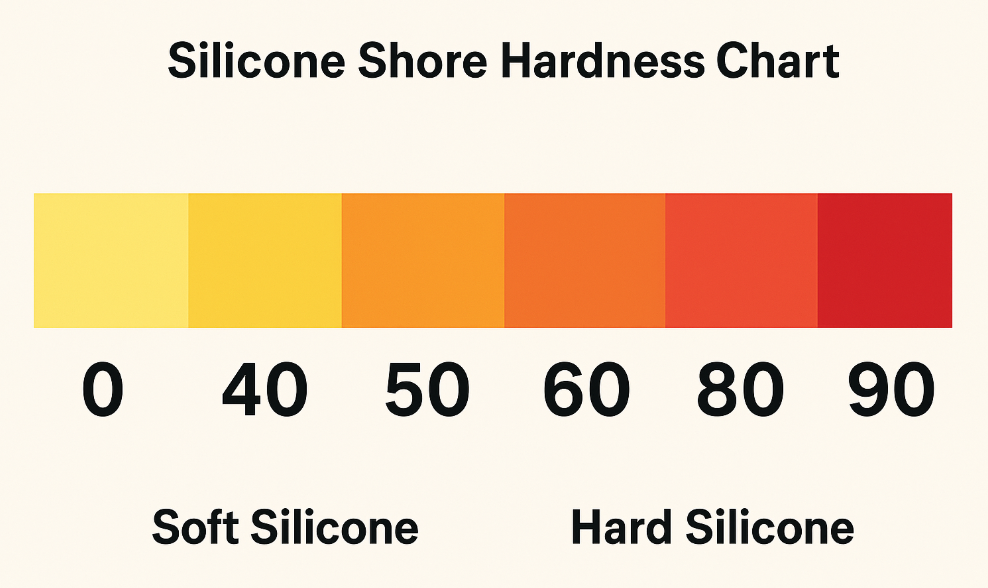

Imagine you need to pick the right silicone part for a seal or a gasket. How do you know if it will be soft enough to seal or hard enough to hold its shape? The silicone shore hardness chart is your go-to tool for answering these questions quickly. By referring to the silicone shore hardness chart, you can easily compare different silicone materials and make informed choices for your projects. This quick understanding leads to better engineering decisions.

Key Takeaways

Always look at the shore hardness number before you pick silicone. This number tells you if the material is soft or hard. It helps you choose the right one.

Use the silicone shore hardness chart to compare types fast. The chart shows which materials work best for your project.

Think about how you will use the silicone when you choose hardness. Softer silicones work well for seals and cushions. Harder silicones are better for strong parts.

Try out silicone samples in real-life situations before you decide. This makes sure the material works well for your project.

Do not mix up shore hardness scales. Shore A is for flexible silicone. Shore 00 is for softer gels. Shore D is for harder plastics.

What Is Silicone Shore Hardness?

Definition of Shore Hardness

Engineers often talk about shore a hardness when picking silicone. Shore hardness is a number from 0 to 100. This number shows how much a material can resist being pressed in. A special tool called a durometer measures this. Albert F. Shore made this system in the 1920s. Today, you see it in rules like ASTM D2240 and ISO 7619-1. When you push the durometer into silicone, it checks how deep it goes. This gives you a clear shore a hardness value. You use this number to compare silicone products fast.

Tip: Always look at the shore a hardness before choosing silicone. This number helps you guess how the material will act in your project.

Shore hardness testing uses a simple method. You press the probe into the silicone and read the number. The test follows strict rules for good results. These rules are in ASTM D2240 and ISO 48-4. The durometer pushes with a force between 3.924 and 50 newtons. You check hardness by how deep the probe goes, not by the mark it leaves.

Why Hardness Matters in Silicone Materials

You need to know the shore a hardness of silicone. It changes how the material acts. Soft silicone with low shore a hardness bends easily and seals well. Hard silicone with high shore a hardness keeps its shape and does not wear out fast. When you pick silicone for gaskets, seals, or flexible parts, you look at the shore a scale. This scale helps you match the material to your needs. If you pick the wrong shore a hardness, your part may break or not work right.

