The manufacturing process means changing raw materials into products people can use. Manufacturing is very important for all industries. Factories and workers take materials, make parts, and build things people need every day. Manufacturing turns simple things into complex items like cars, phones, and furniture. People need manufacturing for jobs, new ideas, and a strong economy. Each type of manufacturing has its own steps and tools. Learning about manufacturing helps people see how products get to stores. Today, technology gives new machines and ideas to manufacturing, making things faster and smarter.

Key Takeaways

Manufacturing turns raw materials into useful products by using many steps.

There are different types of manufacturing for different products. Some make many items at once, and some make special items.

Good planning, checking quality, and working together help make safe and good products.

Today, factories use robots and smart machines to work faster and safer. They also help make less waste.

Sustainable manufacturing helps the environment by saving energy and recycling materials.

Manufacturing Process

Definition

The manufacturing process is a group of steps. These steps change raw materials into finished products. People in factories use tools and machines to make things. Each step in manufacturing has a special job. Some steps shape metal. Other steps connect parts together. The manufacturing process can have many steps. These steps include cutting, forming, or putting things together. All these steps help turn simple materials into useful products.

Manufacturing processes are not always the same. Each factory can use a different process. Some factories use process manufacturing. This makes a lot of the same product, like food or chemicals. Other factories use discrete manufacturing. This makes things like cars or computers. The process a factory uses depends on what they make and what the company needs.

Note: Picking the right manufacturing process helps companies work faster and make better products.

Importance

Manufacturing is very important in the world. It gives people jobs and helps make new products. Manufacturing also helps the economy grow. The manufacturing process lets companies turn ideas into real things. Without strong manufacturing, people would not have many products they use every day.

Production processes help companies give customers what they want. They also help lower costs and make better products. When companies use the best methods, they can make more things in less time. This helps them do better than other companies.

Manufacturing processes also help with new ideas. New machines and better ways of working help companies make new products. Many industries, like cars, electronics, and food, need good production processes.

Here are some reasons why the manufacturing process is important:

It gives people jobs in many places.

It helps other industries by making parts and tools.

It helps companies grow and do well.

It brings new products to people everywhere.

Manufacturing processes change how people live and work. They help turn ideas into real things and keep the world moving forward.

Manufacturing Process Types

Manufacturing industries use different process types to make things. Each process works for certain needs and product designs. Companies pick a process based on what they make and how many they need. The process also depends on how hard the product is to make. Here are the main types of manufacturing processes used today.

Repetitive Manufacturing

Repetitive manufacturing uses the same steps again and again. Workers and machines do the same jobs many times. This process is good for products that do not change much. It is best when companies need to make a lot of the same thing. Car factories use this process to build many cars each month. Companies that make electronics, like TVs, use it too. Repetitive manufacturing helps lower costs and keeps quality the same.

Tip: Repetitive manufacturing works best for products that stay the same and are needed in large numbers.

Discrete Manufacturing

Discrete manufacturing makes products one by one. Each item can be different from the others. This process lets companies change the design or features. Factories that build computers or airplanes use discrete manufacturing. Workers may use different tools or machines for each product. Discrete manufacturing is good for companies that need to make many types of things.

Example: A company can build custom computers for each customer. Each computer can have different parts or features.

Job Shop Manufacturing

Job shop manufacturing makes small groups of custom products. Each order may need special steps or tools. Workers move products between different machines. This process is good for companies that make unique or hard items. Machine shops and tool makers use job shop manufacturing. It gives high flexibility but can take more time.

Example: A shop may make custom metal parts for a special machine. Each part can have a different shape or size.

Batch Process Manufacturing

Batch process manufacturing makes products in groups called batches. Workers set up machines for one batch, then change them for the next. This process works well for things like food, paint, or chemicals. Companies can make different flavors or colors in each batch. Batch process manufacturing helps manage different products and changing needs.

Example: A bakery may bake one batch of bread, then make a batch of cookies.

Continuous Process Manufacturing

Continuous process manufacturing runs all the time without stopping. Raw materials move through machines in a steady flow. This process is good for products that need the same steps every time. Oil refineries and paper mills use continuous process manufacturing. It works best for making a lot of the same product.

Example: A factory may run a machine that makes plastic sheets all day and night.

Additive Manufacturing

Additive manufacturing builds products by adding layers of material. This process uses digital designs and special machines like 3D printers. Additive manufacturing lets companies make complex shapes and custom items. Industries use it for prototypes, medical implants, and small runs. Additive manufacturing cuts down on waste and speeds up making new products.

Example: A company can use a 3D printer to make a custom part for a car engine.

Note: Additive manufacturing is changing how companies design and make products, especially for special or complex items.

