If you want to outsource vacuum casting China in 2025, you should first decide what your project needs. You also need to get your CAD files ready. Good 3D drawings help suppliers give you fast and correct quotes. You should check the newest cost ranges before you choose. For example, mold costs are often between $200 and $1,000. Per-part costs are usually between $10 and $100.

Cost Type | Cost Range |

|---|---|

Mold Costs | $200 - $1,000 |

Per-Part Costs | $10 - $100 |

Picking the right supplier is very important for quality and delivery. If you know each step of the process, you can avoid mistakes. This also helps you control your budget.

Key Takeaways

Know what your project needs before you outsource. Get your CAD files ready and check prices to get good quotes.

Pick a trusted supplier in China for vacuum casting. Make sure they have experience, use good materials, and talk clearly with you.

Vacuum casting saves money for small or medium orders. It gives good quality and quick results.

Use Non-Disclosure Agreements (NDAs) to keep your designs safe. Make sure you own your molds so no one else can use them.

Set up a strong quality control plan. Check parts often for problems and ask for reports to keep quality high.

Introduction to Vacuum Casting Outsourcing

Why global buyers outsource vacuum casting to China

Many people pick China for vacuum casting. China has many good points for companies around the world. The table below lists the main reasons:

Reason | Explanation |

|---|---|

Precision and Quality | Accurate silicone molds need careful tools. This affects how good the cast parts are. |

Efficiency and Speed | Good tools make work faster. This means molds and resin parts are made quickly. |

Cost-Effectiveness | One mold can make many parts. This keeps costs low for small or medium orders. |

Adaptability and Flexibility | It is easy to change designs or make new versions. Factories do not need to change tools a lot. |

Chinese suppliers use modern tools to make high-quality parts. You pay less because making things in China costs less. If you want changes, Chinese factories can do them fast. Quick work helps you finish your project on time.

Who should read this guide

This guide is for anyone who wants to outsource vacuum casting. It helps product designers, engineers, and buyers. You might work at a new company or a big one. If you need samples, small orders, or special parts, this guide will help you. You will learn how to avoid mistakes and make good choices.

Tip: If you do not know much about vacuum casting, this guide explains every step in easy words. You do not need to be an expert to follow along.

What this guide will cover

This guide talks about all the key things you should know about vacuum casting outsourcing. You will see:

An easy-to-understand look at vacuum casting methods

Information about materials used in vacuum casting

Advice for picking the best vacuum casting supplier

Why supplier skill and knowledge matter

What Is Vacuum Casting? (Quick Overview)

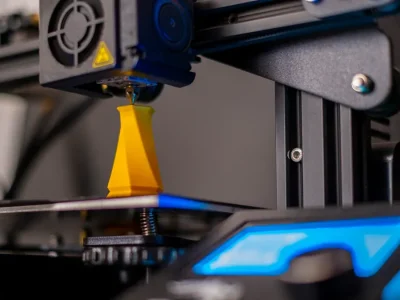

How the vacuum casting process works

Vacuum casting helps make strong plastic parts. First, you need a master model. You can make this model with 3D printing or CNC machining. The process uses silicone molds to copy the master model. Here is how vacuum casting works:

Make a master model with SLA, SLS 3D printing, or CNC machining.

Put the master model in a casting box. Pour platinum-cure RTV silicone over it.

Cut the silicone mold with a wave-line method. This lets you take out the model and put in resin.

Heat the casting resin to 40 °C. This helps the resin flow better.

Fill the mold with resin in a vacuum casting machine. The pressure is 5 mbar or less.

Cure the mold in an oven at 60 °C to 80 °C. This makes the parts strong.

Open the mold and take out the finished part.

Vacuum casting gives you parts that look and feel like real products.

Advantages of vacuum casting

Vacuum casting has many good points. Here are some main benefits:

Cost-effectiveness: Vacuum casting saves money for small and medium batches.

High-quality results: You get smooth surfaces and fine details.

Material versatility: You can use many kinds of resins.

