Looking to achieve high precision in a small workspace? A 5 axis desktop CNC machine provides advanced capabilities needed for complex designs. They are perfect for industries like aerospace, medical devices, and jewelry. In this article, we review the top 5-axis desktop CNC machines available today.

Key Takeaways

5-axis desktop CNC machines offer advanced machining capabilities from multiple angles, maintaining high precision suitable for various industries such as aerospace and medical device manufacturing.

Compact designs of these machines significantly save floor space while delivering high performance, making them ideal for workshops with limited space.

With integrated software solutions and user-friendly interfaces, 5-axis CNC machines facilitate rapid prototyping and ease of use for both beginners and experienced users.

Cutting-Edge 5-Axis Desktop CNC Machines

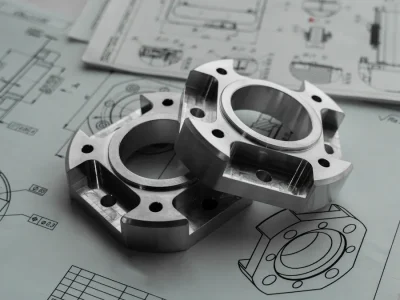

5-axis CNC milling machines are at the cutting edge of current machining advances. These devices showcase exceptional engineering, enabling intricate and advanced machining from numerous perspectives, which revolutionizes the creation of complex shapes previously deemed unattainable. Thanks to their ability to operate in multiple directions, 5-axis CNC milling machines deliver high accuracy and can fulfill demanding tolerances during production processes. This level of precision renders them crucial within industries where such exactitude is essential.

Consider the aerospace sector as an example. It frequently employs miniature 5-axis CNC machines for fabricating intricate components like turbine blades and engine parts that need to be both lightweight and aerodynamic. The unparalleled precision afforded by 5-axis CNC technology ensures these parts adhere to strict standards required by this industry. Their use extends beyond aerospace into other fields such as medical device manufacturing, automotive part assembly, and even elaborate jewelry crafting due to their versatile capabilities.

The capacity of these machines for multi-angle component machining without necessitating repositioning of the workpiece introduces significant time savings while minimizing potential errors—a key factor contributing to why they’re increasingly becoming a mainstay in modern production environments where mastering control over y axis and z axis operations is pivotal for maintaining precise results.

These sophisticated units equip users with dependable tools suitable not only for metal but also for plastic or wood materials—guaranteeing detailed execution that brings your design visions effectively into reality regardless of the chosen material.

