Share a little biographical information to fill out your profile. This may be shown publicly.

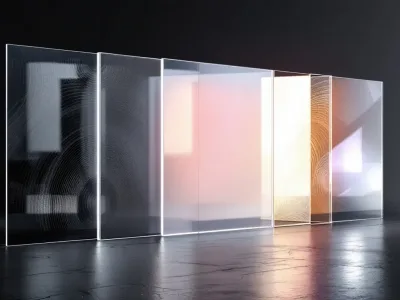

Acrylic CNC machining uses computer-controlled devices to accurately cut and shape acrylic materials. It provides precision, reduces material waste, and speeds up production compared to manual methods. In this article, you’ll learn about the advantages, key properties, and best practices for achieving high-quality results in acrylic CNC machining. Key Takeaways CNC machining offers high precision and speed for acrylic, significantly reducing material waste and production costs, making it an efficient manufacturing method. Key properties of acrylic, including its transparency, impact resistance, and lightweight nature, contribute to its widespread use in industries such as automotive, medical, and construction. Implementing best practices…

Wondering whether MIG and stick welding is right for your needs? This article breaks down the key differences, pros, and cons of each welding method. Key Takeaways MIG welding offers faster and cleaner welds with a continuous wire feed but is less effective outdoors and for thick metals. Stick welding is versatile and strong on dirty surfaces, excelling in thicker materials, but operates slower and requires more skill. Choosing between MIG and stick welding involves considering project requirements, material types, and environmental factors. Understanding MIG Welding MIG welding, commonly referred to as Metal Inert Gas welding, involves the use of…

The melting temperature of copper, specifically what’s the melting temperature of copper, is 1085°C (1984°F). Understanding this specific melting point is crucial for various industrial applications, including casting and welding. In this article, we will explore not just the melting point of pure copper, but also how alloying elements and environmental factors can influence this property. Key Takeaways The melting temperature of pure copper is 1085°C (1984°F), making it suitable for high-temperature applications without loss of structural integrity. Copper alloys exhibit varying melting points, influenced by their composition, with examples like bronze melting between 850°C to 1000°C, and beryllium copper…

This guide will explore the most common CNC machining types and their applications in precision manufacturing. Key Takeaways CNC machining encompasses various machine types, including milling, lathes, and laser cutters, each suited for specific manufacturing processes and industries. The selection of the appropriate CNC machine depends on factors such as material type, part complexity, and required precision, crucial for optimizing manufacturing efficiency. CNC machining provides significant advantages like precision and uniformity, but it also poses challenges such as higher costs and system complexity, necessitating proper training for effective operation. CNC Milling Machines CNC machines, specifically CNC milling machines, are pivotal…

CNC machinists are essential in manufacturing and operating CNC machines to produce precision parts. This article explains the key CNC machinist duties and the skills needed for the job. Key Takeaways CNC machinists operate, program, and maintain CNC machines to produce precise metal or plastic parts, requiring a blend of technical expertise and hands-on skills. Effective communication and collaboration with engineers and designers are essential for CNC machinists to ensure project specifications and enhance production efficiency. Continuous learning and obtaining certifications are important for career advancement in CNC machining, as they help machinists stay competitive and adapt to technological advancements.…

CNC machinists operate computer-controlled machines to produce precision parts and components. This crucial role involves programming and maintaining equipment to meet detailed design specifications. As technology advances, the demand for skilled CNC machinists is rising, making this a promising career path. This article will outline the duties of the CNC machinist, required skills, and career opportunities. Key Takeaways CNC machinists are essential in modern manufacturing, requiring a mix of technical skills, attention to detail, and strong problem-solving abilities to ensure precision in high-quality component production. The career path for CNC machinists is promising, offering opportunities for advancement into specialized roles,…

Understanding the right CNC file format is crucial for precision machining. Key formats like G-code, STEP, and DXF ensure your CNC projects run smoothly and accurately. This article will guide you through these essential formats and their roles in CNC machining. Key Takeaways The essential CNC file formats for precision machining include G-code, STEP, and DXF, each serving unique roles in maintaining accuracy and compatibility. Conversion of CAD files into CNC-compatible formats through CAM software is crucial for precise machining instructions and reduces the risk of errors. Effective communication with CNC technicians and detailed preparation of CAD files are vital…

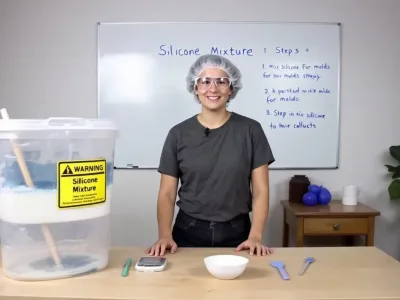

Looking to learn how to make silicone for molds at home? This guide will walk you through the necessary steps and materials, ensuring you can create high-quality molds easily. Key Takeaways Making silicone molds at home is cost-effective and allows for customization in crafting projects. Key materials for DIY silicone molds include silicone caulking, cornstarch, and mold release agents to ensure easy demolding. Curing time for molds varies, and safety precautions, like wearing gloves and ensuring good ventilation, are crucial during the process. Why Make Silicone Molds? Manufacturing silicone molds yourself can lead to significant savings over purchasing off-the-shelf options.…

Plastic weld adhesives create strong bonds between plastic materials by chemically fusing them. This article explains how they work, reviews the best options, and provides usage tips. Key Takeaways Plastic weld adhesives create strong molecular bonds between plastics, making them ideal for durable repairs on various thermoplastics like PVC and acrylic. The effectiveness of these adhesives relies on proper surface preparation, capillary action, and quick setting times, often curing within minutes. Safety precautions, including protective eyewear and ventilation, are essential when using plastic weld adhesives to prevent injuries and ensure a safe working environment. Understanding Plastic Weld Adhesives Adhesives known…

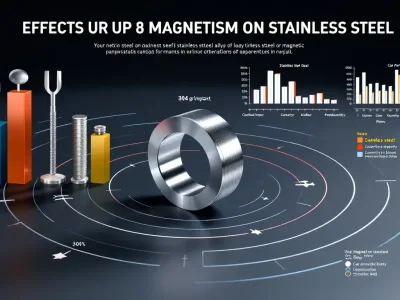

Is stainless magnetic? It can be, but it depends on the type. In this article, you’ll learn why some stainless steels are magnetic and others aren’t, and how this affects their uses. Key Takeaways Stainless steel’s magnetic properties are influenced by its crystal structure and chemical composition, with martensitic and ferritic types being magnetic, while austenitic types are typically non-magnetic. Understanding the magnetic characteristics of different stainless steel types—like austenitic, ferritic, martensitic, and duplex—is crucial for selecting the right material for specific applications such as manufacturing and food processing. Testing for magnetism using a simple magnet can indicate magnetic properties,…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.