A data-driven approach changes manufacturing by making it more efficient. You can use real-time data and analytics to find hidden problems fast. This helps you fix things quickly. Companies like Toyota and General Electric have made big improvements. They cut production defects by 45%. They also reduced inspection time by 75%.Data-driven manufacturing process optimization often gives a 5-6% boost in productivity. It also saves a lot of money. By tracking key metrics, you make sure every process change shows real results. Key Takeaways Real-time data lets factories spot problems quickly and fix them fast before they cause delays or mistakes.…

An automated manufacturing process uses machines and technology to do production work. Control systems help finish tasks with little help from people. This method tries to make work faster, more correct, and more productive. It also helps cut down on hard work and mistakes. In the past ten years, factories have used more robots and AI. This has made production reach new highs. The table below shows how automation helps make work better and more correct in factories: Benefit AreaStatistic / ImprovementConveyor systemsProductivity increase by 60%RFID technologyInventory accuracy improved to 99%Human-robot teams85% more productive than only humans or only robots…

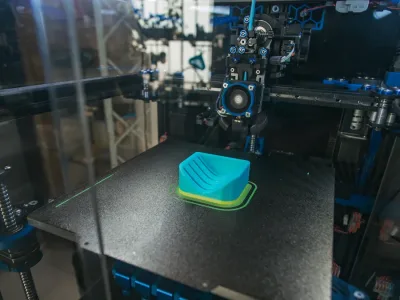

Additive manufacturing process involves creating objects by adding layers based on digital plans. Today, companies use this additive manufacturing process to produce car parts and medical tools. Imagine a designer with a new product idea—this additive manufacturing process allows them to quickly test models. They can begin mass production much sooner than before. Nearly 70% lower prototyping costs help companies save money. Lead times shrink from weeks to days, enabling faster responses. Up to 90% less wasted material benefits the environment. Every step in the additive manufacturing process is crucial. Designers select the best materials and settings to ensure parts…

You need to understand the contract manufacturing process to see how it works. Contract manufacturing is when you allow another company to produce your product. You provide your product design and requirements to the contract manufacturing company, and they handle the production for you. This contract manufacturing process helps many businesses save money and operate more efficiently. The table below shows that contract manufacturing is expanding worldwide. Metric/SegmentValue (2023/2024)Projected Growth/NotesGlobal contract manufacturing marketUSD 334.09 billion (2023)CAGR 9.32% (2024-2031), projected USD 676.76 billionPharmaceuticals & biopharmaceuticals32.35% market share (2023)Expected USD 225.24 billion by 2031End-to-end manufacturing segmentUSD 141.17 billion (2023)Highlights efficiency via integrated…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.