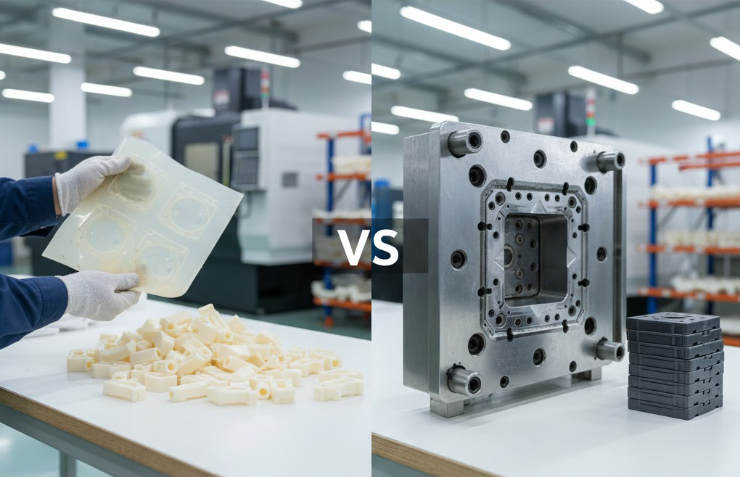

If you want to work fast and save money, use silicone molds for small batches. You get quick results and can change things easily. This works best if you make less than 500 pieces. However, when considering silicone mold vs steel mold, if you need more parts or stronger molds, it's time to switch to steel molds. Steel molds last much longer and can create tricky shapes very well.

Steel molds, especially heat-treated steel, last five to ten times longer than aluminum. This makes them better for making lots of parts.

Here is a simple look at why makers change from silicone mold to steel mold:

Reason | Explanation |

|---|---|

Durability | Steel molds are stronger than silicone molds. They work well for making lots of parts. |

Cost-Effectiveness | If you make more than 100,000 pieces, steel molds save money even though they cost more at first. |

Precision in Complex Shapes | Steel molds can make hard shapes very exactly. This matters when you make more parts. |

Knowing the cost, wait time, and how hard the design is helps you choose when to switch from silicone mold to steel mold for small batch making.

Key Takeaways

Use silicone molds for small batches under 500 pieces. They are quick and cost-effective for prototypes.

Switch to steel molds when producing over 10,000 parts. They last longer and reduce the cost per part over time.

Consider aluminum molds for runs between 100 and 2,500 parts. They offer a good balance of cost and durability.

Evaluate your production needs carefully. The right mold choice saves time and money in the long run.

Consult with a mold expert before making a decision. They can help you choose the best option for your project.

Introduction: The Low-Volume Tooling Dilemma

Defining the Tooling Types: Soft vs. Hard

When you start a new project, you face a big choice: soft tooling or hard tooling. Soft tooling, like silicone molds, works best for small batches and prototypes. Hard tooling, such as steel molds, is made for big runs and long-lasting use.

Here’s a quick look at how they compare:

Factor | Soft Tooling | Hard Tooling |

|---|---|---|

Cost | Low upfront | High upfront |

Lead Time | Short (days-weeks) | Long (4–8 weeks) |

Best Use Case | Prototyping, low-volume | High-volume, long life |

Soft tooling gives you fast results and keeps costs down when you only need a few parts. Hard tooling takes longer and costs more, but it pays off if you plan to make thousands of pieces.

The Core Question: Finding the Cost and Quantity Tipping Point

You might wonder, “When should I switch from soft to hard tooling?” The answer depends on how many parts you need and how much you want to spend per part. As you make more parts, the cost per piece drops, especially after you reach a few thousand. For most projects, the tipping point for switching from silicone to steel molds falls between 500 and 2,500 parts. Silicone molds usually last for 15–30 parts, so they work well for small runs. If you need more, steel molds start to make sense.

Tip: In low-volume manufacturing, you also face challenges like higher per-unit costs, less automation, tricky supply chains, and sometimes you have to make design compromises.

Why Aluminum Molds are the Critical Middle Ground

Aluminum molds sit right between silicone and steel. They cost less than steel molds and work better for low volumes than steel. Aluminum molds heat up and cool down faster, which means you get parts quicker and with fewer defects. If you want to change your design, it’s easier to fix an aluminum mold than a steel one.

Advantage | Aluminum Molds | Steel Molds |

|---|---|---|

Tooling Cost | Lower | Higher |

Suitability for Low Volumes | Better value | Less suitable |

Heating and Cooling Times | Faster | Slower |

Defect Rates | Lower | Higher |

Ease of Modification and Repair | Easier | Harder |

When you compare silicone mold vs steel mold, don’t forget about aluminum. It often gives you the best balance for low-volume manufacturing.