Speed: You can make prototypes fast with vacuum casting.

Customization and complexity: Vacuum casting works for special shapes and designs.

Low-volume production

Vacuum casting is good for making a small number of parts. It works well when you do not need many items.

Complex geometries & fine details

Vacuum casting copies every detail from the master model. You get sharp edges and smooth surfaces.

Cost-effective for prototypes

Vacuum casting helps you save money. You do not need expensive steel molds for prototypes.

Common polyurethane materials used

You can pick from many polyurethane materials in vacuum casting. Here is a table with popular choices:

Material Type | Material Reference | Appearance | Applications |

|---|---|---|---|

PMMA-like | PX 5210 | Transparent | Clear parts that need good transparency and UV resistance |

PC-like | PX520 | White, Clear | Prototype parts with mechanical properties like PC |

Soft-rubber-like | T0387, 8400 | Colorless Transparent, Yellow Transparent | Flexible rubber parts for industry and consumer goods |

ABS-like | Hei-Cast 8150, PZ858, 6160, P+600 | Beige, Black, Milky white | Hard parts for electronic housings and car parts |

PA-like | PX223 | Black, Tawny | Strong parts with properties like nylon |

PP-like | UP 5690 | White, Black | Parts with high impact resistance for bumpers and boxes |

Tip: You can ask your supplier which polyurethane material is best for your project. Vacuum casting lets you choose from many options.

Why Choose China for Vacuum Casting

Lower production cost compared to EU/US

You spend less money in China. Factories pay workers less than in the US or Europe. Materials also cost less there. You still get good parts for your project. Many buyers can buy more parts with their budget. This is true for small and medium orders.

Faster turnaround & flexible batch size

You get your parts fast in China. Most orders take 5 to 10 business days. This helps you finish your project on time. In the US and Europe, you wait longer for parts. Their rules and steps slow things down. Chinese factories make small or big orders. You can ask for a few or many pieces. They change their work to fit your needs.

China: Average lead time is 5–10 business days

US and Europe: Lead times are longer

Wide range of materials & colors

You can pick from many plastics and colors in China. Suppliers offer ABS-like, PC-like, and PA-like plastics. Each type has special features. ABS-like plastics are strong and resist heat up to 77°C. PC-like plastics can be clear or colored. They resist heat over 80°C. PA-like plastics act like nylon and can be made stronger.

Material Type | Available Colors |

|---|---|

Plastic | Natural, Black, Clear, White, Gray, Flame Retardant |

Metal | Yellow, Red, Various Alloys |

Most polyurethanes start out clear or see-through. You can add color before casting. This makes bright colors that last and match your brand.

Mature supply chain (painting, polishing, assembly)

China’s supply chain helps you get finished parts quickly. You get good materials and fast shipping. Factories work with skilled partners for painting and polishing. They also help with assembly. Your parts look nice and arrive on time.

Good material sourcing

Fast and smooth shipping

Easy production and delivery

High production stability for repeat orders

You want every batch to look the same. Chinese suppliers use good molds and careful curing. They check materials to keep parts steady. They watch temperature and timing for each order. You get repeat orders with the same quality.

Factor | Description |

|---|---|

Mold/Pattern Quality | Good molds stop mistakes and keep sizes right. |

Mold Degradation | Factories check molds and replace them if needed. |

Vacuum Leaks | Careful vacuum control stops air bubbles. |

Thermal Effects | Temperature control keeps parts from shrinking. |

Material Properties | Suppliers check thickness for each batch. |

Curing Processes | Timing and environment stay the same for every order. |

Tip: Picking China for vacuum casting gives you fast work, saves money, and brings steady results for every project.

Cost Breakdown of Vacuum Casting in China

Understanding the cost structure helps you plan your vacuum casting project. You can see where your money goes and how to control your budget. Let’s look at the main price components you will find when you outsource vacuum casting in China.