Soft silicone (low shore a hardness) is best for seals and cushions.

Hard silicone (high shore a hardness) is good for strong parts and surfaces that get worn.

The shore a scale helps you compare choices and make smart picks.

Common Hardness Scales Used for Silicone (Shore 00, A, D)

There are three main scales for measuring silicone hardness. Each scale fits a different kind of silicone. The shore a scale is used most for flexible silicone. You use the shore a scale for most engineering parts. Shore 00 is for very soft gels and rubbers. Shore D is for hard plastics and stiff silicone.

Shore Hardness Scale | Description |

|---|---|

Shore 00 | Measures rubbers and gels that are very soft. |

Shore A | Measures flexible mold rubbers from very soft to hard with almost no bend. Semi-rigid plastics can also be measured at the high end. |

Shore D | Measures hard rubbers, semi-rigid plastics, and hard plastics. |

You should always check which scale fits your silicone part. Most engineers use the shore a scale for gaskets, seals, and flexible pieces. When you see shore a hardness listed, it comes from the shore a scale. This makes it easy to compare products and pick the right silicone for your job.

Understanding Shore A for Silicone

Why Shore A Is the Industry Standard for Silicone

Engineers use the shore a scale a lot with silicone. This scale is the main way to measure silicone hardness. It works well for flexible mold rubbers and elastomers. The shore a scale is best for softer materials like silicone. You need this scale when parts must bend or not get pressed in too much.

The shore a scale covers many hardness levels for flexible things.

It is made for softer stuff, so it is great for silicone.

You use it for parts that need to bend or not get squished.

How the Shore A Test Works

You use a tool called a durometer to check shore a hardness. You press the durometer’s probe into the silicone. The tool gives a number from 0 to 100. Hard silicone gets a high number. Soft silicone gets a low number. You must follow rules to make sure the test is right. Most silicone parts, like seals and gaskets, use the shore a scale.

Interpreting Shore A Numbers (Soft → Hard)

You need to know what the shore a number means. The shore a scale helps you see if silicone is soft or hard.

The shore a scale shows how much a material can resist being changed.

A higher shore a number means the silicone is harder.

For example, silicone with shore a 30 is much softer than silicone with shore a 70.

You use the scale to compare silicone, but you cannot compare numbers from other scales.

Tip: Always look at the shore a number before picking silicone for your project.

Comparison: Shore A vs Shore 00 vs Shore D

You might see other scales like shore 00 and shore D. The shore a scale is for most silicone parts. Shore 00 is for very soft gels. Shore D is for hard plastics.

Scale | Best For | Typical Range |

|---|---|---|

Shore 00 | Very soft gels/rubbers | 10–60 |

Shore A | Flexible silicone/rubber | 10–90 |

Shore D | Hard plastics | 30–90 |

You should use the shore a scale for flexible silicone. This gives you the best results for your engineering work.

Silicone Shore Hardness Chart (Quick Reference)

Silicone Hardness Table (10A–90A)

Sometimes you need to compare silicone types fast. The silicone shore hardness chart helps you see which ones are soft or hard. You can use this chart to find the right silicone for your job. The table below lists the most common hardness levels you will find in engineering.

Shore A Hardness | Description | Typical Uses |

|---|---|---|

10A | Ultra-soft, bends easily | Soft molds, cushioning pads |

20A | Very soft, flexible | Seals, soft-touch parts |

30A | Soft, compressible | Gaskets, flexible covers |

40A | Medium-soft, pliable | O-rings, tubing |

50A | Medium, general purpose | Seals, vibration dampers |

60A | Medium-hard, durable | Industrial gaskets, pads |

70A | Hard, holds shape | Structural seals, spacers |

80A | Very hard, stiff | Rigid parts, wear surfaces |

90A | Extra-hard, does not bend | Heavy-duty seals, bushings |

The silicone shore hardness chart lets you check which hardness is best for you. This chart helps you not make mistakes and choose the right silicone for your design.

Visual Hardness Comparison (Optional Image / Chart)

You might want to know how the silicone shore hardness chart shows soft and hard silicone. Here is an easy way to understand it:

10A materials are very soft. You can bend them with little effort. They are good for showing small details.