Cost and Lead Time Comparison (Cost and Lead Time)

Initial Investment: Setup and Tooling Costs

Silicone Mold: Lowest Cost, Fastest Lead Time

If you want to get started quickly, silicone molds are your best bet. You can usually have your first parts in just 5 to 7 days. The cost is low, too. Most silicone molds cost between $500 and $5,000 for a single cavity. If your part is bigger or more complex, the price can go up to $20,000. This makes silicone molds perfect for small batches or when you need to test a new idea fast.

Fastest setup (5–7 days)

Lowest upfront cost ($500–$5,000)

Great for up to 100 units

Aluminum Mold: Moderate Cost, Balanced Lead Time

Aluminum molds sit right in the middle. They cost more than silicone molds but less than steel. You can expect to pay between $3,000 and $50,000, depending on how simple or complex your part is. Aluminum molds also have a balanced lead time, so you won’t wait as long as you would for steel.

Moderate setup time

Cost ranges from $3,000 to $50,000

Good for small to medium runs

Steel Mold: Highest Cost, Longest Lead Time

Steel molds take the most time and money to make. You might wait several weeks or even months. The price can start at $50,000 and go over $80,000 for complex shapes. Steel molds work best when you plan to make a lot of parts and need the mold to last a long time.

Longest setup (weeks to months)

Highest upfront cost ($50,000+)

Best for mass production

Per-Part Cost: The Long-Term View

When you look at the cost per part, things change as you make more pieces. The price of the mold spreads out over every part you make. This is why the right choice depends on how many parts you need.

Silicone Mold: High Part Cost Due to Labor and Depreciation

Silicone molds are great for prototypes and small runs, but they wear out fast. You’ll pay more per part because you need to replace the mold often and each part takes more labor. This makes them less cost-effective if you need hundreds or thousands of parts.

Steel Mold: Extremely Low Part Cost Due to Automation and Longevity

Steel molds cost a lot at first, but they last for tens of thousands of parts. As you make more, your per-part cost drops way down. Steel molds also work well with automated machines, which saves even more money over time. If you plan to scale up, steel molds give you the lowest cost per part in the long run.

Tip: The biggest factors that affect your per-part cost are the material you choose, how complex your mold is, how many parts you make, and how fast you can make them.

Here’s a quick table to help you compare:

Mold Type | Upfront Cost | Lead Time | Best For | Per-Part Cost (Low Volume) | Per-Part Cost (High Volume) |

|---|---|---|---|---|---|

Silicone | $500–$5,000 | 5–7 days | Prototypes, small runs | High | Not suitable |

Aluminum | $3,000–$50,000 | 2–4 weeks | Small/medium batches | Moderate | Moderate |

Steel | $50,000+ | 4–8 weeks+ | Mass production | High (at first) | Lowest |

When you compare silicone mold vs steel mold for low-volume manufacturing, think about how many parts you need now and in the future. The right choice saves you time and money.

Durability, Lifespan, and Volume Thresholds (Lifespan and Quantity)

Silicone Mold Longevity (Typical Output: 15-25 Shots)

Silicone molds work fast but do not last long. Most silicone molds make 25 to 50 parts before you need a new mold. If your design is easy and you use good platinum silicone, you might get more than 50 parts. Hard shapes usually give you only 20 to 25 good pieces.

Factors Limiting Silicone Mold Life Cycle (Heat and Tearing)

Many things can make a silicone mold wear out faster:

How well the operator works affects how many parts you get.

Silicone molds can squish under their own weight, so big parts may not be exact.

Each time you take out a part, the mold loses detail.

Silicone bends and stretches when you cast, so results can change.

The mold gets softer and tears more easily after many uses.

Acids, alkalis, and old age can break down silicone, especially with too much silicone oil.

Using too much silicone oil makes the mold weak, so it fails sooner.

Aluminum Mold Durability (Typical Output: 5,000 to 50,000 Shots)

Aluminum molds last much longer than silicone molds. You can make 5,000 to 50,000 parts with one aluminum mold. Aluminum molds are good for low-volume jobs because they balance cost and strength.

Best Use Cases for Aluminum Molds

Here is a table that shows when aluminum molds work best:

Use Case | Description |

|---|---|

Rapid Prototyping | Light and good at moving heat for quick tests |

Small-Volume Production Runs | Lower cost for tools and fast turnaround |

Mass Production Testing | Good for up to 100,000 parts before you switch to steel molds |

You might pick aluminum molds if you want to save money, keep tool costs low, or test your design before making lots of parts.

Steel Mold Durability (Typical Output: 100,000+ Shots)

Steel molds last the longest. You can make over 100,000 parts with one steel mold. Some steel molds can make more than a million parts. If you want to make lots of parts, steel molds are the best choice.