Typical price components

You pay for several steps in the vacuum casting process. Each step adds value to your parts. Here are the main cost components:

Master model / 3D printing cost

You start with a high-quality master model. This model sets the shape and detail for every part you make. You can use 3D printing or CNC machining to create your high-quality master model. The price depends on the size and detail. A simple high-quality master model costs less. A complex high-quality master model with fine features costs more. You need a high-quality master model for each new design. The high-quality master model is the base for the silicone mold.

Silicone mold cost

The silicone mold is the heart of vacuum casting. You pour silicone around the high-quality master model to make the silicone mold. The silicone mold copies every detail from the high-quality master model. You need a new silicone mold for each design or major change. The cost of the silicone mold depends on the size, shape, and number of parts you want. A small silicone mold costs less. A large silicone mold for many parts costs more. The silicone mold can make 15 to 25 parts before you need a new one. You pay for each silicone mold you use. The silicone mold cost is a one-time fee for each batch.

Per-unit casting cost

After you have the silicone mold, you pay for each part you cast. The per-unit casting cost covers the resin, machine time, and labor. The silicone mold lets you make many parts from one high-quality master model. The more parts you make, the lower your average cost. If you order a small batch, the per-unit casting cost is higher. If you order more, the cost per part goes down. The silicone mold helps you save money on each part.

Painting, polishing, and finishing

You may want your parts to look smooth and colorful. Painting, polishing, and finishing add extra cost. You can ask for matte, glossy, or textured surfaces. The silicone mold gives a good base, but finishing makes your parts look even better. If you want special colors, you can add pigment to the resin before casting in the silicone mold. You can also paint the parts after casting. Polishing removes small marks from the silicone mold. Each finishing step adds to the total cost.

Assembly or additional processes

Some parts need assembly or extra steps. You may want to join several cast parts together. You may need inserts, threads, or special coatings. Each extra process adds cost. The silicone mold can include some features, but not all. You pay more for each added step. Ask your supplier what the silicone mold can do and what needs extra work.

Cost comparison: China vs USA vs Europe

You want to know how costs in China compare to other regions. China offers lower prices for vacuum casting. You pay less for the high-quality master model, silicone mold, and per-unit casting cost. Labor and material costs are lower in China. You also get fast service and flexible batch sizes.

Region | Master Model Cost | Silicone Mold Cost | Per-Unit Casting Cost | Finishing & Assembly | Lead Time |

|---|---|---|---|---|---|

China | Low | Low | Low | Low | 5–10 days |

USA | Medium–High | High | High | High | 10–20 days |

Europe | High | High | High | High | 10–20 days |

You save money by choosing China for your vacuum casting project. The silicone mold and high-quality master model cost less. You get more value for your budget.

Factors that affect pricing

Many things can change the price of vacuum casting. You should know what affects your costs. Here is a table that shows the main factors:

Factor | Description |

|---|---|

Equipment Costs | You pay for the machines and tools to make the high-quality master model and silicone mold. |

Material Costs | You pay for the resin and silicone used in the silicone mold and casting. |

Labor Costs | You pay for the workers who make the high-quality master model, silicone mold, and parts. |

Operational Costs | You pay for running the machines and keeping the workshop clean and safe. |

Demand for Production | You pay more if you need fast delivery or special low-volume production. |

Let’s look at some key details:

Complexity of geometry

If your part has many small details, you pay more. The high-quality master model takes longer to make. The silicone mold must copy every feature. Complex shapes need more work and skill. Simple shapes cost less.

Material selection

You can choose from many resins. Some resins cost more than others. If you want special properties, you pay more. The silicone mold works with many materials, but some need extra care.

Surface finishing

You may want a smooth, glossy, or textured surface. The silicone mold gives a good finish, but extra steps add cost. Painting, polishing, and special coatings cost more. The more finishing you want, the higher the price.

Order quantity

If you order more parts, you pay less per part. The silicone mold cost spreads over many pieces. Small orders have a higher cost per part. Large orders give you better value.

Tip: You can ask your supplier for a detailed quote. They will show you the cost for the high-quality master model, silicone mold, per-unit casting, and finishing. This helps you plan your project and avoid surprises.

