or simple shapes. Hard molds are great for home decorations or making the same thing many times.

When cost matters

If you want to save money, cost is important. Plastic molds are cheaper than silicone or polyurethane. You can use things from home for simple resin projects. These molds are good for one-time or short projects. If you want better quality and detail, silicone molds cost more but last longer. Rubber molds are a better deal if you use them a lot. Always think about how much each part costs and how many times you will use your mold.

Here are things professionals look for when picking mold materials:

How flexible and non-stick the mold is

If it stays strong for big projects

If it lasts with lots of use and heat

If it is easy for beginners

If it fits the project’s size and difficulty

If it works for different kinds of projects

If it is good for the environment

Epoxy Resin Mold Materials Overview

What Is an Epoxy Resin Mold Material?

Definition of mold material in resin casting

When you do resin casting, you must pick a mold. The mold shapes your resin and helps you get the look you want. You can use silicone, polyurethane, or plastic molds. Each mold feels different and has its own strength. Silicone molds are soft and bend easily. Polyurethane molds are hard and keep their shape. Plastic molds are best for simple projects. Rubber molds, like silicone, let you take out your resin without breaking it. The mold you choose will change how easy it is to work with resin.

Relationship between epoxy resin and mold compatibility

Epoxy resin mold material should match your resin type. Some resins need molds that can handle heat or strong chemicals. Silicone works with most resins and does not stick. Polyurethane molds are good for strong and simple shapes. Rubber molds help you avoid cracks when you take out your resin. If you use the wrong mold, your resin might stick or not cure right. You want your mold to last and give you good results.

Why Mold Material Choice Matters in Resin Casting

Impact on surface quality

The mold you pick changes how your resin looks when finished. Silicone molds show tiny details and give a smooth, shiny finish. Hard molds, like plastic or polyurethane, may not show fine lines well. You might need to sand or polish your resin if you use a hard mold. Rubber molds help you get a clean look with less work.

Impact on demolding success

Demolding means taking your resin out of the mold. Silicone makes demolding easy because it bends and stretches. Hard molds need more care, and you might need a release spray. If you want to make many pieces, durability matters. Silicone molds last longer and keep working after many uses. The table below shows how silicone and hard molds compare:

Feature | Silicone Molds | Rigid Molds |

|---|---|---|

Demolding behavior | Flexible, easy release of intricate details | Needs careful removal, may need parting lines |

Detail reproduction | Shows fine details and textures well | May not show fine details as well |

Chemical compatibility | Works with most resin types, handles heat | Must resist chemicals and heat |

Durability & reuse | Can handle many pours, stays good for long use | Shorter life, may wear out faster |

Dimensional stability | May bend under pressure, less exact | Keeps exact shape for repeat projects |

Finish & postwork | Needs less sanding, can be glossy | May need lots of sanding or polishing |

Tip: Pick your epoxy resin mold material based on the finish and how easy it is to remove your project. This helps you get the best results for your resin casting.

Silicone Molds for Epoxy Resin: When and Why to Use Them

Key Advantages of Silicone Molds

High flexibility for easy demolding

Silicone molds make resin casting simple. The rubber can bend and stretch a lot. This means you can take out your resin project easily. You do not need special tools to remove it. The mold’s flexibility stops cracks and chips from happening. You do not have to worry about breaking your project. Every time, silicone gives a smooth release.

Excellent detail reproduction

Silicone shows small details and textures very well. If you want to make art or jewelry, silicone is a good choice. It copies every line and pattern from your design. The rubber surface makes sharp edges and clear shapes. This is why silicone molds are best for perfect detail.

Tip: Pick silicone molds if you want easy removal and great detail. You will get better results and save time.

Here are the main advantages of silicone molds for epoxy resin casting:

You can remove resin easily without special tools

You can use the mold many times

Silicone shows fine details for high-quality results

Durability and Reusability of Silicone Molds

Typical mold lifespan

You can use silicone molds again and again, but not forever. How long they last depends on your resin and how you cast. Some molds wear out faster with strong chemicals or heat. You should plan to get new molds after some uses. Changing molds often keeps your projects looking nice.

Silicone molds do not last forever.

How long they last depends on resin and casting methods.

You need to replace molds often because they wear out.

Factors affecting wear

You can make your silicone molds last longer by cleaning them gently. Store them flat so they do not bend. Do not stretch the rubber too much. Overfilling the mold can change its shape. Use the right resin and let it cure for the right time. If you see tears or warping, get a new mold.

Limitations of Silicone Molds

Tear strength concerns

Silicone molds can rip if you are rough with them. The rubber is soft, so sharp tools or too much force can hurt the mold. Use support for big or heavy resin projects. The mold can change shape if you overfill or bend it too much.

Air bubbles can show up in your resin. You can stop this by warming the resin and using a heat gun after pouring.

Sticky or soft resin can happen if you mix resin and hardener wrong or do not wait long enough.

The mold can change shape. You can stop this by using support and not overfilling.

Cost compared to plastic molds

Silicone molds cost more than plastic or hard molds. You pay more for better quality and longer use. If you only need a mold one time, plastic or polyurethane molds are cheaper. For many uses and great detail, silicone is worth the price.

Mold Material | Flexibility | Detail Quality | Durability | Cost |

|---|---|---|---|---|

Silicone | High | Excellent | Good | Higher |

Polyurethane | Low | Moderate | Good | Moderate |

Plastic | Low | Basic | Low | Low |

Note: Think about cost, how long the mold lasts, and quality when you pick your epoxy resin mold material.

Polyurethane Molds for Epoxy Resin: Strength and Limitations

Structural Characteristics of Polyurethane Molds

Rigidity and dimensional stability

Polyurethane molds are much harder than silicone molds. This hardness helps your resin project keep its shape. The mold gives strong support when you pour resin. It does not bend or move like silicone. This is good for parts that must stay the same size.

Resistance to deformation

Polyurethane molds do not change shape after many uses. You can use them for projects that need to last a long time. The mold stands up to pressure and does not wear out fast. The table below shows how polyurethane is different from other molds:

Characteristic | Description |

|---|---|

Excellent chemical resistance | Good for places with oils, grease, and chemicals. |

Exceptional abrasion resistance | Stays strong in jobs with lots of rubbing. |

High mechanical strength | Keeps its shape and works well. |

Demolding Challenges with Polyurethane Molds

Need for draft angles

You need to add draft angles to your resin project. Draft angles help you take the resin out of the mold. If you do not use them, you might break your project or the mold.

Use of release agents

You must use a release agent with polyurethane molds. This stops the resin from sticking to the mold. If you pick the wrong release agent, the resin can tear or stick. Here are some common problems when taking resin out:

Mold release agents do not always work with every resin or mold.

Molds that are too hard or have tricky shapes are hard to use.

If you take out the resin too soon, it can break.

Typical Applications for Polyurethane Molds

Simple geometry parts

Polyurethane molds are good for resin projects with easy shapes. These molds work best when you do not need tiny details. If you want to make the same part many times, polyurethane is a good choice.

Repetitive production needs

Polyurethane molds are great for making lots of the same resin part. The mold keeps its shape and lasts through many uses. This makes polyurethane smart for jobs where you need many copies.

Tip: Pick polyurethane molds if you want strong, hard molds for simple shapes and lots of projects. You will get the same results every time and the mold will last a long time.

Plastic Molds for Epoxy Resin: Low-Cost and Simple Applications

Common Plastic Mold Types Used for Epoxy Resin

Injection-molded plastic molds

You can find injection-molded plastic molds in many craft stores. These molds come in simple shapes like circles, squares, and hearts. You can use them for basic resin casting projects. The hard plastic gives your resin a solid form. You do not get much flexibility, but you can make many copies of the same shape.

DIY plastic mold containers

You can also make your own plastic molds at home. Many people use food containers, packaging trays, or even bottle caps as molds. These DIY options work well for small projects or when you want to try new ideas. You can cut or shape the plastic to fit your needs. This method saves money and lets you recycle old containers.

Tip: If you want more detail or flexibility, silicone molds or rubber molds work better than plastic.

Surface Finish and Detail Limitations

Smoothness constraints

Plastic molds give your resin a smooth surface, but not as glossy as silicone. You may see small lines or marks from the mold. You might need to sand or polish your resin after demolding. The finish depends on the quality of the plastic mold material.

Limited texture reproduction

Plastic molds cannot show fine details like rubber or silicone. If you want to copy textures or tiny patterns, you will not get the best results with plastic. The table below compares how different mold materials capture detail and finish:

Feature | Silicone Molds | Rigid Molds (Plastic/Polyurethane) |

|---|---|---|

Detail Capture | Excellent – fine lines | Good but limited |

Surface Finish | Smooth and glossy | May need extra finishing |

Disposable vs Reusable Plastic Molds

Single-use scenarios

You can use plastic molds for one-time projects. If you want to test a new resin or make a quick gift, plastic works well. You do not have to worry about durability or cleaning. After the resin cures, you can throw away the mold.

Short production runs

Plastic molds also help with short production runs. You can make a few copies before the mold wears out. If you need to make many items, you should choose a stronger mold material like silicone or polyurethane. Rubber molds last longer and give better results for repeated casting.

Note: Plastic molds offer a cheap way to start resin casting, but they have limits in detail, durability, and demolding.

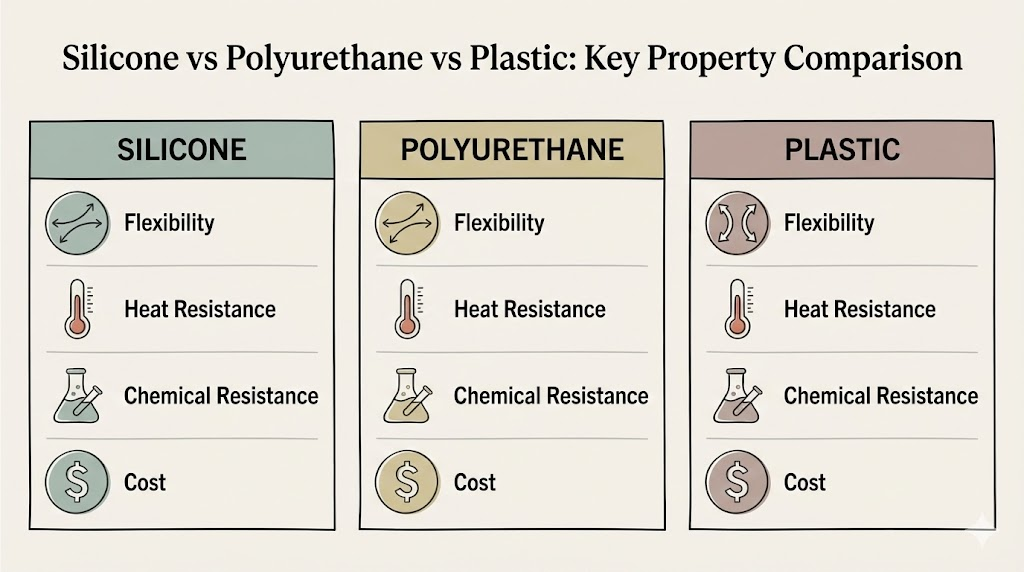

Silicone vs Polyurethane vs Plastic: Key Property Comparison

Flexibility and Demolding Performance

Ease of part removal

You want to take your resin out of the mold without breaking it. Silicone molds can bend and stretch a lot. This makes it easy to pop out your resin project. Hard molds, like polyurethane and plastic, do not bend at all. You have to use more force or a release spray to get your resin out. This can make things harder for people who are new to resin casting.

Feature | Silicone Molds | Rigid Molds (Polyurethane/Plastic) |

|---|---|---|

Flexibility | High – bends and stretches | None – completely stiff |

Ease of Demolding | Easy – gentle flex to release | Difficult – needs force or agent |

Risk of damage

Flexible rubber molds help stop cracks or chips in your resin. Hard molds can hurt your project when you try to take it out. You might also scratch or break the mold itself.

Durability and Mold Lifespan

Number of casting cycles

Silicone molds can be used many times. Some platinum-cured silicone molds last for years if you are careful. Polyurethane molds also last a long time but do not show small details as well. Plastic molds can get scratched or bent after just a few uses.

Silicone molds: can be used hundreds of times with care

Polyurethane: good for many uses, best for simple shapes

Plastic: does not last long, best for quick or one-time projects

Material fatigue

Rubber molds like silicone do not wear out fast. They can handle heat, sunlight, and water. Plastic molds get weak quickly and can bend or crack.

Detail Accuracy and Shrinkage

Surface fidelity

Silicone molds show tiny lines and textures very well. Your resin comes out smooth and nice. Polyurethane and plastic molds do not show as much detail. You might need to sand or polish your resin after you take it out.

Dimensional stability

Hard molds keep their shape, so your resin stays the right size. Silicone molds can bend a little, but they still work for most resin projects.

Cost and Accessibility

Initial material cost

Silicone molds cost more than plastic molds. Polyurethane prices change depending on how you use them. You can make silicone molds fast, which helps when you start a new project.

Long-term cost per part

If you make lots of resin pieces, silicone molds save you money over time. Plastic molds are cheap at first, but you have to buy new ones often. Polyurethane molds are a good choice if you make simple shapes again and again.

Tip: For small batches, silicone molds give you the best quality and value.

Safety and Ease of Use

Handling requirements

Pick platinum-cure silicone if your project touches food or skin. Make sure your mold can take the heat from curing resin. Always work where air can move because resin can make strong smells.

Beginner friendliness

Silicone molds are simple for beginners to use. You do not need special tools or skills. Hard molds need more practice and care. Plastic molds are easy but do not last very long.

Note: Always check that your epoxy resin mold material is safe and made for resin casting.

Epoxy Resin Mold Material Comparison Table

Side-by-Side Property Comparison

Silicone vs Polyurethane vs Plastic

You need to choose the best mold for your resin project. The right epoxy resin mold material helps you get good results. Each mold type has things it does well and things it does not. You should think about how flexible the mold is, how easy it is to take out your resin, how long the mold lasts, how well it shows details, and how much it costs.

Here is a table that shows how silicone, polyurethane, and plastic molds are different:

Property | Silicone Molds | Polyurethane Molds | Plastic Molds |

|---|---|---|---|

Flexibility | Superior for intricate projects | Rigid, best for simple shapes | Rigid, limited flexibility |

Ease of Demolding | Gentle flex needed | Needs mold-release spray | Needs force or spray |

Durability | Lasts through many pours, may tear | Good for repeated casting, strong | Scratches/warps after few uses |

Detail Capture | Excels at fine textures and details | Moderate, not for complex detail | Struggles with fine detail |

Cost | Moderate price, affordable for hobbyists | Moderate, depends on mold size | Low, best for short runs |

Rubber Quality | Soft, stretches easily | Hard, keeps shape | Hard, can crack |

Cure Compatibility | Works with most resin types | Good for strong resins | May react with some resins |

Tip: If you want to make jewelry or art with tiny details, use silicone molds. For simple shapes and making many copies, polyurethane molds are strong and last longer. Plastic molds are cheap and good for quick or one-time projects.

You should also think about how easy it is to clean each mold. Silicone molds are easy to wash. Polyurethane molds need more work to clean. Plastic molds can get sticky after a few uses. Rubber molds like silicone and polyurethane help you take out your resin without cracks. If you want your resin to cure right, pick a mold that works with your resin.

A good mold makes resin casting easier for you. You get better results and do not have to fix as many mistakes. When you pick your epoxy resin mold material, look at the table and choose what is most important for your project.

How to Choose the Right Mold Material for Your Epoxy Resin Project

Project Type and Part Size

Small decorative parts

If you want to make small decorative items, you should look for a mold that gives you flexibility and detail. Silicone molds work well for jewelry, charms, or keychains. The rubber stretches, so you can remove your resin without breaking it. You get smooth edges and clear shapes. For tiny parts, you do not want rigid molds because they can crack your project during demolding.

Large structural components

For large pieces, you need a mold that supports the weight of the resin. Polyurethane and hard rubber molds give you strength and durability. These molds keep their shape and help your resin cure evenly. You can use them for trays, panels, or art pieces that need to stay flat and strong.

Required Detail Level and Complexity

Fine textures

When your project needs fine textures or complex designs, you should choose a mold material that captures every line. Casting materials like silicone and soft rubber show small details and prevent air bubbles. Their lower viscosity helps the resin fill every part of the mold, so you get sharp results.

Simple flat surfaces

If you want simple, flat shapes, you can use plastic or rigid molds. These molds do not show as much detail, but they work for basic forms. You may need to sand your resin after demolding to get a smooth finish.

Budget and Production Volume

One-off casting

If you only need one resin piece, you can use a cheap plastic mold or a DIY rubber container. You do not need to pay for premium features. This helps you manage your budget.

Low-volume production

For a few copies, silicone molds give you good value. You can reuse the rubber mold many times. Production volume affects your choice. If you plan to make many items, pick a mold that lasts and fits your budget.

Understanding your process helps you save money.

Avoid extra features you do not need.

The number of parts you make changes the best mold material for you.

Beginner vs Professional Use

DIY hobbyists

If you are a hobbyist, you want a mold that is easy to use and not expensive. Flexible rubber like silicone helps you handle resin casting with less stress. You get better detail and easy demolding.

Industrial and commercial users

If you work in a factory or need many resin parts, you need molds with high durability. Industrial users often choose metal or strong rubber molds for long life and precision. These molds work well for high-volume production and keep their shape after many uses.

Tip: Think about your project’s size, detail, and how many pieces you want to make. This helps you pick the right epoxy resin mold material for your needs.

Best Practices for Working with Epoxy Resin Molds

Best Practices for Silicone Molds

Proper mold release usage

You should always check if your silicone mold needs a release agent. Most silicone molds do not need one because rubber is naturally non-stick. If you notice your resin sticking, use a small amount of mold release spray. Overpour your mold slightly because resin shrinks a little as it cures. This helps you get a full shape every time.

Storage and cleaning tips

Keep your silicone molds clean to make them last longer. Wash your mold with soap and water after each use. Shake out extra water and let the rubber dry flat, away from sunlight or heat. Store your mold in a cool, dry place. Cover the mold with a box or container while your resin cures to keep out dust and hair. Demold carefully by peeling the rubber away from your project. This prevents tears and keeps your mold material strong.

Tip: Use a heat gun over the surface of the mold to remove bubbles before the resin cures.

Best Practices for Polyurethane Molds

Draft angle design

When you use polyurethane molds, design your casting with draft angles. This means you make the sides of your project slightly slanted. Draft angles help you remove the resin without damaging the mold. Rigid molds like polyurethane need this step for easy demolding.

Controlled demolding methods

Mix your rubber components well before pouring. Do not change the mix ratio. Always let the mold release dry before you pour resin. Wear gloves and a respirator for safety. Avoid moisture to stop bubbles from forming in your casting. Demold slowly and gently to protect the durability of your mold.