Types of Steel (P20 vs H13) and Their Durability

Let’s look at two kinds of steel:

Steel Type | Hardness (HRC) | Suitable Applications | Durability | Cost |

|---|---|---|---|---|

P20 | 30-36 | Good for small to medium jobs, soft plastics | Moderate | Cheaper at first |

H13 | 48-52 | Good for big jobs, hot and rough materials | High | Costs more |

If you use P20 steel, you spend less at first, but it wears out faster with tough plastics. H13 steel costs more because it needs heat treatment, but it handles heat and pressure better. One customer used P20 for polycarbonate parts, but after 50,000 parts, the mold wore out. They switched to H13, which lasted longer and saved time.

When you compare silicone mold vs steel mold for low-volume jobs, think about how many parts you need and how strong your material is. Picking the right mold helps you avoid delays and extra costs.

Critical Technical Differences (Key technology differences)

Precision and Tolerance Achievable

Silicone Mold Tolerance Limitations (Dimensional Instability)

Silicone molds are flexible but not very exact. They can make tricky shapes, but sometimes they stretch or move. This means your parts might be a little different each time. The size can change by about ±0.2mm. This is okay for testing, but not for perfect fits.

Steel Mold: Superior Precision for Tight Tolerances

Steel molds are much more exact. They can keep sizes as close as ±0.01mm. If you need parts that fit together tightly, steel molds are best. Every piece will look and fit the same. Here’s a table to show the difference:

Material | Precision Level | Tolerance Level | Application Areas |

|---|---|---|---|

Silicone | Moderate | Low | Prototyping, low-volume production |

Steel | Very High | Very Tight | Long-term production, high durability |

Surface Finish and Texturing

Silicone Mold Finish: Limited to Polished or Textured Master Pattern

Silicone molds copy the finish from the master pattern. You can polish or add simple textures to the master. If you want special looks, you must paint or coat the parts. These extra steps work for small batches but do not last long.

Steel Mold Finish: Directly Machined Textures (VDI, EDM)

Steel molds can have detailed textures made right in the mold. You can use VDI or EDM to add patterns or logos. This gives you more ways to make your parts look cool. Every part comes out looking sharp and the same.

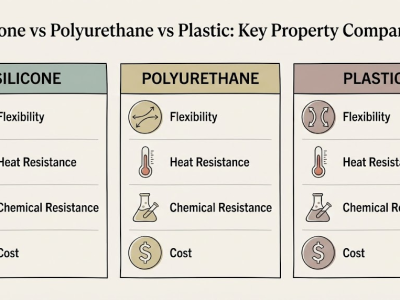

Material Compatibility and Temperature Tolerance

Materials Restricted by Silicone (High-Temperature Resins)

Silicone molds cannot take high heat or tough plastics. If you use hot resins, the mold can break or lose shape. You also cannot use as many types of plastics. For more choices, you may need to use steel molds.

Why Steel is Required for Glass-Filled or Abrasive Materials

Steel molds are strong enough for glass-filled or rough materials. Softer molds like aluminum wear out fast with these plastics. Steel molds do not scratch or break easily. You can make thousands of parts with no trouble. This matters for low volume cnc machining when you need tough molds.

Tip: If you want strong parts and perfect sizes, steel molds are best for hard jobs and tricky plastics.

Decision Criteria: When to Switch

Volume Thresholds and Break-Even Analysis (The Tipping Point)

You want to know when to move from one mold type to another. The answer often comes down to how many parts you need and how much you want to spend. Break-even analysis helps you see when the cost per part drops enough to make switching worth it. For example, a medical device company started with CNC-machined aluminum housings at $45 each for 2,000 units. When demand jumped to 18,000 units a year, they switched to stamping and dropped the cost to $8 per part. You can use this kind of thinking for your own project.

Rule of Thumb: When to Switch from Silicone to Aluminum

If you need fewer than 100 parts, stick with silicone molds.

If you plan to make between 100 and 2,500 parts, aluminum molds start to make sense.

For low volume production, switching to aluminum helps you save money and get better results.

Rule of Thumb: When to Switch from Aluminum to Steel

If your run goes past 10,000 parts, steel molds become the smart choice.

High-volume jobs (over 50,000 units) almost always need steel molds for durability and cost savings.

Tip: Low-volume manufacturing usually means 1–10,000 units a year. High-volume methods like injection molding or stamping work best above 50,000 units.

Product Requirements as the Primary Driver

Switching due to Required Tolerance and Finish

You might need to switch molds if your parts must fit together perfectly or look a certain way. Silicone molds work for simple shapes, but steel molds give you tight tolerances and sharp finishes. If you make custom shaped plastic parts that need to snap together or look polished, steel molds are the way to go.

Switching due to Material Selection (e.g., High-performance Plastics)

Some plastics need high heat or have glass fibers inside. Silicone molds cannot handle these materials. Steel molds let you use tough plastics and keep your parts strong. If you want to use high-performance plastics, you should switch to steel.

Timeline and Iteration Needs

You may want to test your design quickly or change it often. Silicone molds help you move fast and try new ideas. Aluminum and steel molds take longer to make, but they last much longer. If you need speed and lots of changes, silicone molds are best. If you want to make thousands of parts with the same design, choose aluminum or steel. Low volume cnc machining also helps when you need quick changes for small batches.

Remember: When you compare silicone mold vs steel mold, think about your timeline, budget, and the number of parts you need. The right choice makes your project easier and saves you money.

Real-World Switching Examples (Case Analysis)

Example 1: Startup Launch Scenario (Switching from Silicone to Aluminum)

Imagine you just launched a new product. You need to test your idea and get feedback fast. You start with silicone molds because they are quick and cheap. You can make changes easily and get your first samples in days. After you show your product to customers, you get more orders. Now, you need to make a few hundred parts. Silicone molds wear out too quickly, so you switch to aluminum molds.

Here’s what you gain when you make the switch:

Faster cycle times for each part.

Lower cost per part as you make more pieces.

Better consistency in size and shape.

In one case, an engineer saved $57,000 a year by switching production methods early. They looked at manufacturability and found a better way to make parts. You can learn from this by checking your design and production plan before you invest too much.

You also find that adjusting simple features, like corner shapes, can make your parts easier to produce. Simplifying your design helps you save money and avoid big machines.

Example 2: Scaling Up Production (Switching from Aluminum to Steel)

Your business grows. Orders jump from hundreds to thousands. You notice aluminum molds start to wear out. You need more durability and better quality. You decide to switch to steel molds.

Why do manufacturers make this move?

Steel molds last much longer than aluminum molds.

You can produce millions of parts with the same mold.

Steel molds handle tough materials, like glass-filled plastics.

The upfront cost is higher, but you save money over time.

Steel molds also let you use high-temperature resins and abrasive materials. You get consistent quality for every part. If you use low volume cnc machining, you can test designs before investing in steel molds.

Early evaluation of your production needs helps you avoid costly mistakes. You can reduce cycle times and overhead by simplifying your part design.

Conclusion: Making the Right Tooling Investment

Choosing the right mold for your project can feel overwhelming. You want to save money, move fast, and get the best results. The good news? You have clear options. If you need only a few parts or want to test a new idea, silicone molds help you start quickly. They cost less and let you make changes without much trouble.

When your orders grow, you might see that silicone molds wear out too soon. That’s when aluminum molds step in. They last longer and give you better quality. You can use them for hundreds or even thousands of parts. If your business keeps growing, steel molds become the smart choice. They handle big jobs and tough materials. You get the lowest cost per part when you make lots of pieces.

Here’s a simple checklist to help you decide:

How many parts do you need?

Do your parts need to fit together perfectly?

What kind of plastic or resin will you use?

How fast do you need your first parts?

Will you change your design often?

Tip: Talk to a mold expert before you invest. They can help you avoid mistakes and pick the best option for your needs.

You can also make a table to compare your choices. Write down the cost, lead time, and how many parts each mold can make. This helps you see the best fit for your project.

Low-volume manufacturing gives you the freedom to test ideas and grow at your own pace. When you match your mold to your needs, you save time and money. Take a moment to review your project goals. The right tooling investment sets you up for success.

When you choose between silicone and steel molds, think about your production volume, budget, and part requirements. For low-volume manufacturing, matching your mold type to your needs saves you time and money. Before you start, use a checklist to review key points:

Work with different teams to cover all mold design details.

Check your tool design for errors and manufacturability.

Use DFM principles to make your process smoother.

Talk to experts if you feel unsure. Take time to look at your current and future needs.

FAQ

How do I know if silicone molds are right for my project?

If you need fewer than 100 parts and want to test your design quickly, silicone molds work best. You get fast results and can change your design easily. They save you money for small batches.

Can I use steel molds for prototypes?

You can use steel molds, but they cost more and take longer to make. For prototypes, silicone or aluminum molds help you move faster and spend less. Steel molds fit best when you need thousands of parts.

What materials can I use with silicone molds?

Silicone molds work with many plastics and resins. You should avoid high-temperature or abrasive materials. These can damage the mold quickly. For tough plastics, steel molds give you better results.

How much does it cost to switch from silicone to steel molds?

Switching costs depend on your part size and design. Silicone molds start at $500. Steel molds can cost $50,000 or more. You save money with steel molds if you plan to make thousands of parts.

LKprototype

LKprototype