How to Outsource Vacuum Casting in China (Step-by-Step Guide)

If you want to outsource vacuum casting in China, you should follow a simple process. This helps you avoid problems and get good results. You need to get your project details ready and learn about each step.

Step 1 — Prepare your RFQ

You must send a Request for Quotation (RFQ) to your supplier. This lets the factory know what you need. They can give you the right price.

3D files (STEP/IGS/X-T)

You should give 3D files like STEP, IGS, or X-T. These files show the part’s shape and size. Factories use them to make the master model.

2D drawings with tolerances

You can add 2D drawings with tolerances. These drawings show important sizes and limits. They help the supplier check if the parts are correct.

Material & color requirements

You need to tell the supplier what material and color you want. You can pick ABS-like, PC-like, or other polyurethane materials. You can also choose colors or ask for clear parts.

Quantity & lead time

You should say how many parts you need and when you want them. This helps the supplier plan when to make and send your order.

Tip: If your RFQ is clear, suppliers can give you faster and better quotes.

Step 2 — Mold creation & sample confirmation

The factory uses your 3D files to make a master model. They build a silicone mold around the model. The mold is heated to 60-70℃ to make it accurate. The supplier mixes the casting resin and removes air bubbles. They pour the resin into the mold using a vacuum. The part is baked in an oven before it comes out. Each step makes sure the part matches your design.

Step | Description |

|---|---|

1 | Heat the silicone mold to 60-70℃. |

2 | Remove air from the resin in a vacuum. |

3 | Pour resin into the mold with a vacuum. |

4 | Bake the part in an oven before taking it out. |

Step 3 — Trial production / T1 batch

The supplier makes a small batch called the T1 batch. You get the first samples. The factory checks these samples with special tools. You can look at the samples and see if they are good.

Custom parts are checked for quality before you get them.

You can ask for changes if you need them.

Step 4 — Mass production & QC

If you like the samples, the factory starts making more parts. They use tools like 3D CMM to check sizes, X-ray to look inside, and hardness tests. You get reports and can track each batch.

Quality Control Measure | Purpose |

|---|---|

3D CMM | Checks size and limits |

X-ray Imaging | Finds air bubbles or shrinking |

Hardness Testing | Checks how strong the part is |

Inspection Reports | Gives you papers when you get your order |

Step 5 — Packaging & shipping

The supplier packs your parts so they do not break. You can pick air or sea shipping. The factory gets customs papers ready for export. You get your finished vacuum-cast parts ready to use.

How to Choose a Reliable Vacuum Casting Supplier in China

Picking the right vacuum casting supplier in China is important. It helps you avoid big mistakes and saves money. You want a partner who sends good parts on time. They should also keep your project safe. Use this checklist and advice to help you choose well.

Essential capability checklist

When you look at suppliers, check for these main skills:

Experienced engineering team

You need a supplier with smart engineers. They can fix problems and make your designs better. Ask how many engineers work at the factory. More engineers means more help for hard projects.

Dedicated vacuum casting workshop

A good supplier has a special workshop for vacuum casting. This place should have new machines and a real vacuum casting chamber. Special workshops help keep your parts clean and correct.

Silicone material quality

Good silicone makes better molds. Good molds give you sharp and smooth parts. Ask your supplier which silicone brands they use. The best suppliers pick platinum-cure silicone for top results.

Painting/finishing capability

You might want parts with special colors or finishes. Check if the supplier can paint, polish, or do other surface work. A strong finishing team makes your parts look nice and professional.

Tip: Suppliers with ISO 9001 or other certificates follow strict rules for quality.

Supplier verification steps

You must check if a supplier is honest before you order. Follow these steps to be sure:

Ask for previous sample work

Ask for samples of parts they made before. Samples show if the supplier does careful work. You can also ask for names of other customers.

Check certifications (ISO9001, etc.)

Look for certificates like ISO 9001, ISO 13485, or AS9100. These show the supplier follows world rules. Certified suppliers keep better records and use strict steps.