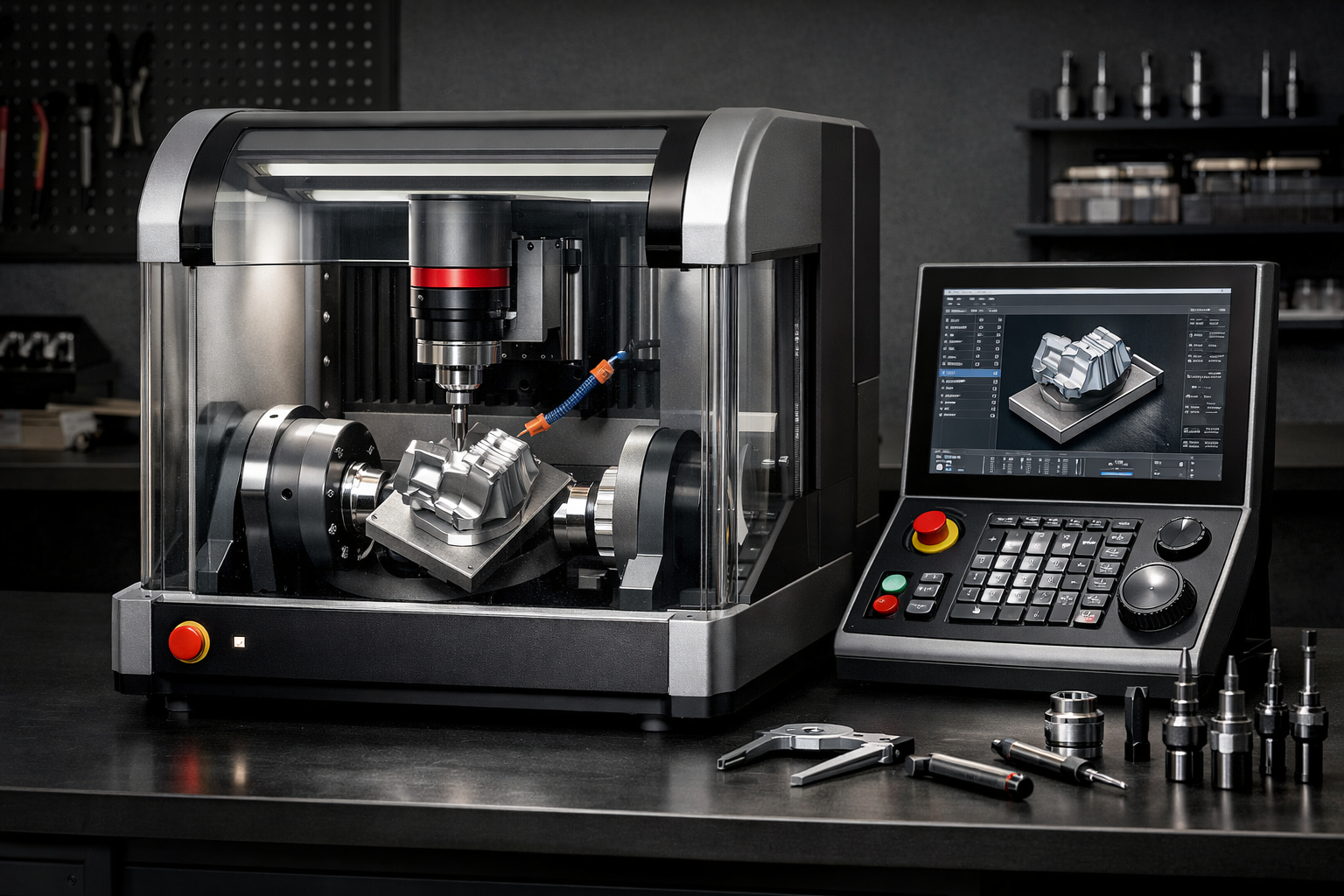

Compact Design with High Precision

The modern 5-axis CNC desktop machines stand out with their space-efficient design. These devices are crafted to reduce the required floor space by approximately 50% when compared to conventional models, which is particularly beneficial for workshops where space is at a premium. Yet, despite their compact size, these machines deliver impressive performance and precision.

Consider the TT120 model as an example. This machine tips the scales at merely 60 kilograms, offering both portability and strength. Its Solid Mono-Block Cast Body provides outstanding stability that’s essential for sustaining high levels of precision during machining tasks. Its electronic tool setting attribute achieves repeatability within one millimeter, ensuring consistently precise cuts regardless of how complex the design may be.

These diminutive yet accurate devices prove exceptionally useful in sectors where conserving space without compromising accuracy is vital — such as in medical device production and jewelry crafting industries. Their capability to fabricate small-scale parts with detailed perfection makes them indispensable assets within these domains.

For both professionals and enthusiasts alike who seek a blend of compactness and meticulous precision in machinery, these desktop CNC systems present themselves as invaluable additions to any workspace setup.

Advanced Control Systems

At the core of every CNC milling machine lies its control system, with modern 5-axis CNC milling machines no different. These sophisticated machines are equipped with Raspberry-based embedded control systems that deliver high-efficiency operations and allow for precision machining at spindle speeds of up to 40,000 RPM. The versatility of these control systems is Bolstered by their ability to support a variety of CNC programming languages in line with industry standards, ensuring they work seamlessly with an extensive array of software.

A standout feature for ease-of-use is the touchscreen interface integrated within these machines. An example such as the TT120 exemplifies this user-centric design through its intelligent interface complete with a touch-controlled tablet, which simplifies interaction and enhances user-friendliness.

Enhancing their capabilities are features like closed-loop feedback mechanisms which significantly boost accuracy while executing intricate machining tasks. Automatic tool changers also form part of these advanced setups, minimizing hands-on involvement and accelerating production cycles. Together, these state-of-the-art computerized controls guarantee superior handling even during complex machining processes requiring exceptional precision.

