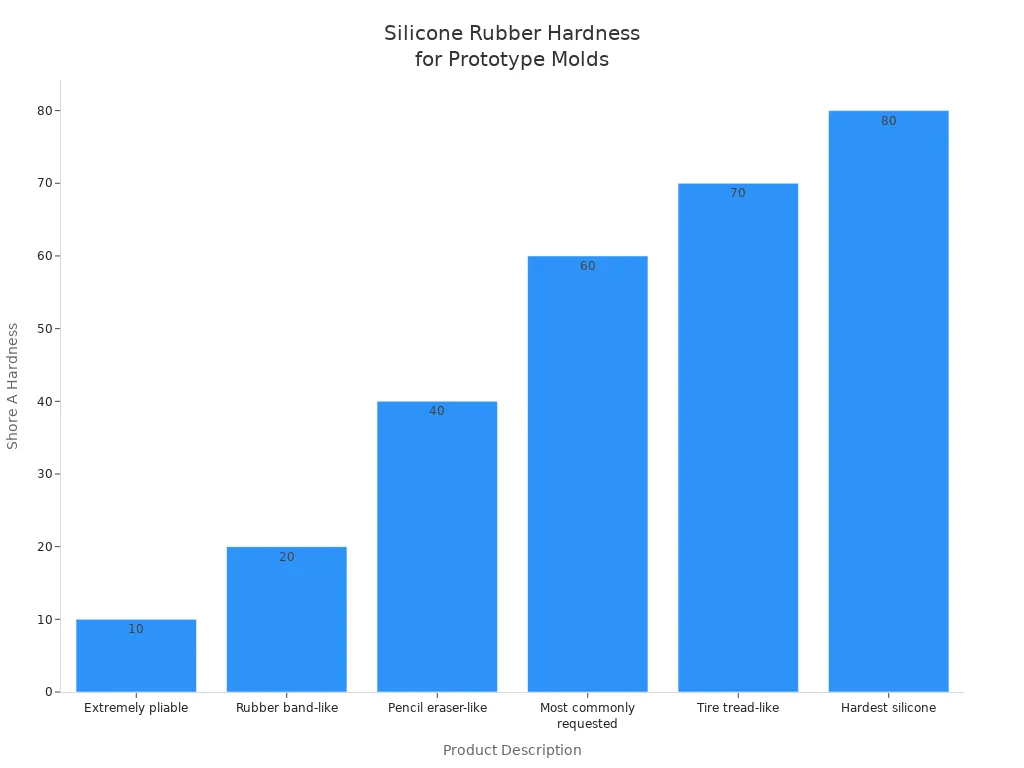

When you pick the best silicone for prototype molds, Shore A hardness is important. Shore A shows how soft or hard the silicone feels. It goes from very bendy to very stiff. This scale helps you choose a silicone that fits your project. Softer silicone is good for tiny details. Harder silicone lasts longer when used a lot.

Here is a quick look at common Shore A values:

Shore A Hardness | Description |

|---|---|

10° | Very bendy, for special uses |

20° | Soft, like a rubber band |

40° | Bendy, like a pencil eraser |

60° | Good for tubes and gaskets |

70° | Tough, like tire tread |

80° | Hard, can take the place of plastic |

You can find top products like AeroMarine, Mold Max 30, Platinum silicone, Alumilite, Smooth-On, PURE MOLD, SiliNOT!, and Dental Polysiloxane. These choices have different strengths and detail levels. This makes it easier to pick the right silicone for your prototype molds.

Key Takeaways

Learn about Shore A hardness to pick the right silicone. Softer silicone (10-20) works best for molds with lots of details. Harder silicone (30+) is better if you want it to last longer.

Choose between platinum cure and tin cure silicone for your project. Platinum cure is safer and lasts longer. Tin cure costs less and is good for easy jobs.

Match the Shore A hardness to how complex your part is. Use low Shore A for shapes with lots of small details. Use high Shore A for simple and strong molds.

Always look at the product label for Shore A ratings. This helps you pick silicone that fits your project needs.

Follow the right steps for mixing and curing. Use a vacuum chamber to get rid of air bubbles. This helps your mold turn out smooth.

Shore A Hardness Explained: The Foundation of Silicone Selection

What Is Shore A Hardness? (Definition and Measurement Scale)

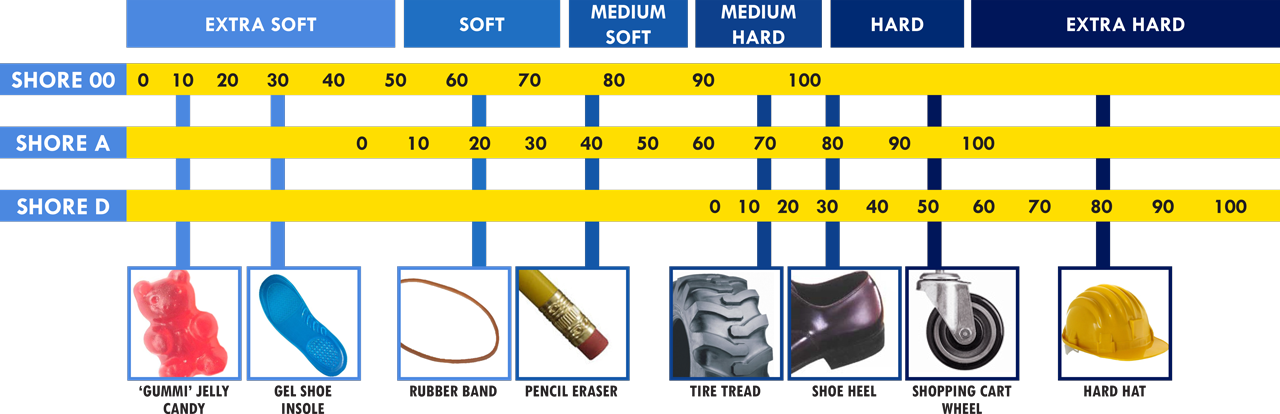

You need to understand Shore A hardness before you choose the best silicone for prototype molds. Shore A hardness tells you how much a material resists indentation. This scale helps you know if the silicone feels soft or hard. Albert F. Shore created this scale for elastomers like silicone rubber. The Shore A scale goes from 0 to 100. A higher number means the material is harder.

The Shore A hardness scale measures resistance to indentation.

It works best for elastomers such as silicone rubber.

The scale ranges from 0 (very soft) to 100 (very hard).

You measure Shore A hardness with a durometer. This tool presses a spring-loaded steel rod into the silicone and checks how deep it goes.

If you want to make a mold with fine details, you should look for a lower Shore A value. If you need a mold that lasts longer and resists wear, you should pick a higher Shore A value.

Tip: Always check the Shore A rating on the product label. This number helps you match the silicone to your project needs.

Why Shore A Matters for Prototype Molds

Shore A and Dimensional Stability

You want your mold to keep its shape after many uses. Silicone with a higher Shore A hardness holds its form better. This means your prototype parts will look the same every time you cast them. Softer silicone may stretch or deform, which can change the size of your parts.

Shore A and Tear/Tensile Strength

Tear and tensile strength matter when you remove parts from the mold. Silicone with a medium to high Shore A rating resists tearing. This helps your mold last longer. If you use a very soft silicone, you might see rips or tears after several uses. You should always balance flexibility and strength when you select the best silicone for prototype molds.

The Crucial Decision: Platinum Cure vs. Tin Cure Silicone

When you pick silicone for prototype molds, you must choose between platinum cure and tin cure. Each type has its own good and bad points. Knowing these differences helps you choose the right silicone for your project.

Platinum Cure (Addition Cure): Pros, Cons, and Best Use

Platinum cure silicone uses platinum to help it set. It does not make any extra chemicals when it cures. This kind is safe for skin and food. Platinum cure silicone is best for molds that need lots of detail and last a long time.

Feature | Platinum Cure Silicone | Tin Cure Silicone |

|---|---|---|

Curing Mechanism | Addition Cure (no byproducts) | Condensation Cure (byproducts released) |

Safety | Generally skin-safe and food-safe | Not considered skin-safe |

Byproducts | None | Alcohol and other compounds |

Key Advantages: Low Shrinkage and FDA Compliance

Platinum cure silicone almost never shrinks. Your molds keep their shape and details. Many platinum cure silicones meet FDA rules. You can use them for food or skin. They also stand up to heat and last a long time.

Tip: Pick platinum cure silicone for molds you want to keep or when you need very exact shapes.

The Risk of Cure Inhibition (Troubleshooting)

Platinum cure silicone can have trouble with some materials. If you use sulfur, amines, or latex, it may not cure right. Always clean your tools and space to stop this problem. Sticky spots mean cure inhibition happened.

Tin Cure (Condensation Cure): Pros, Cons, and Best Use

Tin cure silicone uses tin to help it set. It makes extra chemicals, like alcohol, when it cures. Tin cure silicone costs less and is simple to use for many jobs.

Aspect | Tin Cure Silicone Rubber | Platinum Cure Silicone Rubber |

|---|---|---|

Cost | Less expensive | More expensive |

Ease of Use | Easier to use | More sensitive to inhibition |

Flexibility | Good flexibility | Exceptional heat resistance |

Shrinkage | Slight shrinkage (~0.3%) | Low shrinkage (~0.1%) |

Shelf Life | Shorter shelf life | Longer shelf life |

FDA Compliance | Not FDA compliant for food or skin | FDA compliant for food and skin applications |

Key Advantages: Cost-Effectiveness and Resistance to Inhibition

Tin cure silicone saves you money. It does not have cure problems with most materials. Tin cure silicone is good for easy, short-term molds.

Drawbacks: Higher Shrinkage and Limited Lifespan

Tin cure silicone molds can shrink a bit. This can change small details. These molds do not last as long as platinum cure molds. They also do not handle heat as well. Do not use tin cure silicone for food or skin.

Choosing Shore A Hardness Based on Application

Matching Shore A to Part Complexity (Geometry)

When you make a prototype mold, think about the shape. The Shore A hardness you pick changes how easy it is to take out the part. It also affects how long your mold will last.

Low Shore A (5A-15A): Ideal for Parts with Deep Undercuts and High Flexibility

If your part has deep undercuts or tricky shapes, use soft silicone. Soft silicone bends a lot. This helps you pull out hard parts without breaking them. Shore A values from 15 to 25 work for small details or deep undercuts. Softer silicone makes it simple to remove parts and keeps details safe.

Soft silicone (15-25A) is best for hard shapes.

Flexible molds stop small pieces from tearing.

Use low Shore A for jewelry, figurines, or curvy parts.

Medium Shore A (20A-30A): The Versatile Choice for Standard Prototypes

Medium Shore A silicone is a good middle choice. It bends enough for most shapes but is strong for many uses. Use it for regular prototypes that are not too detailed.

Medium hardness (20-30A) fits most needs.

You get strong molds and easy removal.

Many people use this range for molding.

High Shore A (30A+): When Rigidity is Key (Simple Shapes)

If your part is simple and you want a stiff mold, pick a high Shore A. Hard silicone does not wear out fast and keeps its shape. Use this for blocks, discs, or basic parts.

High Shore A (30A+) gives stiff, strong molds.

Best for parts that do not need to bend.

Matching Shore A to Casting Material (Mold Longevity)

The stuff you pour into your mold matters too. Some materials need a tougher mold to last longer.

Casting Rigid PU Resins (Requires Higher Shore A to Resist Wear)

If you use rigid polyurethane resin, you need a tough mold. A higher Shore A stops the mold from wearing out. Pick silicone in the 40-50A range for a good mix of bend and strength.

Tip: Harder silicone molds last longer with tough materials.

Casting Wax or Low-Temp Metals (Less Demanding)

Wax and low-temp metals are easy on molds. You can use softer silicone for these. The Shore A scale helps you pick the right softness. Softer molds work well and make it easy to take out parts.

Casting Material | Recommended Shore A Hardness | Mold Longevity |

|---|---|---|

Rigid PU Resin | 40-50A | High |

Wax/Low-Temp Metals | 15-25A | Moderate |

When you match Shore A hardness to your part and material, you get the best silicone. This helps your mold last longer and makes your project easier.

Best Silicone Shortlist and Cost Factor [Incorporating Cost Considerations]

Top Product Recommendations (Based on Shore A and Cure Type)

There are many good choices for silicone for prototype molds. Each product has a different Shore A hardness and cure type. Here are some top picks:

AeroMarine 128 Tin Cure: Shore A 30, works well for simple shapes and fast jobs.

Smooth-On Mold Max 30: Tin cure, Shore A 30, good for most prototypes.

Alumilite High Strength 3: Tin cure, Shore A 15, best for tricky shapes and flexible molds.

Smooth-On Dragon Skin: Platinum cure, Shore A 10-20, great for tiny details and safe for skin.

PURE MOLD Platinum Silicone: Shore A 25-35, lasts a long time and does not shrink much.

SiliNOT! Platinum Cure: Shore A 20, good for food-safe and medical molds.

Dental Polysiloxane: Platinum cure, Shore A 20-30, used for exact dental models.

Tip: Pick the Shore A value and cure type that fit your project. This helps you get the best results.

Material Cost Comparison (Platinum vs. Tin Cure Price Difference)

Cost is important when you choose silicone. Platinum cure silicone costs more but lasts much longer. Tin cure silicone is cheaper but does not last as long.

Type | Price Range | Average Lifespan |

|---|---|---|

Tin Cure Silicone Rubber | $36.40 to $125.52 | 1 to 5 years |

Platinum Cure Silicone Rubber | $53.00 to $1,280.00 | 30 to 45 years |

Silicone molds are strong, accurate, and can be used in many ways, but they cost more.

The price depends on the material, how long it takes to make, and the skill needed.

Pros and Cons of Key Silicone Features

It is smart to know the main features before you pick. Here are some important things:

Handles heat up to 305°C and stays flexible at -100°C.

Very strong and lasts a long time.

Does not get damaged by UV, flames, or chemicals.

Great for keeping water out and sealing things.

Works well for hard shapes and deep undercuts.

Safe to use and often meets FDA rules.

But remember:

Silicone costs more than other types of rubber.

It can tear easier than some other elastomers.

Some oils and fuels can make it swell.

Needs special steps to stick to some surfaces.

If you want the best silicone for prototype molds, think about cost, how long it will last, and which features matter most for your project.

Advanced Application Tips and Troubleshooting

Proper Mixing, Measuring, and Vacuum Degassing

You want your silicone mold to be strong and smooth. First, measure each part with a digital scale. Use a clean bucket for mixing. Add the activator to the base. Stir until the color looks the same. This stops weak spots from forming.

Put the mixed silicone in a vacuum chamber. Let it sit for five minutes. This step removes trapped air. Air bubbles can make weak spots and ruin the mold’s surface. When pouring, start at one corner and pour slowly. Pouring from the bottom up pushes out bubbles.

Techniques to Minimize Bubbles/Voids

Mix slowly so you do not add air.

Use a vacuum chamber to remove bubbles.

Pour silicone in a thin stream from one spot.

Tap the mold box gently to help bubbles rise.

Aspect | Impact of Improper Mixing/Degassing |

|---|---|

Physical Properties | Weakens strength and oil resistance |

Surface Quality | Causes surface defects and poor finish |

Mechanical Strength | Lowers the mold’s durability |

Aging Resistance | Reduces how long the mold lasts |

Integrity of Molds | Air bubbles hurt the mold’s shape and detail |

Curing Time Variables and Post-Cure Processes

Curing time changes based on a few things. More cross-linking agent makes curing faster. Warmer temperatures also speed up curing. Different curing methods change how long it takes.

Factor | Description |

|---|---|

Concentration of cross-linking agent | More agent means faster curing. |

Curing temperature | Higher heat makes silicone cure quicker. |

Curing method | Some methods work faster than others. |

Post-curing helps make the silicone stable. It removes leftover chemicals. This makes the mold safer for food use. Post-curing also helps the mold keep its shape over time.

Troubleshooting Common Mold-Making Issues

Problem | Solution |

|---|---|

Bubbles in Silicone Mold | Mix well and use vacuum degassing. |

Apply a thin, even coat of mold release agent. | |

Incomplete Curing | Follow the correct mixing ratios and curing times. |

Surface Imperfections | Keep the mold clean and use release agents. |

Tearing or Ripping of Mold | Use high-quality silicone for better durability. |

Dealing with Cure Inhibition (Contamination)

You can stop cure inhibition by using UV-set silicones or tin-catalyzed systems. These choices avoid problems with platinum-catalyzed silicone. Always keep your workspace clean. Stay away from sulfur or latex.

Fixing Dimensional Instability (Shrinkage)

Try post-curing your mold to help stability. UV-set silicones and fast crosslinking methods, like thiol–ene chemistry, help keep the mold’s shape. These steps lower shrinkage and help your mold last longer.

Ultimate Comparison Table for Decision Making

Product, Cure Type, Shore A, Cost, and Lifespan Summary

If you want the best silicone rubber for your prototype molds, you need to compare a few things. Look at Shore A hardness, cure type, cost, and how long it lasts. The table below shows these differences so you can see them quickly.

Product Name | Cure Type | Shore A Hardness | Cost Range | Lifespan | Flexibility | Detail Capture | Durability |

|---|---|---|---|---|---|---|---|

AeroMarine 128 | Tin Cure | 30 | $36 - $125 | 1-5 years | Moderate | Good | Very Good |

Mold Max 30 | Tin Cure | 30 | $40 - $130 | 1-5 years | Moderate | Good | Very Good |

Alumilite High Strength 3 | Tin Cure | 15 | $45 - $140 | 1-5 years | High | Excellent | Moderate |

Smooth-On Dragon Skin | Platinum Cure | 10-20 | $53 - $200 | 30-45 years | High | Excellent | Good |

PURE MOLD Platinum Silicone | Platinum Cure | 25-35 | $60 - $250 | 30-45 years | Moderate | Very Good | Very Good |

SiliNOT! Platinum Cure | Platinum Cure | 20 | $70 - $300 | 30-45 years | Moderate | Very Good | Good |

Dental Polysiloxane | Platinum Cure | 20-30 | $80 - $400 | 30-45 years | Moderate | Very Good | Very Good |

Tip: Pick a lower Shore A value like 10 or 15 if you want your mold to bend a lot and show tiny details. If you want your mold to last longer, choose platinum cure silicone with Shore A 25 or higher.

When you look at silicone rubbers, do not just check the hardness and price. You want a product that works well for your project and gives good results. Here are some things to think about:

Product quality: It should always work the same way and be easy to use. Good silicone means fewer mold problems.

Range of offerings: There are many types for different jobs, from small details to big molds.

Pricing and value: Make sure the price is fair for what you get. Think about how much you spend over time.

Customer support: Help and training can make your project go smoother.

Innovation: New types and eco-friendly choices help you do better work.

Supply chain reliability: Fast shipping and having products in stock stop you from waiting.

Certifications: Safety and green rules are important for some projects.

User feedback: Reviews and stories from other people show how the silicone works.

You can find good brands like Dow Corning, Momentive, Shin-Etsu Chemical, Wacker Chemie, Rubbercraft, SILICONE SOLUTIONS, KCC Corporation, and Bluestar Silicones. These companies make silicone rubbers you can trust for many mold-making jobs.

If you look at all these things, you will pick the right silicone rubber. This helps you get better results and save both time and money.

You can pick the best silicone for your mold by matching Shore A hardness to your project. Most prototype molds need Shore A between 0 and 30. This range is good for small details and bending. If you need a mold for tough jobs, use Shore A from 70 to 90.

Shore A Hardness Range | Application Type |

|---|---|

0-30 | Best for detailed molds and flexibility |

70-90 | Good for strong molds in hard jobs |

When you pick silicone, think about how fast you need it, how much it costs, and how close the mold is to your final part. To get better molds, follow these expert tips:

Step/Consideration | Description |

|---|---|

Reproduction Accuracy | Silicone rubber shows tiny details, so it is great for prototype molds. |

Preventing Inhibition | Use a barrier spray to stop curing problems. |

Resistance to Inhibition | Choose silicone that does not get ruined by master part chemicals. |

Make sure your mold shows all the details.

Use a barrier spray if you need it.

Pick silicone that works with your casting material.

Now you can choose and use silicone rubber without worry.

FAQ

What does Shore A mean for silicone molds?

Shore A measures how hard or soft silicone feels. You use this scale to pick the right silicone for your mold. Lower numbers mean softer silicone. Higher numbers mean harder silicone.

How do you stop bubbles in silicone molds?

You mix slowly and use a vacuum chamber. Pour silicone in a thin stream from one spot. Tap the mold box gently. These steps help you get smooth molds.

Tip: Always measure your silicone parts with a digital scale for best results.

Can you use platinum cure silicone for food molds?

Yes, you can use platinum cure silicone for food molds. Many brands meet FDA rules. Always check the product label for food safety before you start.

Silicone Type | Food Safe? |

|---|---|

Platinum Cure | ✅ |

Tin Cure | ❌ |

What is the best Shore A for detailed prototype molds?

You get the best detail with Shore A between 10 and 20. Softer silicone shows tiny features. Use this range for jewelry, figurines, or parts with deep undercuts.

LKprototype

LKprototype