Evaluate communication speed

See how fast the supplier answers your questions. Fast and clear replies show they care about your project. Slow or unclear answers can cause mistakes and delays.

Supplier Verification Checklist

Step | What to Look For |

|---|---|

Design Tools | New software and trained workers |

Vacuum Casting Chamber | Special tools for master molds |

Turnaround Time | Fast delivery and clear plans |

Performance Metrics | High on-time delivery and reorder rate |

Factory Audits | Willing to let you visit or check |

Note: Always ask for business papers and the factory address. Good suppliers share this information easily.

Red flags when sourcing factories

Watch for warning signs that a supplier may not be good. These red flags can help you avoid problems later.

Unrealistically low pricing

If a price is much lower than others, be careful. Very low prices may mean bad materials or hidden fees. Honest pricing is clear and fair.

No QC reports

Quality control (QC) reports show the supplier checks each batch. If a factory cannot give QC papers, you might get bad parts.

No NDA or contract willingness

A good supplier will sign a Non-Disclosure Agreement (NDA) or contract. If they say no, your designs may not be safe.

Outsourcing to third parties

Some suppliers send your order to another factory without telling you. This can cause bad quality and slow delivery. Always check who will make your parts.

Common Red Flags to Avoid:

Bad communication or slow answers

No references or sample work

Company details you cannot check

Strange payment rules or sudden price changes

Not letting you visit or check the factory

Many quality problems with no fix

Bad news stories or legal trouble

🚩 If you see any of these signs, look for a different supplier. Your project needs a partner you can trust.

IP Protection & Mold Ownership in China

How to protect your design files

You want your design files to stay safe with a Chinese vacuum casting supplier. There are a few ways to lower the chance of leaks or theft. The table below shows some good ways to protect your files:

Method | Description |

|---|---|

Non-Disclosure Agreements (NDAs) | NDAs make sure your design files stay private. |

Limiting File Sharing | Fewer people with access means less risk of leaks. |

Choosing a Full-Service Supplier | Using one supplier helps stop files from being shared too much. |

You should also use safe ways to send and store your files. Ask your supplier if their factory has limited access. NDA rules help keep your designs safe.

How to write an NDA for vacuum casting projects

You need a strong NDA to keep your ideas safe. Write clear rules about what the supplier can do with your files. Say that your designs must stay secret. List who can see the files and who cannot. Make sure the NDA covers every part of the project, from start to finish. Add penalties if someone breaks the rules. Ask a lawyer to check your NDA before you sign it.

Tip: Use easy words in your NDA so everyone knows the rules.

Ensuring mold ownership and preventing unauthorized use

You must make sure you own your molds. Tell your supplier in the contract that you keep all rights to the molds. Write rules to stop others from using your molds the wrong way. Use Non-Disclosure, Non-Compete, and Non-Circumvent agreements to protect your molds. Write down who owns, uses, stores, and takes care of the molds. Add details about how to manage and own the molds. Make sure your agreements follow the law in China and other countries.

Write mold ownership and usage rules in your contract.

Use NDAs and other legal papers to protect your molds.

Say who stores and takes care of the molds.

Check that your agreements follow IP laws.

Best practices for protecting sensitive projects

You should always limit who can see your files. Only share designs with trusted workers. Pick suppliers with safe factories. Ask for updates about where your molds are kept and how they are used. Keep copies of all your contracts and NDAs. Check your agreements often to make sure you are still protected.

🛡️ Keeping your designs and molds safe helps you control your project and avoid big problems.

Quality Control for Vacuum Casting Parts

Quality control helps you get the best vacuum casting parts for your project. You need to know what problems to look for and how to check your parts. You also need a good plan for checking every batch. This section will help you understand the most common defects, what to check, and how to set up a strong QA/QC workflow.

Common vacuum casting defects

You may see some defects in vacuum casting parts. These problems can affect the surface finish, the look, and the strength of your parts. You should know what to watch for.