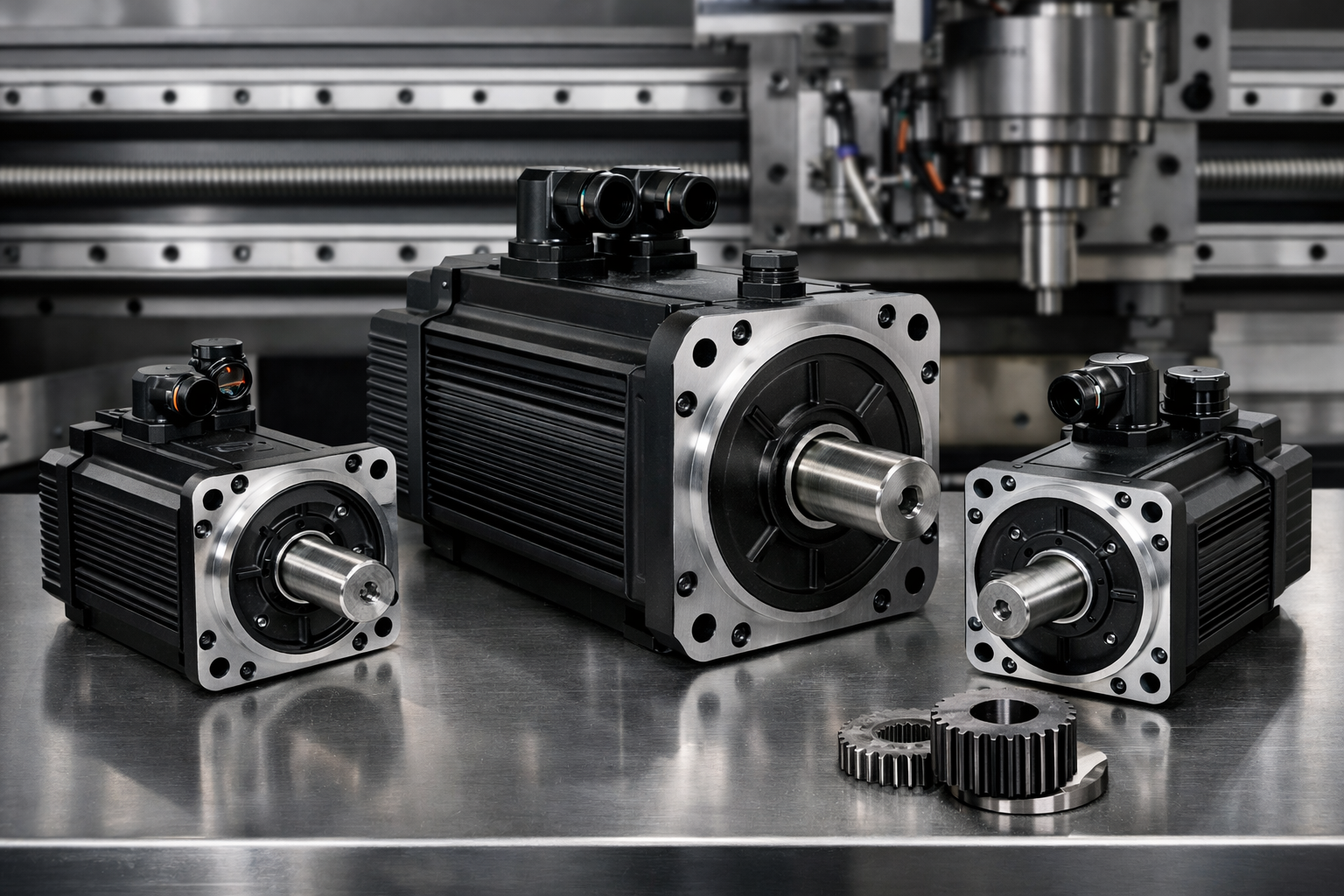

High Torque and Power Efficiency

Servo motors that deliver high torque are essential for the efficient operation of CNC machines. Desktop 5-axis CNC machines come equipped with NEMA23 stepper motors and provide options for either closed-loop steppers or DC servo motors to furnish the substantial torque required for precise milling processes. This feature enables the machines to proficiently work with diverse materials, spanning from pliable plastics to sturdy metals.