30A to 50A materials are soft to medium. You can press them, but they keep their shape.

70A to 90A materials are hard. You cannot bend them much. They are very strong and stay in shape when pressed.

Tip: Use the silicone shore hardness chart to see how each material acts when pressed. The chart helps you pick the best silicone for your project.

You can trust the silicone shore hardness chart to help you with the shore hardness scale. This chart helps you make good choices every time you pick silicone.

Typical Applications by Silicone Hardness

10A–30A: Ultra-Soft Silicone

Ultra-soft silicone is used when comfort is important. Silicone with shore A hardness from 10A to 30A feels very soft. It bends easily and is flexible. You use it for special effects and medical devices. It is also good for soft cushioning. The table below lists common uses for this type:

Application Type | Description |

|---|---|

Skin Effects | Used for making realistic skin in movies and special effects. |

Production Molds | Good for making molds for casting different materials. |

Medical Prosthetics | Used for medical prosthetics because it is flexible. |

Cushioning Applications | Used where soft cushioning is needed. |

Ultra-soft silicone is picked when you want gentle contact. It is great for a soft touch. These uses need low hardness because the material changes shape and absorbs pressure.

30A–50A: Soft to Medium Silicone

Soft to medium silicone is good when you need both flexibility and some strength. You find this hardness in seals and gaskets. It is also used in tubing. These uses need silicone that can be pressed but still keeps its shape. You use this range for O-rings and vibration dampers. It is also used for flexible covers. This material works for many engineering jobs because it is soft and strong.

Tip: Choose soft to medium silicone for seals that also need to move.

50A–70A: Industry-Standard General-Purpose Silicone

Silicone with hardness from 50A to 70A is used for many jobs. This range gives you both strength and flexibility. You use it for industrial gaskets and pads. It is also used for structural seals. These uses need silicone that does not wear out and keeps its shape. You see this hardness in many factories and engineering places.

70A–90A: Hard & Structural Silicone

Hard silicone with shore A hardness from 70A to 90A is used for tough jobs. You pick it when you need strength and stability. It does not change shape easily. Common uses include:

Car parts like gaskets and seals that handle stress and heat.

Machines where silicone gives support and does not wear out.

Mold making for hard molds that keep their shape after many uses.

Industrial parts like vibration dampeners and shock absorbers that take a lot of force.

Products like bakeware and covers that need to be strong and resist heat.

Hard silicone is chosen for jobs that must last and work well under tough conditions. This hardness keeps your parts strong and dependable.

How to Select the Right Silicone Hardness

Engineering Factors to Consider

When picking silicone, you need to think about a few things. Each thing helps you know which silicone is best. The table below lists the main things to check:

Factor | Description |

|---|---|

Flexibility | Softer silicones are best when you need lots of bending. |

Durability | Harder silicones work better for strong parts that must last. |

Environmental Resistance | Think about where the part will go and what it faces. |

Ask yourself if your part needs to bend a lot. If yes, pick a softer silicone. If you want it to stay strong, use a harder one. Always think about where you will use the part. Some places need silicone that can handle heat, water, or chemicals.

Tip: Try out a sample before you decide. This lets you see how the silicone works in real life.

Application-Based Hardness Recommendations

You can choose silicone hardness by thinking about what the part does. Silicone uses the Shore A scale, from 10° to 80°. This big range helps you find the right one for many jobs. Here are some common uses:

Soft silicone works well for edging strips that must bend.

Cars use silicone for hatch seals and other parts. These need medium or hard silicone to work well.

Medicine and boats use silicone for inflatable seals and special parts. These need the right hardness to handle tough places.

Always check what your part needs before you pick silicone. The right hardness makes your part last longer and work better.

Material Selection Decision Flowchart (Optional)

A simple flowchart can help you pick the right silicone:

Decide if your part should bend or stay firm.

Think about where the part will be used.

Pick a hardness based on how much it needs to bend, last, and resist things.

Try a sample to make sure you picked right.

If you follow these steps, you will pick the best silicone. You will not make mistakes and your project will turn out better.