Air bubbles

Air bubbles can form inside the resin during casting. These bubbles make the surface finish rough and weak. You may see small holes or bumps on the surface finish. Air bubbles can also make clear parts look cloudy. You need to check the surface finish for any signs of bubbles.

Shrinkage

Shrinkage happens when the resin cools and gets smaller. This can change the size and shape of your part. Shrinkage can also cause dents or warping on the surface finish. You may notice that the surface finish does not match your drawing. Always measure your parts and check the surface finish for any changes.

Color inconsistency

Color inconsistency means the color does not look the same on every part. You may see light and dark spots on the surface finish. This can happen if the resin is not mixed well or if the pigment is not added evenly. Color inconsistency can make the surface finish look bad and hurt your brand image. You should compare the surface finish of each part to your color sample.

Surface dents

Surface dents are small marks or dips on the surface finish. These dents can come from poor mold quality or from handling parts the wrong way. Surface dents make the surface finish look uneven. You should check every part for dents and make sure the surface finish is smooth.

Tip: Always ask your supplier to send photos of the surface finish before shipping. This helps you spot defects early.

Inspection checklist for overseas buyers

You need a good checklist to inspect vacuum casting parts from China. This helps you check the surface finish and other key points. Use the table below to guide your inspection process:

Step | Description |

|---|---|

1. Pre-Inspection Prep | Confirm specifications using precise drawings and samples. Create a detailed checklist that classifies all defects, including surface finish issues. |

2. On-Site Inspection | Conduct thorough visual checks and functional testing of each product. Sort into acceptable and defective piles based on surface finish and other criteria. |

3. Rework and Re-Inspection | Isolate defective items, issue a Defect Report, and agree on corrective actions. Verify corrections through re-inspection, focusing on surface finish improvements. |

4. Final Report | Document the total quantity checked, pass rate, defect rate, and include high-resolution photos and objective data analysis of the surface finish. |

You should always check the surface finish at every step. This helps you catch problems before you ship the parts.

Recommended QA/QC workflow

You need a clear workflow to keep the surface finish and quality high. Follow these steps for each order:

Review your drawings and samples. Make sure you list your surface finish needs.

Ask your supplier to send photos of the first parts. Check the surface finish for bubbles, dents, and color.

Use your inspection checklist to check every batch. Look at the surface finish under good light.

Mark any parts with a bad surface finish. Ask the supplier to fix or replace them.

Get a final report with photos of the surface finish. Check the pass rate and defect rate.

Keep records of all reports and photos. This helps you track the surface finish over time.

Note: Good QA/QC helps you get the surface finish you want. It also saves you time and money on rework.

You should always talk with your supplier about your surface finish needs. Clear rules and good checks help you get the best parts every time.

Shipping & Logistics When Ordering From China

Packaging methods for fragile PU parts

You want your vacuum-cast PU parts to arrive safely. Polyurethane (PU) parts can break or scratch during shipping. Chinese suppliers use special packaging to protect them. They often wrap each part in bubble wrap or foam sheets. Some factories use custom-cut foam inserts for extra safety. You may see double-layer cardboard boxes for added strength. If your parts are clear or painted, ask for a plastic film cover to stop scratches.

Packaging Checklist:

Bubble wrap or foam sheets

Custom foam inserts for delicate shapes

Double-layer cardboard boxes

Plastic film for clear or painted parts

“Fragile” labels on the box

Tip: Always ask your supplier to send photos of the packaging before shipping.

Air shipping vs sea shipping

You can choose air shipping or sea shipping for your order. Air shipping moves your parts fast. Most air shipments take 3 to 7 days. This works well for urgent projects or small batches. Sea shipping costs less for large or heavy orders. It usually takes 20 to 40 days. Sea shipping fits big projects with less rush.

Shipping Method | Speed | Cost | Best For |

|---|---|---|---|

Air | 3–7 days | Higher | Small, urgent orders |

Sea | 20–40 days | Lower | Large, heavy orders |

Note: Air shipping gives you speed. Sea shipping saves you money.

Lead time expectations

You should plan for both production and shipping time. Most Chinese suppliers need 5 to 10 business days to make vacuum-cast parts. Air shipping adds about one week. Sea shipping adds three to six weeks. Always confirm the timeline with your supplier before you order.

Example Timeline:

Production: 5–10 days

Air shipping: 3–7 days

Sea shipping: 20–40 days

Customs documents required

You need the right documents to clear customs. Your supplier should prepare these papers for you:

Commercial invoice

Packing list

Bill of lading (for sea) or airway bill (for air)

Certificate of origin (if needed)

HS code for your product

🚚 Always check with your freight forwarder or customs broker for extra rules in your country.

Vacuum Casting vs Other Manufacturing Processes

Vacuum Casting vs Injection Molding

You might ask how vacuum casting is different from injection molding. Vacuum casting is good for making a few parts or samples. You do not need to buy costly steel molds. Injection molding uses strong steel molds and is better for making lots of parts. You pay more at the start for injection molding. Vacuum casting is faster for small orders.

Feature | Vacuum Casting | Injection Molding |

|---|---|---|

Mold Cost | Low | High |

Batch Size | Small to Medium | Large |

Lead Time | Short | Long |

Detail Level | High | High |

Tip: Pick vacuum casting for quick samples or small batches. Choose injection molding if you need many parts.

Vacuum Casting vs CNC Machining

CNC machining cuts parts from solid blocks. These parts are strong and very exact. Vacuum casting uses liquid resin and silicone molds. You can make tricky shapes with vacuum casting. CNC machining works best for metal and hard plastics. Vacuum casting is better for soft or bendy parts.

CNC machining: Good for metal, hard plastic, and exact sizes.

Vacuum casting: Good for tricky shapes, soft materials, and samples.

Vacuum Casting vs 3D Printing

3D printing makes parts one layer at a time. You can make one part at once. Vacuum casting copies a master model to make many parts. Vacuum casting gives smoother surfaces. 3D printing is good for fast changes in design. Vacuum casting is better when you want more parts with nice surfaces.

Feature | Vacuum Casting | 3D Printing |

|---|---|---|

Surface Finish | Smooth | Layered |

Batch Size | Multiple | Single |

Material Choice | Wide | Limited |

Note: Use 3D printing for quick ideas. Use vacuum casting for smoother parts and bigger batches.

When vacuum casting offers the best cost-performance ratio

Vacuum casting is best when you need a few parts fast and with lots of detail. You save money because molds cost less. You can pick from many materials. You can test your design before making lots of parts. Vacuum casting helps you launch new products quickly and keep costs low.

Great for samples and testing ideas

Good for special colors and finishes

Works for small to medium orders

🚀 Vacuum casting lets you turn your idea into a product quickly and with good quality.

Case Study: Outsourcing Vacuum Casting to China

Project background

You work for a small electronics startup. Your team needs 50 custom plastic housings for a new smart sensor. You want the parts to look professional and feel strong. You also need them fast for a product demo. Local suppliers give you high quotes and long lead times. You decide to try a Chinese vacuum casting supplier.

Timeline & workflow

You start by sending your 3D CAD files and a list of requirements to the supplier. The supplier reviews your files and sends a quote within two days. You approve the price and pay for the master model and silicone mold. The supplier makes the master model using 3D printing. They create the silicone mold and send you photos for confirmation.

Here is a simple workflow you follow:

Send RFQ with 3D files and requirements.

Approve quote and pay deposit.

Review master model photos.

Approve silicone mold photos.

Receive T1 samples in five days.

Approve samples and start mass production.

Receive finished parts in ten days.

Tip: Clear communication helps you avoid delays.

Cost comparison

You want to know how much you save. The table below shows the cost difference:

Item | China Supplier | Local Supplier |

|---|---|---|

Master Model & Mold | $400 | $1,200 |

Per-Part Cost | $18 | $45 |

Lead Time | 15 days | 30 days |

You save over 60% by choosing the Chinese supplier. You also get your parts twice as fast.

Final results & lessons learned

You receive all 50 housings on time. The parts look smooth and match your design. You check the fit and finish. Everything meets your needs. You learn that clear files and fast replies help the process. You also see that picking a supplier with good reviews makes a big difference.

Note: Careful planning and supplier checks help you get the best results from China.

Conclusion

Why China remains the best choice for vacuum casting

You get many advantages when you choose China for vacuum casting. Chinese suppliers offer lower costs, fast production, and a wide range of materials. You can order small or large batches. Many factories have skilled workers and modern machines. They can handle complex designs and tight deadlines. You also find strong supply chains for painting, polishing, and assembly. This means you get finished parts ready for use.

Tip: You can save up to 60% on costs and cut your lead time in half by working with the right Chinese supplier.

Final recommendations for buyers

You should follow a clear process to get the best results. Here are some steps to help you succeed:

Prepare your 3D files and drawings before you ask for a quote.

List your material, color, and quantity needs.

Check the supplier’s skills and ask for sample work.

Sign an NDA to protect your designs.

Review samples before mass production.

Ask for quality reports with each order.

Step | Why It Matters |

|---|---|

Good RFQ | Gets you fast, accurate quotes |

Supplier check | Avoids delays and bad parts |

Sample review | Ensures your design is right |

How to avoid risks and ensure stable quality

You can avoid most risks by staying alert and asking questions. Pick suppliers with ISO certificates and good reviews. Always check for clear communication. Make sure you own your molds and sign contracts. Use a checklist for quality control. Ask for photos and reports before shipping.

🚦 Stay involved at every step. This helps you catch problems early and keeps your project on track.

You can use this guide as your checklist. If you follow these steps, you will get high-quality vacuum casting parts from China every time.

FAQ — Frequently Asked Questions

How long does silicone mold last?

A silicone mold can be used 15 to 25 times. The number depends on the part’s shape and resin type. Simple shapes help the mold last longer. Sharp edges or tricky designs wear out the mold faster. You should ask your supplier how long your mold will last.

Tip: If you need more parts, ask for a new mold. This keeps your parts looking good.

What tolerances can vacuum casting achieve?

Vacuum casting can make parts with ±0.2 mm tolerance. Simple shapes are more accurate. Thin walls or tiny details may change the tolerance. Tell your supplier what tolerance you need before they start.

Feature | Typical Tolerance |

|---|---|

Standard Parts | ±0.2 mm |

Complex Parts | ±0.3 mm |

Can vacuum casting produce clear/transparent parts?

Yes, vacuum casting can make clear or see-through parts. Suppliers use PMMA-like or PC-like polyurethane resins for this. Tell your supplier if you want very clear parts. They can polish or use special resins to make them look better.

How fast can Chinese suppliers deliver?

Chinese suppliers usually finish orders in 5 to 10 business days. Air shipping can get your parts to you in less than two weeks. Big orders or special finishes may take more time. Always check the timeline before you order.

Can suppliers match Pantone colors?

Suppliers can match Pantone colors for your parts. They mix pigment into the resin before casting. Give your supplier the Pantone code for your color. Some suppliers send color samples for you to check.

Note: Color matching works best for solid colors. Clear parts may look lighter than you expect.

Can vacuum-casted parts be painted or UV-finished?

You can ask for painting or UV finishing on your parts. Many suppliers offer matte, shiny, or textured looks. UV coating protects the surface and makes it shiny. Say what finish you want in your RFQ.

Painting: Adds color and style

UV finishing: Makes parts stronger and look better

You can get accurate parts and save money with vacuum casting in China. First, get your files and needs ready. Pick a supplier in China who does vacuum casting well. Make sure they care about making precise parts. Check if they have made good prototypes before. Ask how they use casting resin and control quality. China helps you spend less and get parts quickly. Follow this guide to plan your costs and time. You will get good prototypes with accuracy from vacuum casting in China.

LKprototype

LKprototype