Share a little biographical information to fill out your profile. This may be shown publicly.

Wondering how to fabricate plastic parts? This guide covers the essentials from material selection to manufacturing techniques. Learn how to choose the right plastic, design your parts, and pick the best fabrication methods suited for your needs. Key Takeaways Understanding various types of plastic materials is crucial for selecting the appropriate resin that meets functional and budgetary requirements in manufacturing. Designing plastic parts necessitates careful planning and the use of specialized tools to ensure structural integrity and efficient manufacturing processes. Choosing the right manufacturing technique, such as injection molding or extrusion, significantly influences the quality and cost-effectiveness of plastic products.…

Need to prototype a product without breaking the bank? This article covers the key steps and methods on how to prototype a product, guiding you from an idea to a functional prototype. Learn about defining your product, creating sketches, building physical models, and refining your design. Discover cost-effective techniques and avoid common pitfalls to ensure your prototype meets user needs. Key Takeaways Prototyping transforms ideas into tangible models, allowing for early evaluation and informed decision-making to save time and costs. Engaging users during the prototyping phase provides critical feedback, helping to refine designs and ensure the final product meets user…

Wondering what makes up a cnc machine part? This guide will introduce you to the core components, their functions, and why they are critical for precision and efficiency in manufacturing. Key Takeaways CNC machines automate precise machining tasks, ensuring high accuracy and efficiency across various industries such as aerospace and automotive. Key components of CNC machines, including the Machine Control Unit, driving system, and feedback system, work together to maintain precision and reliability during operations. Regular maintenance and timely upgrades of CNC machine parts are critical for enhancing performance, prolonging lifespan, and preventing operational failures. Understanding CNC Machines Understanding CNC…

Rapid prototyping services quickly turn your ideas into functional prototypes using advanced technologies. This article covers the materials and techniques involved, getting instant quotes, and the key benefits you can expect. Urethane casting Key Takeaways Rapid prototyping utilizes diverse materials and techniques, such as CNC machining and additive manufacturing, to create functional prototypes similar to final products. Instant quoting technology allows businesses to receive real-time pricing and analysis by uploading 3D CAD files, enhancing decision-making and reducing lead times. Quality assurance processes, including design verification and meticulous inspections, are crucial for maintaining high standards in rapid prototyping and preventing issues…

If you’re involved in plastic injection moulding, you know that choosing the right raw materials is crucial. Different raw materials offer various properties, affecting the performance, cost, and applications of the final product. This article will guide you through the most commonly used plastic injection moulding raw materials, their unique attributes, and how to select the best material for your needs. Key Takeaways Successful plastic injection molding relies on selecting suitable raw materials, which must meet specific performance, durability, and cost criteria. Commonly used materials such as polyethylene, polypropylene, and ABS each have unique properties catering to diverse applications across…

Cast metal parts are essential components created by pouring molten metal into a mold, allowing it to solidify into a desired shape. This versatile manufacturing process is vital for producing complex and durable parts used in industries ranging from automotive to aerospace. In this article, we will explore the techniques and applications of cast metal parts, offering insights into their advantages and the various methods involved in their production. Key Takeaways Metal casting involves pouring molten metal into a mold to create durable, intricate parts and is widely used across various industries, including automotive, aerospace, and medical. The metal casting…

Wondering how to make a mold for silicone parts? This guide breaks down the process into simple steps. Learn how to pick the right silicone, gather your tools, design your mold, and go through the mixing, curing, and demolding phases. Get ready to create your own professional-grade silicone molds. Key Takeaways Select the appropriate silicone type (tin-cure for beginners and platinum-cure for high durability) based on project needs for successful mold making. Essential tools, materials, and a well-designed mold box are critical for creating precise and effective silicone molds. Proper mixing, curing, and maintenance techniques significantly enhance the quality and…

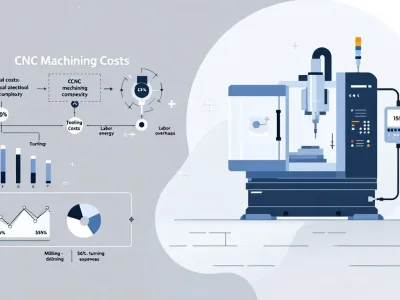

Are you looking to achieve low cost CNC machining without sacrificing quality? This guide offers valuable insights into reducing CNC machining expenses. You’ll learn about factors that impact costs, tips for cutting down expenses, and affordable CNC machine options for small businesses. Dive in to discover strategies that can optimize your CNC machining processes efficiently. Key Takeaways CNC machining costs are influenced by material selection, design complexity, machine setup time, and production volume. Key strategies to reduce CNC machining costs include optimizing material usage, simplifying designs, bulk ordering, and minimizing finishing operations. Low-cost CNC machining provides significant advantages like cost…

Die casting vs injection moulding: which is right for your project? This article breaks down the key differences in materials, precision, and production volumes. These insights will guide you in making the best choice. Key Takeaways Die casting is a high-pressure metal casting process. It is ideal for producing intricate parts with excellent dimensional accuracy. This method mainly uses nonferrous metals like aluminum and zinc. Injection moulding is a versatile plastic manufacturing method. It allows for rapid production of complex shapes but has higher initial tooling costs. It also has limited design flexibility. When selecting between die casting and injection…

CNC machining 1. Introduction to CNC Machining Services What are CNC machining services? Precision engineering in CNC machining services, also known as precision machining, involves the use of computer-controlled machines to manufacture parts with high precision and accuracy. CNC machining processes are crucial in achieving precise manufacturing standards and certifications, highlighting operational advantages such as high accuracy and the ability to efficiently produce custom parts. These services are widely used across various industries due to their ability to produce complex and intricate designs. The cnc machining advantages include high accuracy, repeatability, and capability for continuous operation, making it ideal for…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.