The system architecture of these machines is crafted for heightened dynamic performance, incorporating output that adapts velocity dependent on the path taken, thereby optimizing power control and boosting efficiency. With an electrical configuration designed around a 220V input and delivering a 36V 20A output, these devices sustain consistent reliable functioning across various material types, which improves their operational productivity.

For CNC machinery necessitating outstanding cutting performance and accuracy, high torque motors prove indispensable. These powerful components ensure users can achieve excellent results whether they’re sculpting complex designs in wood or fabricating durable parts out of metal, all thanks to the potent combination of forceful energy conversion and precision offered by such equipment.

Versatile Material Compatibility

5-axis CNC machines stand out for their impressive ability to process a multitude of materials, which renders them indispensable across multiple sectors including aerospace and consumer electronics. They adeptly manage an array of metals such as aluminum, copper, titanium, along with several types of plastics. The extensive range of material options they accommodate leads to heightened manufacturing and prototyping adaptability.

For instance, LKprototype showcases its capability by offering in excess of 65 certified substances suitable for CNC machining that encompass frequently used materials like aluminum and copper as well as ABS plastic and nylon among others. Plastics like ABS and nylon are often selected due to their excellent ease-of-machining qualities coupled with applicational flexibility. For instances demanding superior mechanical endurance and thermal resistance within the realm of CNC machining engineering plastics such as PEEK or polycarbonate are the go-to choices.

Besides fabricating components directly, 5-axis CNC machines play a pivotal role in mold production. Their capacity to carve complex molds featuring intricate contours is invaluable for industry areas including but not limited to injection molding and die casting processes. Such wide-ranging accommodation regarding material compatibility guarantees these machines can effectively fulfill distinct industrial requirements presenting themselves as significant assets in any workshop environment.

Integrated Software Solutions

Software integrations significantly enhance the capabilities of 5-axis CNC desktop machines. By facilitating intricate designs and complex procedures, these software tools extend beyond the limits set by conventional machining techniques. Notably, CAM software translates CAD models into G-code instructions that are then executed by the machine to carry out precise machining tasks.

Some 5-axis machines come equipped with simulation software that allows for a preview of the entire machining process prior to its commencement, thereby minimizing mistakes and guaranteeing superior outcomes. To maintain peak performance and expand their functional range, it is vital to regularly update this machinery’s accompanying software.

With such integrated solutions in place, 5-axis CNC machines stand as an exemplary choice for enterprises aiming to excel and remain competitive within the manufacturing sector.

Rapid Prototyping and Production

In the current dynamic landscape of manufacturing, possessing the capacity to transition seamlessly from design to production confers a notable competitive edge. Desktop CNC machines with 5-axis functionality expedite prototype development, empowering creators to swiftly generate working models that boast complex shapes. This proficiency dramatically compresses product development cycles and facilitates swift iterations and refinements in design.

The simultaneous machining abilities of these devices diminish both the duration required for production processes and potential setup inaccuracies. Their high-efficiency rates combined with brisk feed speeds considerably enhance overall productivity levels.

Typically, CNC machining tasks can be finalized within a timeframe of 5 business days. Simpler components may even be ready in just one day. For small-scale batch manufacturing scenarios, this quick-turnaround prototyping is exceptionally advantageous—enabling cost-effective validation of prototypes while also hastening project timelines significantly.

User-Friendly Features

5-axis CNC machines are equipped with user-friendly characteristics that cater to both novice and seasoned operators in the field of machining. These devices typically feature a graphical interface designed for use on Microsoft Windows platforms, which simplifies interaction and enhances usability. For instance, the TT120 model boasts an intuitive interface similar to that of a 3D printer, making it straightforward for users.

Institutions focused on education frequently utilize these versatile 5-axis CNC machines to offer learners hands-on training in sophisticated machining practices as well as instruction in CAD/CAM software programming. To aid newcomers in mastering machine functionality, certain models come equipped with integrated tutorials and modes specifically designed for training purposes.

With such features aimed at ease-of-use combined with educational resources built into their design, these tools provide adaptability and can be leveraged by a broad spectrum of individuals from hobbyists all the way through to industry experts.

Reliable Performance and Maintenance

Ensuring the longevity and uniform functionality of 5-axis CNC machines hinges on their reliable performance and straightforward upkeep. These sophisticated machines boast positioning precision to within 0.10 micrometers, ideal for tasks requiring high accuracy. They are enhanced with features such as automatic workpiece recognition and adjustments to Z-height, which elevate the precision of operations.

To guarantee smooth operation, these machines necessitate regular maintenance. To preserve their exactitude and circumvent errors during machining, frequent calibration is indispensable. The application of lubricant to components in motion is also vital to prevent deterioration and sustain precision over time.

These high-torque CNC machines come equipped with internal cooling systems that circulate fluid, enabling them to operate consistently for protracted periods without overheating. By adhering to these maintenance protocols diligently, users can ensure that their machinery maintains dependable performance throughout its service life.

Shipping and Delivery Information

When investing in a 5-axis desktop CNC machine, it’s critical to pay attention to the particulars of shipping and receipt. The estimated delivery period for the TT120 model spans between 5-7 working days. Customers residing within the EU need to be cognizant of local VAT charges that will come into effect at customs, while those from the UK should expect an inclusive VAT charge of 20% in their purchase price.

For international shipments beyond UK borders, opting for ‘Delivered at Place (DAP) Uncleared’ implies that recipients are responsible for covering any locally applicable duties and taxes. Transporting a CNC machine customarily necessitates utilizing sturdy trucks or trailers tailor-made for handling such robust machinery—48-foot flatbeds are typically employed when conveying these machines.

In some instances, large machines may require disassembly before being shipped to ensure they can be transported safely. This process demands skilled professionals who can manage both disassembly and assembly effectively upon delivery. Taking these elements into account is crucial in guaranteeing an untroubled shipping experience with minimal complications.

Payment Options and Purchase Process

It is essential to comprehend the various payment methods and the steps involved in acquiring a 5-axis CNC machine. The cost for acquiring a TT120 5-Axis CNC Machine stands at £10,280.00. For Details or to initiate the acquisition, customers may utilize the online shop offered by the provider.

It’s crucial to account for ancillary expenses like taxes that are due when completing your purchase. A thorough grasp of these aspects facilitates an efficient purchasing experience and guarantees a seamless financial transaction.

Summary

To summarize, the 5-axis desktop CNC machine stands out as an exemplary device that merges a space-saving design with exceptional accuracy and multifaceted functionality. These machines come fully equipped with state-of-the-art control systems, motors that deliver high torque, and compatibility with various materials to cater to an expansive spectrum of sectors and uses. For those in fields like aerospace, medical equipment production, or the creation of jewelry, these devices offer the requisite precision and effectiveness necessary for breathing life into your projects.

Whether you’re focusing on swift prototyping or producing limited quantities at a time, 5-axis CNC machines refine the manufacturing workflow by curtailing both time spent in production and associated costs. They boast features designed for ease of use which appeal to novices as well as seasoned professionals alike. The dependable performance they provide guarantees uniformity across outcomes. Choosing to invest in a 5-axis desktop CNC machine is bound to significantly bolster your fabrication potential – a strategic move ensuring you keep pace within the fiercely competitive realm of contemporary manufacturing.

Frequently Asked Questions

What is the fastest production time for CNC prototypes at LKprototype?

LKprototype offers an impressive production time of just 1 day for CNC prototypes, ensuring that 97.4% of orders are delivered on-time and in full.

How does CNC prototyping help cut down on production costs?

By enabling the early identification of defects, CNC prototyping contributes to a reduction in production expenses by optimizing the utilization of materials and processes, as well as improving the speed at which iterations are conducted.

Adopting this forward-thinking strategy decreases risks and results in considerable cost reductions throughout the entire manufacturing process.

How many certified materials does LKprototype offer for CNC machining?

LKprototype offers over 65 certified materials for CNC machining. This extensive selection allows for versatility in meeting various project needs.

What are the core advantages of CNC machining?

The core advantages of CNC machining are its impressive precision, efficiency, and ability to produce consistent results repeatedly.

These benefits make it an essential technology in modern manufacturing.

How long does it typically take to complete most CNC machining projects?

Typically, most CNC machining projects take about 5 business days to complete, though simpler parts can often be delivered in as little as 1 day.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype