Need to quickly convert your CAD designs into physical models? Rapid prototyping services offer a fast and reliable way to create prototypes for testing and validation. This article dives into the different technologies available, the materials you can use, and how these services can accelerate your product development.

Key Takeaways

Rapid prototyping is essential for quickly producing functional prototypes from CAD models, enabling early design testing and iterations.

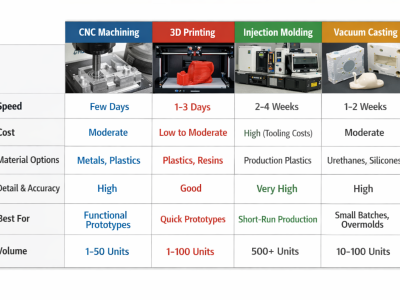

Key technologies in rapid prototyping, such as CNC machining, 3D printing, and injection molding, provide flexibility and efficiency for both low and high-volume productions.

Selecting appropriate materials is crucial for prototype characteristics, and rapid prototyping services significantly accelerate product development cycles across various industries.

Understanding Rapid Prototyping

Rapid prototyping is a technique employed to swiftly create physical prototypes directly from computer-aided design (CAD) models, which act as digital templates for manufacturing. This method plays an essential role for rapid prototyping companies by facilitating functional testing, securing design approvals, and permitting swift iterations within the product development process. By generating prototypes that closely mimic the final product, this approach significantly improves design precision and aids in uncovering potential problems early on in the product development cycle.

By adopting rapid prototyping practices, manufacturers gain the ability to evaluate and refine their designs before commencing full-scale production. This iterative procedure is not just conducive to informed redesigns, but also assists in rectifying any design flaws at an initial stage—ultimately conserving both time and financial resources. Companies aiming to fully exploit rapid prototyping’s advantages need access to suitable tools and machinery as well as specialized knowledge.

As a crucial intermediary between conceptual digital designs and tangible products, rapid prototyping has become integral within contemporary cycles of developing new items. It offers invaluable assistance regardless of whether you are creating novel consumer electronics or intricate industrial parts. Providing a prompt avenue for transforming inventive concepts into concrete reality with efficiency.

Key Rapid Prototyping Technologies

The rapid prototyping sector is propelled by several pivotal technologies, each with distinctive advantages and specific uses. Techniques like CNC machining, 3D printing, and injection molding are forefront methods that facilitate the swift creation of top-notch prototypes. These approaches satisfy various production needs ranging from crafting a limited number of prototypes to scaling up for mass manufacturing.

CNC machining stands out for its exceptional precision and is extensively utilized in fabricating both metallic and plastic prototype components. Digital manufacturing advances have Bolstered this industry through 3D printing methodologies such as FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering), which excel at accommodating on-demand fabrication requirements.

Injection molding has proved effective in quickly generating high-quality parts while frequently leveraging rapid tooling strategies to adhere to demanding material specifications and mechanical properties.

CNC Machining for Rapid Prototyping

Rapid prototyping heavily relies on CNC machining, which is celebrated for crafting prototypes of full strength that are apt for engineering evaluations. This process encompasses both CNC milling and turning to generate high-quality, functional prototypes out of a diverse range of raw materials. The adaptability inherent in CNC machining facilitates the creation of parts made from metal or plastic with outstanding accuracy.

When it comes to enhancing the endurance and visual appeal of prototypes, CNC machining presents multiple finishing techniques such as anodizing and chromate plating. Even though obtaining CNC machined components takes longer than 3D printed ones—usually within a week’s time—the precision and quality offered by this production method are unmatched.

With its capacity to fabricate quantities ranging from just a handful up to over 10,000 pieces, CNC machining proves adaptable enough for low-volume through high-volume needs alike. Its proficiency in working with numerous substances including metals and various plastics cements its status as a reliable approach for manufacturing strong and reliable prototypes.

3D Printing Techniques

The advent of 3D printing has transformed the field of rapid prototyping, facilitating the fabrication of intricate components and complex designs while significantly reducing lead times. Within rapid prototyping, there are three primary methodologies: Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM). Each offers unique benefits tailored for different uses.

Among these, Fused Deposition Modeling is widely embraced because it employs engineered thermoplastics that yield robust and functional prototypes. Conversely, Selective Laser Sintering stands out due to its capacity to deliver finely detailed parts at a more economical rate. Hence it’s an efficient option for numerous endeavors.

The versatility and efficiency afforded by these 3D printing strategies make them indispensable across diverse sectors requiring prototyping services. They provide scalable options—from crafting a single prototype to undergoing several iterations—ensuring adaptability in meeting bespoke requirements with 3D printed results.

Injection Molding

Injection molding is a pivotal rapid prototyping process, notable for its exceptional consistency and capacity to produce parts that are very close to their final design. It excels in scenarios where prototypes must adhere to stringent material specifications or mechanical properties, often outperforming alternative methods such as additive manufacturing. Services encompass both low-volume prototype creation and high-volume production runs, thereby accommodating varying scales of production needs.

The technique distinguishes itself through its swift execution, with the capability of fabricating parts within a mere 10 business days. Services like Quick Turn Molding can expedite this process. By delivering components in an impressive timeframe of just five days. Such efficiency is enhanced by various finishing techniques including pad printing, laser engraving, and integration of threaded inserts, which guarantee that the resulting prototypes satisfy all visual and practical criteria.

For rapid prototyping via injection molding, materials commonly used consist primarily of aluminum and plastic variants. These offer diverse attributes tailored for specific use cases. Not only does this approach yield parts similar to those found in full-scale production, but it also facilitates professional engineering assessments aimed at bolstering overall part quality and manufacturing efficiency throughout the development cycle.

Material Options for Rapid Prototyping

Choosing the appropriate material is essential in rapid prototyping because it influences the prototype’s attributes, including its strength, flexibility, and capacity to withstand temperature changes. A range of materials such as aluminum, alloy steel, brass and various engineering plastics like ABS (Acrylonitrile Butadiene Styrene), PC (Polycarbonate), and ULTEM are utilized for their specific properties that align with the requirements needed for a given prototype to fulfill its function and achieve desired aesthetics.

Conducting functional tests during the prototyping phase is vital in uncovering design issues at an early stage while also verifying safety compliance. The possibility of going through numerous revisions supports enhancement until the final product meets all necessary standards ensuring both user safety and functionality.

The realm of additive manufacturing has broadened available options regarding materials by allowing multi-material prototypes with differing characteristics tailored specifically for individual functional demands. This advancement provides designers with opportunities to explore varying combinations of substances leading up to finding one that maximizes performance aligned perfectly with what’s intended from them in application contexts.

Advantages of Using Rapid Prototyping Services

Rapid prototyping is a dynamic process that greatly streamlines the product development cycle. It enables teams to quickly generate and evaluate 3D models, promptly incorporating user feedback and facilitating swift modifications. This method places emphasis on the speedy generation of initial prototypes for immediate iteration based on real-world input.

The capacity to carry out functional testing with physical prototypes stands as a principal benefit offered by rapid prototyping services. It allows detection of potential problems related to fit and function before entering mass production, saving both time and costs while guaranteeing that final products satisfy all technical specifications and compliance requirements. Rapid prototyping provides an avenue for market testing, granting companies the opportunity to hone their products through direct consumer insights.

Embracing this iterative approach ensures focus remains on integral features valued by users, resulting in an enhanced product primed for launch into the marketplace. Rapid prototyping’s facility for expeditious refinements serves as leverage in keeping products relevant and tailored according to customer preferences.

Rapid Prototyping Process at LKprototype

LKprototype provides an extensive array of rapid prototyping services, capable of creating both metal and plastic prototypes with swift quotation delivery. Their manufacturing proficiency encompasses a variety of methods such as CNC machining, 3D printing, vacuum molding, injection molding, and sheet metal fabrication. This versatility guarantees the ability to produce functional prototypes in sessions that can be as brief as three hours.

The procedure at LKprototype is streamlined for efficiency—starting from uploading the initial CAD file to executing the final delivery of superior-quality prototype models. With this well-organized process, each project receives meticulous attention and expedited handling tailored to satisfy client-specific requirements.

Uploading Your CAD File

At LKprototype, initiating the rapid prototyping journey begins with uploading your CAD file. It’s essential to choose a suitable manufacturing process beforehand to guarantee that the prototype will be accurate and compatible with the intended design. This early decision is pivotal as it influences both the viability and prospective triumph of creating a prototype.

Once you submit your CAD file, this triggers an in-depth analysis of the manufacturing requirements along with a subsequent quotation phase. During this stage, customers receive precise insights into both expenses and timeframes associated with their project, which assists them in making well-informed choices moving forward.

Manufacturing Analysis and Quotation

Upon submitting a CAD file, LKprototype offers an immediate pricing and manufacturing assessment integral to their rapid prototyping offerings. Clients can expect to receive a swift quotation within 24 hours of their inquiry. Enhanced algorithms have been instrumental in curtailing the time required for quotations, enhancing both efficiency and the client experience.

Each project’s unique demands govern the comprehensive quote and analysis provided for manufacturing services. This personalized approach guarantees that clients obtain solutions precisely aligned with their requirements, promoting optimization of both production timelines and expenses by refining precision in the production process.

Production and Delivery

Following the acceptance of a quote, LKprototype initiates production swiftly. The company boasts in-house manufacturing capabilities that enable expedited delivery, with the potential for prototypes to be crafted within merely twenty-four hours. This quick pace is maintained across their services, as they are equally capable of creating prototypes for sheet metal fabrication within this condensed period.

The engineering team at LKprototype plays an instrumental role in supporting production endeavors by optimizing both quality and cost-efficiency. To refine the final product, post-processing procedures are conducted to guarantee that every aspect aligns with specific requirements and satisfies client demands.

Real-World Applications of Rapid Prototyping

Various industries utilize rapid prototyping, including the automotive, aerospace, healthcare, industrial machinery and consumer electronics sectors. Companies such as Dblitz and Quickparts provide these services to fields like construction, agriculture, medical technology, electronics plus energy and gas demonstrating its wide-ranging use and significance in contemporary manufacturing processes.

Within the realm of healthcare, biocompatible materials are essential when crafting safe medical devices or implants Rapid prototyping propels product advancement by allowing for swift examination iteration of designs which is critical in ensuring adherence to strict safety protocols performance standards.

Rapid prototyping promotes engagement with users by incorporating feedback from stakeholders and potential consumers into design iterations. This cycle helps ensure that upon completion the final product resonates with user necessities expectations thereby bolstering its market appeal eventual success.

Why Choose LKprototype for Your Rapid Prototyping Needs?

LKprototype is recognized as a premier entity in the rapid prototyping industry, acclaimed for its adaptability, superior quality output, and expedited completion of projects. The absence of minimum order prerequisites enables clients to initiate prototyping endeavors irrespective of project size, thereby facilitating both smaller enterprises and larger corporations. Holding several ISO certifications substantiates their dedication to maintaining top-tier quality management systems.

The company’s reputation is Bolstered by its swift production capabilities. Components that have been machined can be dispatched within just one day. LKprototype maintains an impressive rate of high-quality production, which ensures all prototypes meet exacting standards, offering customers dependable and precise products.

In summarizing their services portfolio, speed in delivery merged with uncompromised quality along with adaptable processes positions LKprototype at the forefront for satisfying diverse requirements associated with rapid prototyping effectively.

Case Study: Accelerating Product Development with Rapid Prototyping

An illustrative example is provided by a client in the medical device sector who was pressed to expedite their product development due to pressing market needs. The client took advantage of rapid prototyping techniques and managed to introduce their medical device into the marketplace much more swiftly than with conventional approaches, completing this phase in less than three weeks.

During the prototyping stage, a total of nine prototypes were created. This allowed for numerous iterations that facilitated prompt enhancements at each step. Consequently, this ensured that the resulting product conformed to all necessary functional and compliance standards.

By employing rapid prototyping methods, the client could effectively meet urgent healthcare demands by delivering an essential medical device faster and with greater efficiency. This case study underscores how transformative rapid prototyping can be for expediting product development cycles and achieving swifter time-to-market outcomes.

Summary

In summary, rapid prototyping is a powerful tool that accelerates product development cycles, allowing for quick iterations and functional testing. With technologies like CNC machining, 3D printing, and injection molding, businesses can create high-quality prototypes efficiently. LKprototype offers exceptional rapid prototyping services, with a focus on speed, quality, and flexibility. By leveraging these capabilities, companies can bring innovative products to market faster and more effectively.

Frequently Asked Questions

How much does rapid prototyping cost?

Rapid prototyping costs can range from $50 to $500 for simple prototypes, while larger metal parts can significantly increase the cost to several thousand dollars per iteration.

Therefore, the overall expense depends on the complexity and materials used in the prototype.

What are rapid prototyping services?

Rapid prototyping services involve quickly creating physical models or prototypes using techniques such as 3D printing and CAD data. This process accelerates design and production by enabling the rapid fabrication of parts or assemblies.

What is the minimum order quantity for LKprototype?

LKprototype does not require a minimum order quantity, allowing clients to initiate projects of any scale.

This flexibility is beneficial for both small and large businesses.

How quickly can LKprototype deliver machined parts?

LKprototype can deliver machined parts in as quickly as one day, ensuring prompt service for urgent projects.

What certifications does LKprototype's factory hold?

LKprototype’s factory holds ISO 9001 and ISO 13485 certifications, demonstrating its commitment to quality management systems and excellence in production.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype