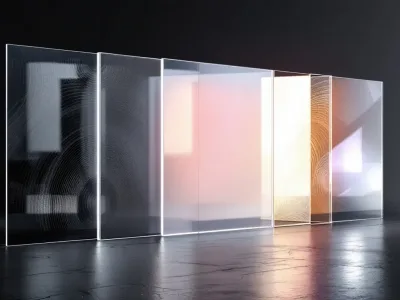

Acrylic CNC machining uses computer-controlled devices to accurately cut and shape acrylic materials. It provides precision, reduces material waste, and speeds up production compared to manual methods. In this article, you’ll learn about the advantages, key properties, and best practices for achieving high-quality results in acrylic CNC machining. Key Takeaways CNC machining offers high precision and speed for acrylic, significantly reducing material waste and production costs, making it an efficient manufacturing method. Key properties of acrylic, including its transparency, impact resistance, and lightweight nature, contribute to its widespread use in industries such as automotive, medical, and construction. Implementing best practices…

This guide will explore the most common CNC machining types and their applications in precision manufacturing. Key Takeaways CNC machining encompasses various machine types, including milling, lathes, and laser cutters, each suited for specific manufacturing processes and industries. The selection of the appropriate CNC machine depends on factors such as material type, part complexity, and required precision, crucial for optimizing manufacturing efficiency. CNC machining provides significant advantages like precision and uniformity, but it also poses challenges such as higher costs and system complexity, necessitating proper training for effective operation. CNC Milling Machines CNC machines, specifically CNC milling machines, are pivotal…

CNC machinists operate computer-controlled machines to produce precision parts and components. This crucial role involves programming and maintaining equipment to meet detailed design specifications. As technology advances, the demand for skilled CNC machinists is rising, making this a promising career path. This article will outline the duties of the CNC machinist, required skills, and career opportunities. Key Takeaways CNC machinists are essential in modern manufacturing, requiring a mix of technical skills, attention to detail, and strong problem-solving abilities to ensure precision in high-quality component production. The career path for CNC machinists is promising, offering opportunities for advancement into specialized roles,…

Understanding the right CNC file format is crucial for precision machining. Key formats like G-code, STEP, and DXF ensure your CNC projects run smoothly and accurately. This article will guide you through these essential formats and their roles in CNC machining. Key Takeaways The essential CNC file formats for precision machining include G-code, STEP, and DXF, each serving unique roles in maintaining accuracy and compatibility. Conversion of CAD files into CNC-compatible formats through CAM software is crucial for precise machining instructions and reduces the risk of errors. Effective communication with CNC technicians and detailed preparation of CAD files are vital…

4 axis CNC machines add a rotational axis to traditional CNC machining, making them capable of complex and precise parts. Industries like aerospace and medical devices rely on them for their versatility. This article covers how 4 axis CNC works, its benefits, and comparisons with 3 and 5 axis machines. Key Takeaways 4-axis CNC machining enhances precision and efficiency by incorporating an additional rotational axis, allowing for complex geometries to be produced without repositioning the workpiece. Compared to 3-axis and 5-axis machines, 4-axis CNC machines provide a balanced option for intricate part production that requires both versatility and cost-efficiency. Regular…

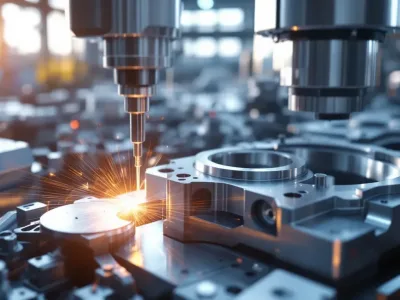

CNC precision machining is the method of using computer-controlled machinery to create parts with extreme accuracy. It’s crucial for industries where tight tolerances and high-quality standards are non-negotiable, such as aerospace, medical, and automotive. In this article, we delve into the processes, advantages, and wide-ranging applications of CNC precision machining. Key Takeaways CNC precision machining is a computer-controlled process that significantly enhances manufacturing efficiency and accuracy by automating material removal and minimizing human error. Achieving tight tolerances is essential in CNC machining, particularly in industries such as aerospace and medical, where precision directly impacts safety and performance. Recent innovations such…

CNC metal machining uses computer-controlled tools to precisely cut and shape metal into custom parts with high accuracy and efficiency. This guide explores CNC machining processes, machine types, metals used, and key steps to produce high-quality parts. Key Takeaways CNC metal machining utilizes automated systems for precise manufacturing, enhancing efficiency and safety compared to traditional methods. Various types of CNC machines, including milling machines, lathes, and multi-axis machines, cater to different machining needs and capabilities. CNC machining’s cost and efficiency are influenced by factors such as part complexity, material choice, and production volume, making it a versatile option for various…

Automotive CNC machining plays a crucial role in manufacturing precise and reliable car parts. From engine components to suspension systems, this technology enhances vehicle performance and efficiency. Read on to discover its applications, benefits, and why it’s vital in the automotive world. Key Takeaways CNC machining is essential in automotive manufacturing for producing high-precision components, including engine parts, transmission elements, and suspension systems, enhancing overall vehicle performance and safety.Advanced technologies, such as AI and IoT, are transforming CNC machining by improving operational efficiency, precision, and integration in the automotive sector, enabling rapid prototyping and smart manufacturing practices.Sustainable practices in CNC…

CNC machining products are essential in automotive, aerospace, electronics, and healthcare industries. They are also crucial in the defense industry for producing weapons, ammunition, and military vehicles, as well as in the marine industry for creating durable, corrosion-resistant parts for vessels. These parts offer unparalleled precision and consistency. This article explores the key CNC machined components and their diverse applications. Key Takeaways CNC machining enhances efficiency, precision, and consistency in producing critical components across industries such as automotive, aerospace, electronics, healthcare, defense industry, and marine industry. The technology supports a wide range of materials, including metals and plastics, allowing manufacturers…

Automotive CNC machines are vital for modern vehicle manufacturing, providing the precision needed for components like engines and transmissions. Discover how automotive CNC machine technology enhances quality and efficiency across the automotive industry. Key Takeaways CNC machining enhances precision, speed, and efficiency in automotive manufacturing, crucial for producing complex components while meeting stringent safety standards. Key applications of CNC machining in the automotive industry include the production of engine components, transmission systems, and interior/exterior panels, all requiring high precision for optimal performance. Emerging trends in CNC machining, such as the integration of AI and the use of advanced materials, are…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.