Automotive CNC machining plays a crucial role in manufacturing precise and reliable car parts. From engine components to suspension systems, this technology enhances vehicle performance and efficiency. Read on to discover its applications, benefits, and why it’s vital in the automotive world.

Key Takeaways

CNC machining is essential in automotive manufacturing for producing high-precision components, including engine parts, transmission elements, and suspension systems, enhancing overall vehicle performance and safety.

Advanced technologies, such as AI and IoT, are transforming CNC machining by improving operational efficiency, precision, and integration in the automotive sector, enabling rapid prototyping and smart manufacturing practices.

Sustainable practices in CNC machining contribute to reducing waste and energy consumption, supporting eco-friendly manufacturing goals and the circular economy within the automotive industry.

Understanding Automotive CNC Machining

CNC machining, also known as Computer Numerical Control machining, is a vital manufacturing method in which computer systems guide machine tools with high precision to fabricate automotive components. This technique has become essential within the automotive sector by significantly improving vehicle performance, safety, and efficiency due to its meticulous production capacity. By enabling the generation of complex parts that adhere to strict tolerances, CNC machining ensures that these components fit flawlessly and perform exceptionally when incorporated into vehicles. The utilization of specialized computer software directs CNC machinery movements, which allows for crafting intricate pieces that align precisely with required specifications—an essential aspect for vehicular applications.

The significance of CNC machining extends to producing tangible prototypes which afford automotive designers the opportunity to experiment with concepts and discover potential problems before committing to large-scale production. Such prototyping plays a crucial role in validating design models while guaranteeing both proper fitment and functionality.

The integration of cutting-edge prototype creation alongside component fabrication—both characterized by their adherence to stringent tolerance levels—has transformed the landscape of auto industry practices. As such, CNC machining represents an irreplaceable facet in contemporary processes related to car manufacturing.

Key Components Produced with CNC Machining

The process of CNC machining plays a pivotal role in the creation of numerous automotive parts, encompassing engine blocks, transmission gears, and elements of the suspension system. It guarantees both elevated precision and heightened efficiency during production. To its use for internal components, this technology is instrumental in fabricating body and chassis parts including body panels as well as frame pieces that are essential for preserving structural integrity and adhering to rigorous safety regulations.

Employing CNC technology in the manufacture of these automotive components ensures consistent quality across all products. This consistency underscores why CNC machining has become an indispensable element in generating top-tier automotive parts with reliability at their core.