Best Practices for Plastic Molds

Preventing resin adhesion

Plastic molds can stick to resin. Always spray a mold release before pouring. Choose the right type of resin for your project. Work in a clean, well-ventilated area and cover your workspace with a mat.

Mold replacement planning

Plastic molds wear out quickly. Plan to replace them after a few uses. Clean your mold with mild soap between castings to keep the rubber surface smooth. This helps you get better results and keeps your epoxy resin mold material working well.

Note: Good care and planning help you get the most out of every mold and improve your resin casting results.

Common Problems When Using Epoxy Resin Molds and How to Fix Them

Sticking and Demolding Issues

Causes of sticking

You may find your resin sticks to the mold or does not come out easily. This happens for several reasons. Sometimes, you pour resin on an uneven surface, which causes bending. High heat from large pours can soften silicone and make it lose shape. Thin rubber molds or low-quality silicone molds can warp or tear. If you remove your project before it cures, the resin can deform. Incorrect mixing or cold, humid conditions can leave the resin sticky. Old or damaged molds lose their non-stick surface. Overheating with a torch can also cause sticking.

Cause | Description | Solution |

|---|---|---|

Uneven surface | Resin pools and bends | Level your workspace before pouring |

High internal heat | Silicone softens and bends | Pour in smaller batches, avoid over-pouring |

Thin or low-quality molds | Warping or tearing | Use thicker, premium silicone molds |

Early demolding | Resin deforms | Wait for full cure before removing |

Improper mixing | Sticky, uncured resin | Mix thoroughly and use correct ratios |

Humidity/temperature issues | Tacky surfaces | Work in warm, dry conditions |

Old or damaged molds | Loss of non-stick surface | Replace or rotate molds |

Overuse of heat gun/torch | Resin bonds to silicone | Use quick, sweeping motions |

Practical solutions

You can fix sticking and demolding problems by following these steps:

Always check your workspace with a level before you start.

Use high-quality, thick rubber molds for better durability.

Mix your resin with a digital scale and follow the right ratio.

Wait for the full cure time before demolding.

Keep your room at 25–30°C with low humidity.

Clean your mold after each use and replace it when worn.

Use a heat gun carefully and never torch the mold walls.

Tip: Patience helps you avoid most demolding issues. Let your resin cure fully for best results.

Surface Defects and Air Bubbles

Entrapped air causes

Air bubbles can appear in your resin during casting. You may see them if you mix too fast or pour too quickly. Cold molds or resin can trap air. Humid or cold rooms slow the cure and cause bubbles. Thick layers of resin hold more air.

Prevention techniques

You can prevent bubbles and surface defects with these methods:

Warm your resin and mold before pouring.

Mix slowly and pour in thin layers.

Use a heat gun or torch to pop surface bubbles.

Spray isopropyl alcohol to break surface tension.

Try a vacuum chamber or pressure pot for fewer bubbles.

Work in a dry, warm room.

Build thick castings in several layers.

Note: Coloring your resin can help hide small bubbles if they remain.

Mold Wear and Deformation

Signs of mold degradation

You may notice your mold material wearing out if you see cracks, tears, or warping. The rubber may lose its shine or become sticky. Old molds can cause your resin to stick or lose detail. Rigid molds may crack or lose shape after many uses.

When to replace the mold

Replace your mold when you see damage or if your resin projects do not release cleanly. If you notice loss of detail or the mold feels soft, it is time for a new one. Regular cleaning and careful storage help your molds last longer, but all molds wear out over time.

Remember: Good care and timely replacement keep your epoxy resin mold material working well for every casting.

Now you know silicone is best for most resin molds. Silicone molds bend and make it easy to take out your project. They also show small details very well. Rubber molds help you get smooth resin pieces that last a long time. Polyurethane and hard molds are good for big resin projects that need extra support. Always look at the comparison table before picking a mold. This helps you cure your resin the right way and have fun with each project. Try using new rubber molds and watch your resin projects get better!

LKprototype

LKprototype