How Product Complexity Influences the Choice of Manufacturing Process

Product complexity is important when picking a manufacturing process. When products have many parts or special features, companies need flexible processes. More product types mean workers and machines must handle changes. Complex products often need special machines and more checks for quality.

Companies face challenges like:

Sharing work between machines and workers

Making machines do many jobs

Adding more steps to check quality

Handling more data and changes

Manufacturing systems must change to meet these challenges. Some companies use flexible systems or modular designs for complex products. Others use scheduling or wait to finish products until later. These choices help control costs, keep quality high, and deliver on time.

Companies that make many different products often use job shop or discrete manufacturing. Companies that make simple, high-volume items may use repetitive or continuous process manufacturing.

There is a trade-off between product variety and performance. More complex products can slow down production and raise costs. They can also make quality harder to control. Manufacturing industries must balance being flexible and working efficiently when choosing a process.

Common Manufacturing Methods

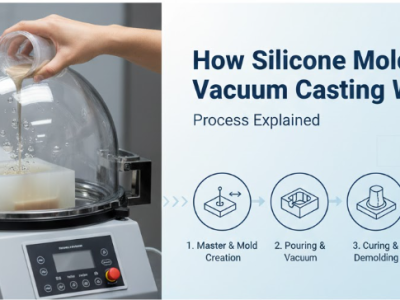

Casting

Casting makes shapes by pouring liquid metal or plastic into a mold. The liquid cools and gets hard in the mold. Many companies use casting for tricky parts. This method works well in batch process manufacturing and continuous process manufacturing. Factories use casting for engine blocks and machine parts. Casting can help companies save weight and money. The table below shows how casting helps different industries:

Company Type | Component | Weight Reduction | Cost Reduction |

|---|---|---|---|

Aerospace | Critical engine part | 25% | 30% |

Automotive | Engine block | 15% | 20% |

Molding

Molding shapes things by putting material inside a mold. Workers use molding for plastics, rubber, and some metals. This method is used in repetitive manufacturing and batch process manufacturing. Toy makers and bottle companies use molding to make many of the same thing.

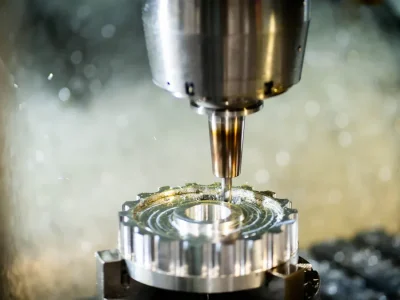

Forming

Forming changes the shape of materials without cutting anything away. Workers use force to bend, stretch, or press metal sheets. Forming is used in making cars and appliances. This method works in repetitive manufacturing and discrete manufacturing.

Joining

Joining puts two or more parts together. Workers use welding, soldering, or glue. Joining is important for making cars, electronics, and furniture. This method is used in discrete manufacturing and job shop manufacturing.

Plating

Plating covers something with a thin layer of metal. Factories use plating to stop rust or make things look better. Jewelry, electronics, and car parts often need plating. This method is used in batch process manufacturing and job shop manufacturing.

Extrusion

Extrusion pushes material through a shaped hole to make long objects. Factories use extrusion for pipes, rods, and window frames. This method is common in continuous process manufacturing and repetitive manufacturing.

Injection Molding

Injection molding pushes melted material into a mold. The material cools and becomes solid. Factories use injection molding for plastic parts in toys, electronics, and packaging. This method is used in repetitive manufacturing and batch process manufacturing.

Blow Molding

Blow molding makes hollow plastic things by blowing air into hot plastic. Factories use blow molding for bottles and containers. This method is popular in repetitive manufacturing.

Thermoforming

Thermoforming heats plastic sheets and shapes them over a mold. Factories use thermoforming for packaging, trays, and panels. This method is used in batch process manufacturing and repetitive manufacturing.

Rotational Molding

Rotational molding spins a mold while heating plastic inside. The plastic sticks to the mold and makes hollow things. Factories use rotational molding for tanks, toys, and big containers. This method is used in batch process manufacturing and job shop manufacturing.

Note: Each manufacturing method works with different process types. Companies pick methods based on what they make, how many they need, and what material they use.

Production Steps

Planning

Planning is the first step in making things. Teams set goals for what they want to make. They decide how to use workers and machines. Teams make a plan for each step. Good planning helps pick the best way to make things. It also helps set up the work area. Teams plan for safety and good quality. They use schedules to make sure work happens on time. Careful planning helps save money and time.

Design and Conceptualization

Design and conceptualization help shape the product before making it. Engineers and designers draw pictures and make models. They think about how the product will look and work. This step helps teams choose the best way to make things. Good design helps keep products safe and high quality. Teams use computers to test ideas before building anything.

Material Selection and Procurement

Material selection and procurement bring the right materials to the factory. Teams pick materials that fit what the product needs. They check that materials are good quality. Teams order supplies and look for any problems. The right materials help work go smoothly. Teams watch supplies to stop delays and keep things moving fast.

Processing and Transformation

Processing and transformation turn raw materials into parts. Workers use machines to cut, shape, or form materials. This step uses many ways to make things. Teams work safely and check for good quality. The work moves from one station to the next. Doing this step well helps make more products faster.

Assembly and Construction

Assembly and construction put all the parts together. Workers or robots join, weld, or fasten pieces. The work must follow strict rules for quality. Teams check that each product is safe and works well. A good work area helps make things faster and with fewer mistakes.

Quality Control and Testing

Quality control and testing look for problems in each product. Teams use tests to make sure products are good. They follow plans to catch mistakes early. Good quality control keeps customers happy. It also helps the company do well. Teams use data to make the process better and faster.

Packaging and Distribution

Packaging and distribution get products ready to ship. Teams pack items to keep them safe. They label and sort products for easy delivery. Good planning helps stop slowdowns and fix problems fast. Using computer systems helps teams track products and keep things running well. These steps help products reach customers safely and on time.

Tip: Each step in making things builds on the last one. Good planning, strong quality checks, and fast work areas help companies make safe, high-quality products.

Modern Manufacturing Applications

Automation and Robotics

Factories use automation and robotics to speed up work and make it safer. Robots help by lifting heavy things and repeating jobs many times. Automation helps companies keep quality high and make fewer mistakes. Many factories use robots to check for problems in products. This makes work faster and keeps workers safe. Automation is also used in process manufacturing, where machines work for many hours without stopping. Food and beverage companies use robots to pack and sort items. This keeps things clean and follows safety rules.

Smart Manufacturing

Smart manufacturing uses new technology to link machines, computers, and people. Sensors gather data from each step of the process. Computers look at this data to find ways to work better and make good products. In food and beverage factories, smart manufacturing helps track every batch for safety. Factories use tools like AI and big data to know when machines need fixing. This means less downtime and keeps work going. The smart manufacturing market is growing quickly, showing how important this technology is now.

Smart manufacturing helps companies follow rules and improve how they work. It also helps them make better choices and improve their process.

Sustainable Manufacturing

Sustainable manufacturing tries to use less energy and make less waste. Companies pick materials that are better for the earth. They recycle and reuse parts when they can. Food and beverage factories use less water and energy to help the planet. These good habits help companies follow strict rules and laws. Advanced manufacturing helps by using new materials and better designs. This protects resources for the future.

Industry Examples

Many industries use advanced manufacturing to do better work. The pharmaceutical industry uses smart systems to check quality and follow rules. Food and beverage companies use process manufacturing to make safe products in big amounts. The table below shows how different industries use technology to work better and make good products:

Industry/Application Area | Example/Statistic | Benefit/Validation |

|---|---|---|

Quality Control | Automated Optical Inspection (AOI) systems for product checks | Reduces human error, improves product quality |

Predictive Maintenance | AI for machine repairs and checks | Increases uptime, reduces failures |

Industry 4.0 Technologies | IIoT and big data in food, pharmaceutical, and chemicals | Optimizes production and yield |

Market Growth Projection | Smart manufacturing market to reach $576.21 billion by 2028 | Shows strong growth and adoption |

Workforce Automation | 60% of jobs have tasks that can be automated | Improves efficiency and productivity |

Companies that use advanced manufacturing get better efficiency, higher quality, and stronger sustainability in their process manufacturing.

Manufacturing changes ideas into real things we use. People pick different manufacturing types for each product. Every step, like planning and packaging, helps keep things good. Modern factories use smart tools and machines to work better and waste less. Technology gives new ways to make food, cars, and electronics. Learning about manufacturing shows how things are made and why quality is important. As new ideas come, manufacturing will keep changing. Readers can learn more to see how making things affects their lives.

FAQ

What is the main goal of the manufacturing process?

The main goal is to change raw materials into finished products. Companies use many steps and tools to make things people need. This process gives people jobs and helps the economy grow.

How do companies choose the right manufacturing process?

Companies think about what kind of product they make. They look at how many they need and how hard it is to make. They also care about cost, speed, and quality. Picking the right process helps them work well and give customers what they want.

Why is quality control important in manufacturing?

Quality control checks products for any problems. It helps companies find mistakes early. Good quality control keeps customers happy and keeps the company’s good name.

How does automation help factories today?

Automation uses machines and robots to do jobs. It makes work go faster and keeps workers safe. Automation also helps keep products good and stops human mistakes.

What is sustainable manufacturing?

Sustainable manufacturing uses less energy and makes less waste. Companies pick better materials and recycle when they can. This helps protect the earth and follows important rules.

LKprototype

LKprototype