Common Mistakes & Troubleshooting Hardness Issues

Selecting Hardness Based Solely on Number

Some people think the shore hardness number is all they need. This can cause problems later. The number shows if silicone is hard or soft. But it does not tell you everything about the material. You should see how silicone works in your project. Two silicones with the same number can feel different. This happens because of their formula or how they are made. Always test silicone in real life before you choose.

Tip: Do not trust only the shore hardness number. Make sure to check how silicone works in your project.

Confusing Shore A with Other Scales

You might see Shore A, Shore 00, or Shore D on charts. Mixing these scales up can lead to mistakes. Each scale is for a different kind of material. If you use the wrong scale, your silicone may not work. Using the right Shore scale helps you get correct results. Not every material can be tested with Shore hardness. Testing the wrong thing can give you errors. You need to use good testing methods for true hardness numbers.

Always check which scale fits your silicone part. Shore A is for flexible silicone. Shore D is for hard plastics. Shore 00 is for very soft gels.

Why Hardness May Vary Between Manufacturers

Sometimes two silicones have the same shore hardness number but feel different. This is because makers use different formulas and ways to make silicone. Some companies add fillers or change how they cure the silicone. These things change how hard or flexible the silicone is. Always ask for a sample or test piece before you pick a product.

Reason for Variation | What You Should Do |

|---|---|

Different formulas | Ask for a sample |

Unique curing processes | Test it in your project |

Added fillers | Compare products yourself |

How to Verify Hardness with Sample Testing

You can check silicone hardness with a durometer. Press the tool into the silicone and read the number. Always follow the right steps when testing. Test more than one spot for a true reading. Try the silicone in your real project. This helps you see if it bends, seals, or stays strong.

Note: Sample testing is the best way to know how silicone will work in your project. Never skip this step.

Engineering Use-Cases & Real Examples

Gaskets / O-Rings

Silicone gaskets and O-rings are used in machines. These parts help seal joints and stop leaks. You need to pick the right silicone hardness for these parts. Softer silicone (30A–50A) bends and seals tight. Harder silicone (60A–70A) keeps its shape under pressure. You find these parts in cars, pumps, and plumbing.

Tip: Choose a hardness that fits your system’s pressure and heat. Softer gaskets seal well but may not last as long.

Medical & Soft-Touch Silicone Parts

Silicone is used in many medical and soft-touch items. The hardness changes how these parts feel and work. Softer silicone feels nice and fits the body better. Harder silicone lasts longer and does not break easily. Soft silicone is used for prosthetics, tubing, and skin-contact items.

Property | Description |

|---|---|

Hardness | Changes how flexible, strong, and comfy medical parts are. |

Tensile strength | Shows how much pulling force the part can take. |

Compression set | Low numbers mean the part keeps its shape longer. |

Fluid resistance | Helps silicone work in many medical jobs. |

Flexibility | More flexibility means better comfort for people. |

Hygienic quality | Stops germs and fungi, which is good for skin-contact parts. |

You should check these things when picking silicone for medical use. Softer silicone is good for comfort. Harder silicone is good for lasting longer.

Industrial Sealing Components

Factories and big machines use silicone for sealing. These seals keep out dust, water, and chemicals. Hard silicone (70A–90A) is best for tough jobs. It stays strong when it gets hot or squeezed. You see these seals in pumps, valves, and machines. Pick the hardness based on how much heat and force the seal will face.

Hard silicone lasts longer and does not wear out fast.

Softer silicone seals well but may not last in rough places.

Consumer Electronics Silicone Parts

Silicone is used in phones, tablets, and keyboards. The right hardness keeps parts both flexible and strong. You look at Shore A ratings to pick the best one. This helps you balance softness and strength. Softer silicone protects devices from drops. Harder silicone gives shape and helps buttons work well.

Note: Always pick silicone hardness that fits your device’s needs. Soft silicone helps with bumps. Hard silicone supports moving parts.

FAQs About Silicone Shore Hardness

Is 60A silicone soft or hard?

You might ask if 60A silicone is soft or hard. Silicone with 60A shore a hardness is medium-hard. You can bend it, but it takes some effort. It keeps its shape well. Many engineers use 60A silicone for gaskets and pads. These parts need to be strong and a little flexible.

Tip: Pick 60A silicone if you want something that does not bend too easily but still seals well.

What hardness is best for sealing gaskets?

You want your gasket to seal tight and last a long time. Most gaskets use silicone with shore a hardness from 30A to 60A. Softer silicone (30A–40A) is good for low-pressure seals. Medium silicone (50A–60A) works for higher pressure or harder jobs. Always match the hardness to what your system needs.

Application | Recommended Hardness |

|---|---|

Low-pressure | 30A–40A |

General-purpose | 50A–60A |

High-pressure | 60A–70A |

Is silicone with 40A good for wear resistance?

Silicone with 40A hardness is soft and bends easily. You can use it for seals and O-rings that need to bend. If you want something that lasts longer, pick a harder silicone like 60A or more. Softer silicone can wear out faster if used in rough places.

Can I convert between Shore A, D, and 00?

You might see Shore A, Shore D, and Shore 00 scales. Each scale is for different materials. You cannot change one scale to another directly. If you need to compare, use a chart from the maker. Always check which scale is right for your silicone part.

Note: Using the wrong scale can make you pick the wrong material.

Why do two 50A silicones feel different?

You may find that two silicones with 50A shore a hardness feel different. This is because companies use different recipes and ways to make silicone. Fillers and other things can also change how it feels. Always test a sample before you choose.

What hardness is used for food-grade silicone products?

Food-grade silicone needs to be safe and flexible. Most food-safe items use silicone with shore a hardness from 30A to 60A. This range gives you both softness and strength. You see this in baking mats, spatulas, and bottle nipples.

Tip: Always check for food safety labels when picking silicone for food.

Downloadable Silicone Hardness Chart (Optional Resource)

Printable PDF Version

You can make your job easier with a silicone shore hardness chart. This chart lets you compare silicone types fast. It shows the shore A scale and common hardness numbers. You also see what each type is used for. The chart has a guide for durometer readings. If you want to check silicone hardness, you use a durometer tool. The chart matches durometer numbers to real-life uses. You can print the PDF and keep it at your desk. You can also share it with your team.

Tip: You can download a hardness chart PDF to help you quickly view the hardness value of silicone parts.

To get the PDF, click the download link on this page. The chart has a table with shore A numbers and durometer details. It also lists sample uses. You see how durometer readings help you pick silicone for seals, gaskets, and covers.

Engineering Reference Chart for Design Teams

Your team can use the chart to make good choices. The chart lists durometer numbers from 10A to 90A. You see which number fits each job. The chart helps you avoid mistakes when picking silicone hardness. You use durometer testing to check if the silicone is right for your needs.

Here is a sample table from the chart:

Shore A Value | Durometer Reading | Typical Use |

|---|---|---|

20A | Very soft | Soft seals, cushions |

40A | Medium-soft | O-rings, tubing |

60A | Medium-hard | Industrial gaskets |

80A | Very hard | Rigid covers, bushings |

You use a durometer to test silicone samples. Your team can compare durometer numbers and pick the best one. The chart helps you see how durometer values change flexibility and strength. You can share the chart with engineers, designers, and buyers. Everyone gets the same facts for picking durometer numbers.

Note: Durometer numbers can change with different silicone mixes. Always test with a durometer before making your final choice.

You make better choices when you use the downloadable chart. You save time and avoid mistakes when picking materials.

You can use the shore hardness chart to make smart choices for your projects. The shore scale helps you compare silicone types fast. Always check the shore number before you pick a material. The shore chart shows you which silicone is soft or hard. You should test the shore hardness with a durometer. The shore value tells you how the silicone will act. You need to match the shore rating to your job. The shore chart helps you avoid mistakes. You can share the shore chart with your team. The shore scale works for gaskets, seals, and covers. You should print the shore chart for quick reference. The shore number helps you pick the right silicone every time. The shore chart gives you practical tips. You should always consult the shore chart and checklist before you decide.

Tip: Use the shore chart to save time and get better results.

LKprototype

LKprototype