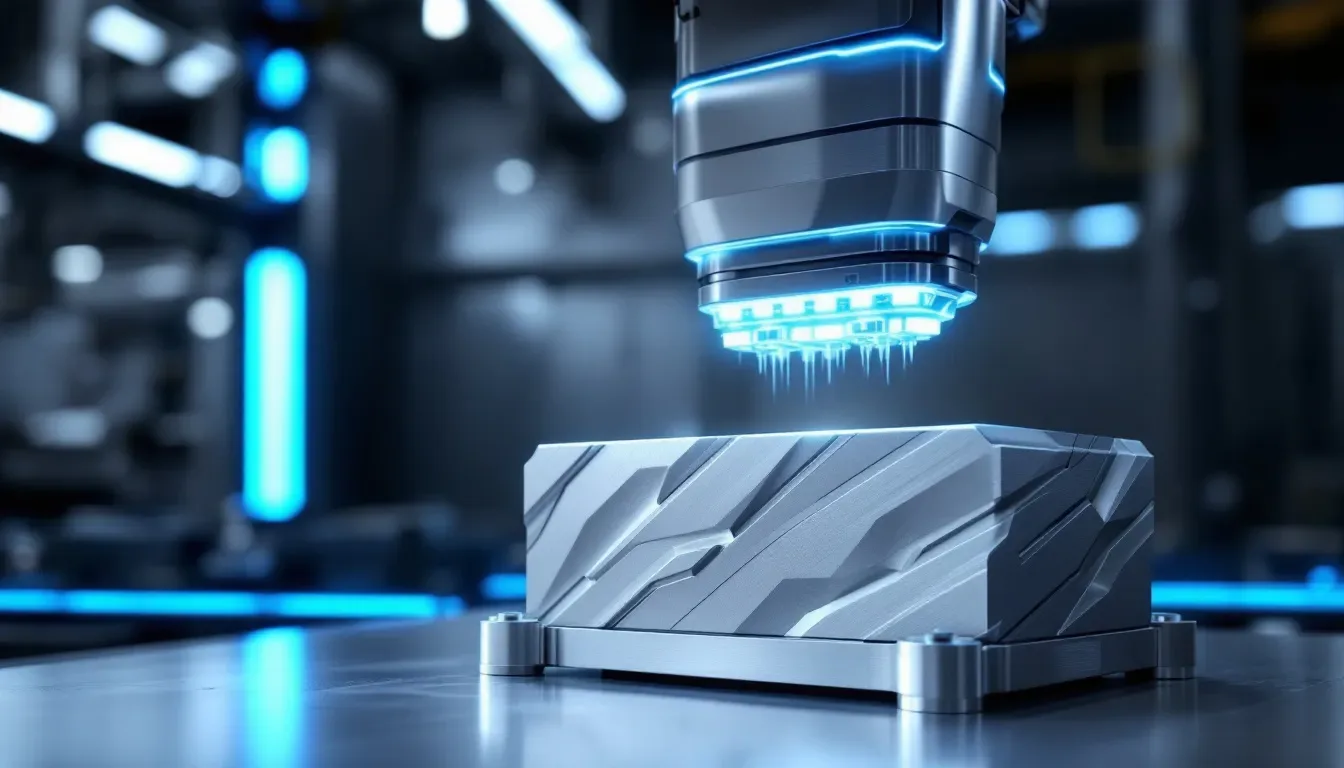

Engine Components

CNC machining plays a crucial role in the production of vital engine components, which include engine blocks, cylinder heads, and pistons for engine blocks. For crafting these parts with great precision and dependability, CNC milling machines are frequently utilized.

Materials selected for creating engine elements encompass aluminum alloys along with cast iron, steel alloys, and titanium alloys, each picked due to their unique attributes. Notably preferred materials consist of standard grades of cast iron like G3000 and G3500, as well as aluminum variants such as 356-T6 and A356-T6 owing to their combination of light weightiness and robustness. Titanium’s impressive ratio of strength-to-weight alongside heat resistance makes it an ideal material for fabricating high-performance motor componentry.

The precision achievable through CNC milling is critical in securing not only the functionality but also the durability and consistent reliability of automotive part assemblies. This meticulous attention to detail extends down to piston clearance tolerances that span from 0.0005 inches up to 0.0015 inches.

Transmission Parts

Components for transmission systems such as gear shafts, clutch parts, and transmission housings are essential items manufactured with CNC machining. To guarantee the robustness and functionality of the gearbox, these elements must adhere to precise tolerance specifications.

Ensuring vehicles’ dependability hinges on using CNC machines to create top-notch transmission components that align with stringent quality standards.

Suspension Components

Control arms and steering knuckles, integral to vehicle suspension systems, are produced using CNC machining to guarantee robustness and exacting specifications. The meticulous crafting of these parts is pivotal in boosting the stability and safety of vehicles, underlining their significance in elevating overall driving performance.

The increased accuracy offered by CNC machining solidifies its essential position within automotive manufacturing processes, directly impacting the improvement of vehicle stability and safety.

Types of CNC Machines in Automotive Manufacturing

In the realm of automotive manufacturing, a diverse array of CNC machines is employed for specialized tasks. Notable varieties include CNC milling machines, CNC lathes, and CNC plasma cutters among other types. These apparatuses are instrumental in the precise fabrication of complex parts, markedly enhancing production capabilities within the automotive industry.

Employing a rotational cutting action to produce symmetrical components, CNC lathes are essential tools. Conversely, CNC milling machines provide the versatility needed to craft intricate details with high precision. For shaping and slicing metal sheets necessary for vehicle body panels and other external features effectively, there’s a reliance on CNC plasma cutters.

Thanks to their programmability feature, these machine tools facilitate swift changes across different projects thus greatly reducing production timeframes. The prerequisites that dictate their design include exceptional accuracy as well as flexibility, qualities paramount in meeting varied manufacturing demands efficiently.

CNC Milling Machines

In the realm of automotive manufacturing, CNC milling machines are indispensable for their capacity to execute with high precision and adaptability, enabling the production of complex parts integral to contemporary vehicle design. This complexity plays a significant role in influencing both vehicular dynamics and safety standards.

Manufacturing essential items like control arms, tie rods, ball joints, steering knuckles, and wheel hubs is made possible by the exacting capabilities of CNC milling machines. Their proficiency in crafting detailed shapes and specific features elevates the performance criteria and aesthetic appeal of automotive components.

CNC Lathes

CNC lathes are highly adept at fabricating cylindrical automotive components such as axles and drive shafts, thanks to their exceptional capability in creating parts that require high precision.

The capacity of CNC lathes to manufacture cylindrical automotive parts within strict tolerances is crucial for guaranteeing the longevity and functionality of these automotive elements.

CNC Plasma Cutters

CNC plasma cutters are instrumental in shaping metal sheets, which is a critical step in creating body panels within the automotive manufacturing sector. These devices excel at slicing through dense materials, thus making them perfectly suited for fabricating vehicle body panels and various other external components.

The use of CNC plasma cutters to slice and mold metal sheets considerably improves the production workflow in automotive manufacturing due to their efficiency.

Advantages of CNC Machining in Automotive Manufacturing

CNC machining has significantly transformed the process of automotive manufacturing, offering notable benefits such as enhanced precision, accelerated production speeds, and tailored customization options. This advanced technology enables the production of complex and high-quality components with reduced material waste, establishing its essential role in CNC machining within the automotive industry.

The adoption of automation and robotics within these machining processes has Augmented efficiency while diminishing the reliance on manual labor. Enterprises like LKprototype have become specialists in providing custom CNC machining services for vehicle parts, delivering rapid prototyping alongside small to medium volume manufacturing that guarantees swift turnaround times without compromising quality standards.

Boasting a selection of over 65 certified materials suited for CNC prototypes, LKprototype offers multifaceted production capabilities designed to meet the dynamic demands faced by those in the automotive sector.

Precision and Accuracy

CNC machining is the method of choice for fabricating components that necessitate exacting precision and adherence to strict tolerances. The creation of critical engine parts such as crankshafts and camshafts demands extraordinary accuracy, which is pivotal for ensuring both performance and safety. The utilization of advanced materials in CNC machining contributes to greater precision by diminishing thermal expansion and wear, thereby promoting stability throughout the production process.

Particularly proficient at crafting complex designs with precise dimensions, CNC milling machines excel in producing automotive parts within narrow tolerance ranges—the standard achievable tolerances are around 0.001 inches. Firms like LKprototype have demonstrated their expertise in high-precision manufacturing by offering cnc machining services capable of achieving ultra-tight tolerances up to +/- 0.0002 inches through meticulous precision machining processes including cnc milling.

Speed and Efficiency

CNC machining outpaces traditional machining methods in speed, greatly boosting the pace and efficiency of production. The automated characteristics of CNC machines enable swift prototyping and fast delivery during low-volume runs, resulting in notably shortened lead times.

Artificial intelligence (AI) incorporated into CNC machining refines processes, thereby elevating production efficacy while minimizing idle periods. Predictive algorithms from machine learning assess tool degradation to lower downtime and extend the lifespan of tools.

Contemporary CNC machinery is engineered to consume less energy, which not only augments manufacturing effectiveness but also harmonizes with eco-friendly manufacturing protocols.

Customization and Flexibility

CNC machining offers a high level of adaptability in the realm of automotive manufacturing, as it allows for swift modifications to component designs without incurring significant costs associated with tooling adjustments. This process is essential for customizing parts that meet exact specifications and various client requirements with notable precision.

The versatility of CNC machines enables them to handle an array of materials such as metals, plastics, and composites. This versatility broadens their customization capabilities by facilitating the fabrication of diverse components ranging from basic shapes to highly intricate geometries. The integration of CNC machining with additive manufacturing processes unlocks possibilities for producing complex designs not possible through conventional methods, thus supporting cutting-edge vehicle design and expedited prototype development.

This combination results in uniquely tailored parts that effectively cater to precise customer preferences while optimizing functionality.

Advanced Technologies Enhancing CNC Machining

New technologies are having a profound effect on the performance and capabilities of CNC machining operations within the automotive industry. The integration of sophisticated material management systems, automation, artificial intelligence (AI), Internet of Things (IoT), and additive manufacturing into CNC machining is improving its efficacy while elevating the accuracy with which automotive components are produced.

Such advancements facilitate more efficient manipulation of advanced materials and composites, resulting in improved lightweighting approaches and heightened overall operational efficiency.

Integration with AI and Machine Learning

Incorporating artificial intelligence and machine learning into CNC machining transforms the field by reducing idle times, boosting both effectiveness and uniformity in products. The use of AI provides automated recommendations that improve precision in machining operations as well as optimizing pathways for cutting tools.

Efficiency and consistency of products are enhanced through dynamic optimization of tool paths along with automated checks on quality. This ensures that outputs maintain a high standard of quality. In essence, CNC machining greatly benefits from advancements in operational efficiency and accuracy thanks to AI and machine learning technologies.

IoT and Smart Manufacturing

The Internet of Things (IoT) is essential for enhancing performance and maintenance in CNC machining, as it allows manufacturers to track the real-time functioning of CNC machines. This monitoring ensures that the machines are performing efficiently and helps avoid unforeseen interruptions by employing predictive maintenance.

Incorporating IoT into machining processes involving CNC results in notable improvements in efficiency, accuracy, and general operational excellence. Consequently, IoT has become an indispensable element within the realm of intelligent manufacturing associated with CNC machining.

Additive Manufacturing Synergies

Advanced materials and complex part geometries can be realized through additive manufacturing, which enhances CNC machining processes. This integration facilitates the creation of elaborate designs and novel components not possible with conventional techniques, thus accelerating rapid prototyping and bespoke production.

The fusion of these technologies significantly augments automotive manufacturing capacities by enabling the fabrication of customized, high-quality automotive parts.

Sustainable Practices in CNC Machining

CNC machining contributes to sustainable manufacturing by enhancing the utilization of materials and minimizing waste production. This method can substantially decrease the ecological impact of manufacturing processes due to its capabilities in material conservation, reduction in energy consumption, and adherence to recycling protocols.

Through efficient use of resources combined with energy conservation, CNC machining demonstrates its compatibility with eco-friendly manufacturing practices. The adoption of sophisticated approaches aimed at responsible resource management allows CNC machining to play a vital role in promoting environmental sustainability within the realm of automotive production.

Material Efficiency

CNC technology enables the execution of precise cuts, which helps to reduce unnecessary removal of material, thus optimizing its usage and decreasing waste. The utilization of precision CNC machining techniques also allows for a reduction in material needed, Cutting down on waste while boosting production efficiency.

Such methods not only promote sustainable manufacturing practices, but also ensure that resources are employed in an effective manner, consistent with objectives aimed at eco-friendly manufacturing.

Energy Savings

Contemporary CNC machines are engineered to function with reduced energy usage, thereby considerably diminishing the carbon footprint associated with manufacturing. Features like automatic shut-off during idle times in these machines contribute to decreased energy consumption while still ensuring they operate at a high level of efficiency.

The combination of energy efficiency and precise performance in CNC machining aids in fostering sustainable production practices. This is particularly beneficial for the crafting of superior automotive components, as it lessens their environmental impact without compromising on quality.

Recycling and Circular Economy

CNC machining is instrumental in enhancing the adoption of recycled materials for producing automotive parts, bolstering the circular economy. The introduction of recycling initiatives within CNC machining operations allows for the reclamation of precious resources, fostering a sustainable manufacturing methodology.

The promotion by CNC machining to incorporate recycled substances into production processes and establish closed-loop systems fosters a circular economic model. This approach diminishes waste output and advocates for ecological preservation.

Quality Control Measures in Automotive CNC Machining

To guarantee the creation of precise and reliable parts in automotive CNC machining, it is vital to adhere to strict quality assurance measures. Regular calibration and servicing are imperative for sustaining the high level of precision necessary to fulfill the stringent tolerances demanded by automotive manufacturing processes.

Quality is consistently assessed at multiple stages during production through in-process inspections that track dimensions and adherence to specified tolerances immediately, ensuring uniformity across components. Non-Destructive Testing (NDT) techniques like ultrasonic testing are employed as well, which aid in discovering any concealed flaws within machined components, confirming they conform with set criteria for accuracy and structural integrity.

Leveraging IoT technology enables ongoing surveillance of machine performance, which facilitates prompt detection and correction of problems. Simultaneously, artificial intelligence systems assess machinery data on-the-fly so as to forecast when maintenance should occur thereby reducing chances of unforeseen malfunctions.

Lastly, educating staff plays a pivotal role in maintaining effective control over quality. This makes sure operators possess the required expertise not just execute inspection protocols, but also uphold rigorous standards associated with high-precision tasks characteristic of automotive CNC operations.

Comparing CNC Machining with Other Production Methods

In the assessment of CNC machining relative to alternative manufacturing techniques such as injection molding, considerations like expense, caliber, and rate of production are essential. Injection molding is adept at quickly turning out large quantities of identical items. For fabricating components with intricate designs that must adhere to stringent quality standards, CNC machining proves more adaptable.

Though starting expenses can be more substantial for CNC machinery, they can be more substantial. To other methods, it ultimately becomes a cost-efficient solution due to its proficiency in crafting an array of automotive parts—from engine blocks to transmission components—with exceptional accuracy and dependability. The capability and exactitude inherent in CNC machining establish it as the method of choice for creating complex and superior-grade automotive elements.

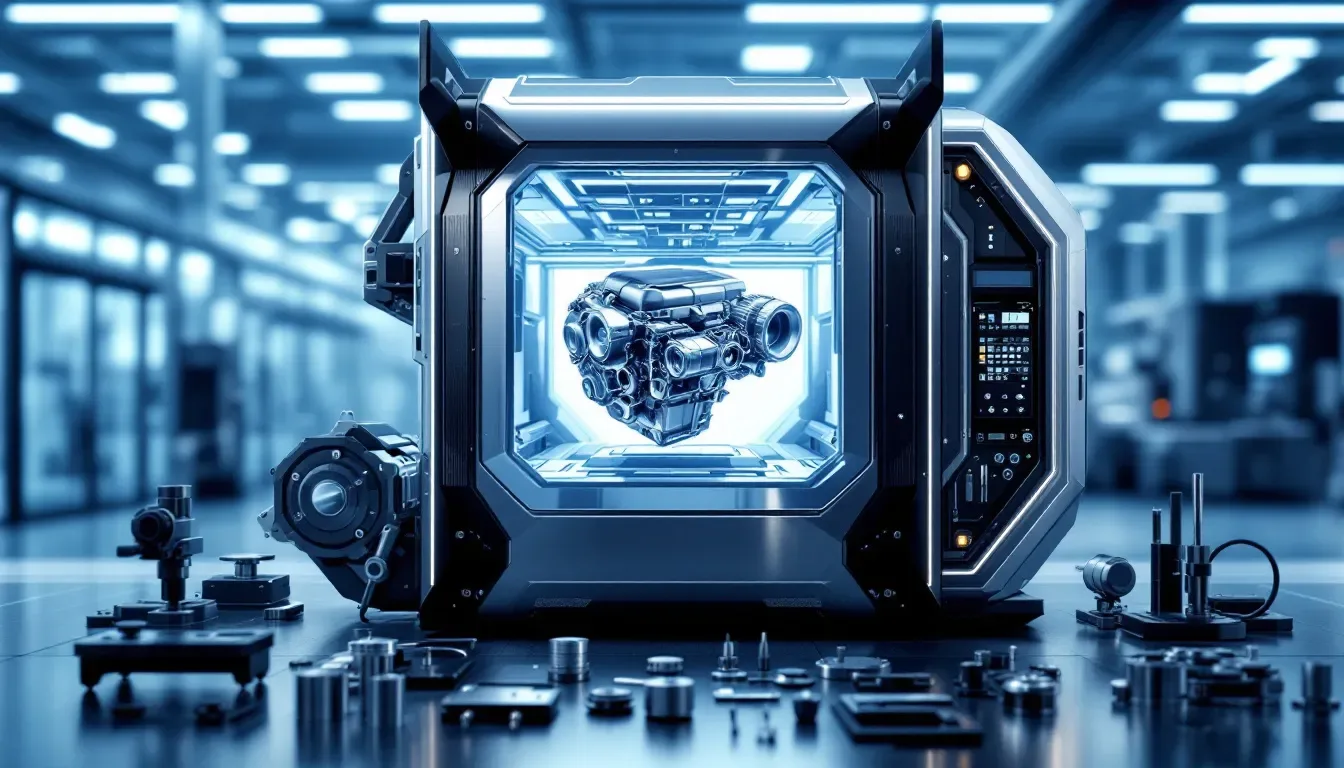

Applications of CNC Machining in Electric Vehicles

CNC machining is vital in the production of superior battery housings crafted from light materials, a crucial aspect for electric vehicles. It enables the construction of intricate geometries required for parts like cooling plates within these vehicles, which are essential for peak operation and energy efficiency.

This technique supports rapid alterations to component designs, granting manufacturers the ability to quickly respond to shifting market demands and push forward with innovation in the swiftly progressing field of electric vehicles. CNC machining’s exactitude and adaptability render it an indispensable asset in crafting components for electric cars, aiding in forging more effective and dependable transport solutions powered by electricity.

LKprototype: Your Partner in Automotive CNC Machining

Since its inception in 2009, LKprototype has established itself as a reliable ally to the automotive sector by concentrating on exceptional production skills across diverse areas. The company excels at providing tailor-made prototyping and parts fabrication services for automobiles, playing an integral part in developing automotive products through the creation of both prototype and full-scale production components. It boasts ISO 9001 certification while its suppliers achieve several industry recognitions including IATF16949 and ISO 14001 certifications, guaranteeing top-tier quality for all their outputs.

With expertise in quick-turnaround prototyping, LKprototype can deliver CNC machined items within an expedited timeframe of just two days under specified conditions. Offering access to over 65 certified materials suited for CNC prototypes ensures that they adapt swiftly to meet the changing demands inherent within the automotive industry.

LKprototype Serves automobile manufacturers by offering sophisticated surface finishing techniques that improve both function and aesthetics of auto parts. By utilizing cutting-edge manufacturing technology alongside proficient engineers, LKprototype guarantees swift shipping times without compromising rigorous quality control measures.

Summary

The prospects for automotive CNC machining are highly promising as technological advancements continue to augment its precision, rapidity, and tailorability. This process is crucial in crafting superior-grade automotive components ranging from motor parts to suspension elements, pivotal for maintaining vehicle performance and safety standards. The incorporation of technologies such as AI, the Internet of Things (IoT), and additive manufacturing elevates CNC machining’s indispensability within the realm of automobile production. Moving forward with an eco-conscious approach, CNC machining aligns seamlessly with sustainable manufacturing initiatives by optimizing material consumption and curtailing waste generation. Enterprises like LKprototype demonstrate the immense potential that lies within CNC technology through their offerings of swift prototyping services alongside high-caliber production solutions tailored to meet the progressive demands of the automotive industry. Thus, a new era has dawned on automotive fabrication — one energized by the unparalleled precision and productivity inherent in modern-day CNC machinery processes.

Frequently Asked Questions

What types of parts does LKprototype produce for the automotive industry?

LKprototype manufactures a range of parts, including both prototype and production components for the automotive industry. This versatility helps meet various automotive needs effectively.

What is the significance of design validation and testing?

Ensuring that a product fulfills its intended purpose, aesthetics, and performance criteria is essential, and design validation along with testing plays a key role in this. By identifying and correcting possible problems through this process, the end result is an enhanced final product that is both reliable and efficient.

What services does LKprototype offer?

LKprototype specializes in custom automotive prototyping and parts manufacturing, facilitating the development of automotive products. Their services are tailored to meet the specific needs of the automotive industry.

What certifications does LKprototype hold?

LKprototype is ISO 9001 certified, and their suppliers hold several industrial certifications, such as IATF 16949 and ISO 14001.

How quickly can LKprototype deliver CNC parts?

LKprototype can deliver CNC parts in as fast as 2 days. This rapid turnaround time ensures you receive your components promptly.

LKprototype

LKprototype