Curious about how iPhone prototypes shape the final product? This article gives you an exclusive look at rare iPhone prototypes, revealing how Apple’s secretive testing processes influence the features and design of their iconic devices, including the iPhone prototype.

Key Takeaways

Apple’s iPhone prototypes have evolved significantly, reflecting a continuous pursuit of innovation that shapes the design and functionality of final products.

The prototyping process involves meticulous stages of design, including the use of silicone molds and CNC technology, which ensure high precision and quality.

Recent trends in iPhone prototyping include the use of advanced materials and the integration of AI and machine learning, enhancing product durability and user experience.

The Evolution of iPhone Prototypes

Throughout its history, Apple has carefully developed a series of prototypes that have played a crucial role in shaping the design and capabilities of their final products. These prototype devices stand as a core component of Apple’s drive for innovation, exemplifying their continuous quest for excellence. The progression seen in iPhone prototypes demonstrates how dedicated Apple is to expanding the limits of both technology and aesthetics.

From the inception of the original iPhone to the most current iterations on offer today, these prototype devices have undergone significant transformations. They’ve integrated cutting-edge technologies along with sophisticated design elements that now serve as benchmarks within the smartphone industry. A closer inspection of these seminal iPhone prototypes provides insight into how they laid down foundations for today’s ubiquitous phone features.

Original iPhone Prototype

The creation of the iPhone was marked by an initial prototype enveloped in utmost confidentiality. Codenamed ‘M68,’ this early version of the original iPhone remained concealed from a vast majority of engineers, with its final design being unveiled to them only as the official launch approached. More than just hardware, this prototype served as the foundation for what would become a transformative force within mobile technology sectors. The engineers dedicated to this covert endeavor were instrumental in crafting a communication tool poised to alter global connectivity.

This foundational model set the stage for Apple’s future endeavors in product innovation. It presented cutting-edge features and an intuitive user interface that would leave lasting impacts on subsequent Apple devices. In embodying Steve Jobs’ aspiration for a device that merged utility with visual appeal, from its elegant form factor to its pioneering touch interface, this prototype materialized his vision into reality—ushering in an era where both functionality and beauty coalesced seamlessly within technology products offered by Apple.

Early iPhone 4 Prototypes

The public fascination with iPhone prototype devices soared to new heights when an iPhone 4 prototype was accidentally left on a bar stool. Brian Hogan, the individual who stumbled upon it, couldn’t help but notice its sharp screen and distinctive design elements that set it apart from earlier models of iPhones. Despite being cloaked in a case meant to conceal its identity, this particular device did not escape the spotlight of avid tech followers and journalists, sparking intense conjecture about what features it might offer.

Engineered to pass unnoticed amongst ordinary devices, these prototypes were often mistaken for standard gadgets at first glance. Nevertheless, the inadvertent disclosure of an iPhone 4 prototype captured massive public interest and played a role in shaping how future Apple products would be perceived. The fallout from such leaks spurred heightened security around Apple’s developmental hardware as they sought ways to prevent similar incidents involving their closely-guarded technologies.

iPhone 6 and Beyond

Progression in the iPhone series was markedly seen with the introduction of the iPhone 6 prototype. This model ushered in substantial design innovations, creating a trendsetting ripple throughout the smartphone market. The prototypes for this version boasted more expansive screen dimensions and a slimmer build, influencing not only Apple’s future aesthetic direction but also setting standards across other brands. These designs underwent rigorous trials to validate their operational performance and ensure they were structurally sound.

The impact of the iPhone 6 prototype went on to resonate far beyond those devices that directly followed it. It was instrumental in popularizing larger display screens among smartphones, reflecting an industry-wide adoption of this feature subsequently. Serving as a critical juncture for Apple, this prototype exemplified their commitment to continuous innovation and responsiveness to evolving tastes within consumer markets.

Behind the Scenes: How Apple Creates iPhone Prototypes

Crafting iPhone prototypes is an intricate task that fuses artistic innovation with technical precision. The prototyping journey at Apple serves as the backbone of its inventive endeavors, promoting swift modifications and enhancements to concepts. This elaborate procedure progresses through numerous phases, beginning with an abstract idea and culminating in the final design, while adhering rigorously to Apple’s esteemed criteria for quality and functionality.

To safeguard their pioneering conceptions against rival companies and maintain a sense of anticipation, Apple adopts an extremely confidential methodology when developing these devices. Such stringent confidentiality extends to concealing prototype designs from many of their own engineers.

The quest for a prototype device at Apple transcends mere creation. It encapsulates the transmutation of novel ideas into consumer-ready products by persistently honing designs via successive iterations.

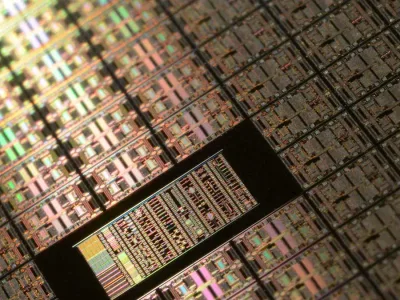

Silicone Molds and CNC Technology

During the initial phase of iPhone prototype development, Apple employs silicone molds to form the foundational designs. These molds facilitate a highly accurate portrayal of the envisaged product prior to commencing mass production. The advantage of using silicone molds lies in their ability to accommodate swift modifications and fine-tuning, guaranteeing that design specifications are meticulously honed before escalating to costlier production techniques.

Computer numerical control (CNC) technology is instrumental in crafting prototypes with precision machining of various components. By leveraging CNC machinery, each element within the prototype can be sculpted with exceptional accuracy – an imperative step for upholding both quality and functionality in the eventual consumer offering.

This strategic blend of utilizing silicone molding alongside CNC machining proves indispensable during the preliminary steps of assembling iPhone prototypes. This approach allows for precise construction leading up to intricately detailed and exact replicas ready for Development stages.

Mockups and Testing

The initial stages of the prototyping phase are marked by the creation of mockups, which act as tangible representations to showcase a design’s visual and functional intent. These early models typically lack operational capabilities, allowing for an evaluation focused on how the product feels and looks – vital aspects such as ergonomics and aesthetics are gauged before any actual hardware pieces come into play. This step affords designers with a concrete means to envision their concepts and enact adjustments prior to progressing towards more complex developmental phases.

With refinements in place, prototypes endure extensive testing to align with Apple’s stringent quality and performance benchmarks. The resilience, practicality, and overall feasibility of these evolved designs undergo examination during this critical stage. It is designed meticulously so that potential defects or flaws can be discovered promptly within the iterative cycle—thus precluding subsequent issues in completed merchandise.

Notable iPhone Prototype Leaks

Leaks of iPhone prototypes have consistently attracted considerable attention, affording an unusual look at Apple’s yet-to-be-released items. Such revelations typically escalate conjecture and excitement, affecting the way Apple orchestrates their media presence and product unveilings. The exposure of these rare iPhone prototypes serves as both a revelation into forthcoming tech features and a complication for maintaining Apple’s veil of secrecy around its marketing initiatives.

Historically, numerous significant leaks involving iPhone prototypes have captured the public interest and left an imprint on the technology sector. These disclosures go beyond merely unveiling upcoming functionalities. They mold consumer anticipations and steer trends within the realm of product innovation across the industry.

Gizmodo's iPhone 4 Leak

Brian Hogan became notorious for stumbling upon an iPhone 4 prototype at a California bar, which he then sold to Gizmodo. The incident not only exposed the upcoming device’s design, but also ignited legal issues as Apple fought to reclaim their property from Gizmodo. This event gave the public and media an unexpected glimpse into a yet-to-be-released iPhone, stirring up significant attention and challenging Apple’s typically stringent secrecy measures.

The ramifications of Hogan’s decision were considerable. It simultaneously stoked substantial interest from both the media and potential consumers in the forthcoming iPhone 4. Gizmodo’s thorough dissection of this leaked prototype shed light on how deep Apple delves into innovation and consumer astonishment within its design and development cycles.

The San Francisco Bar Incident

In April of 2010, Brian Hogan stumbled upon yet another iPhone 4 prototype in a bar setting off an intense media frenzy and fueling speculation. Hogan observed that this particular prototype boasted a screen resolution superior to existing iPhones, adding to the mounting excitement about the device. The situation shed light on the significant security hurdles Apple had to navigate and highlighted just how eager the public is for sneak peeks at forthcoming tech products.

As a result of his involvement with finding and handling the prototype, Hogan faced legal repercussions including mandatory community service and monetary penalties. Even though it was shrouded in controversy, this episode provided invaluable revelations regarding what to expect from iPhone 4’s design and features before its official launch, influencing how people perceived the phone ahead of time as well as elevating their anticipation for when it would be available publicly.

Unique Features of Rare iPhone Prototypes

Prototypes of iPhones frequently display distinctive features and designs that ultimately don’t reach the consumer market. Serving as experimental platforms, these uncommon prototypes highlight Apple’s dedication to exploring the limits of mobile technology with pioneering touch interfaces and fresh design concepts, offering a peek into potential future advancements in smartphone technology.

Investigating these exclusive features sheds light on Apple’s methodology towards innovation and design. Delving into these seldom-seen prototypes allows us to comprehend the process by which Apple tests out innovative ideas and technologies to determine what makes it through to their final products.

Unreleased Hardware Components

The fascination with iPhone prototypes largely stems from their inclusion of hardware components that never reach the public domain. These elements represent possible technological advancements that, despite their promise, are not always integrated into the commercial release. For example, cutting-edge materials such as titanium and aluminum have been explored in recent prototype versions to increase robustness while maintaining a slim profile.

This evolution towards materials that combine lightness with strength underscores Apple’s continuous pursuit to elevate both the functionality and durability of its devices. By trialing these substances within prototype models, Apple can evaluate whether they’re practical for mass production and how they might enhance overall user satisfaction before deciding on their use in subsequent iPhone iterations.

Experimental Software Features

iPhone prototypes are not only utilized to test cutting-edge hardware but also serve as a testing ground for experimental ios software features aimed at enriching the user experience. These prototypes often explore sophisticated systems for managing apps and dynamic user interfaces that adjust in response to how individuals use their devices. For instance, certain prototypes might include functions similar to Exposé, which enhance app switching and multitasking capabilities.

Apple’s pursuit of novel software features highlights its dedication to advancing how users engage with their devices and access functionality. By evaluating these features through prototype testing, Apple is able to collect invaluable feedback, enabling them to refine the software before releasing it in its completed form.

The Role of Prototyping in Apple's Innovation

The creation of prototypes is a key component in Apple’s approach to innovation, significantly influencing the design and capabilities of their offerings. The meticulous crafting and evaluation of iPhone prototypes are imperative for ensuring that each device adheres to the elevated benchmarks for excellence and efficiency set by Apple. This repetitive cycle of designing, testing, and improving is critical in turning pioneering concepts into products fit for consumers.

From its inception with the original iPhone through to current iterations, prototype development has been pivotal in propelling Apple’s technological advancements. Through relentless experimentation and improvement, Apple maintains its leading position within the industry while consistently presenting devices that surpass what customers anticipate.

From Concept to Final Design

The path from initial concept to finalized design is an intricate journey, marked by numerous phases of creating prototypes. The process starts with basic mockups that provide a tangible form for designers to assess functionality and execute preliminary tests, which then lead into more complex developmental stages. By engaging in this repetitive cycle of testing and refinement, the result is a thoroughly vetted design synonymous with quality.

For instance, prototype models such as the ‘Vesica Piscis’ amalgamate components sourced from various iterations including iPhone 13 Pro and iPhone 14 Pro to examine new innovations like haptic feedback buttons. Such experimental units afford Apple the opportunity to pursue groundbreaking concepts while gauging their practicality before making decisions about incorporating them into the ultimate design.

Ensuring Quality and Performance

Apple adheres to stringent testing protocols for iPhone prototypes, rigorously evaluating their quality and performance. Each prototype is put through a series of drop tests and exposed to various environmental conditions to determine its durability and functionality, ensuring that it meets Apple’s elevated standards.

Through this detailed testing procedure, any prospective issues are identified and rectified promptly, which guarantees the finished product offers an optimal user experience. These strict quality control practices enable Apple to consistently deliver devices that are both reliable and excel in performance.

Current Trends in iPhone Prototyping

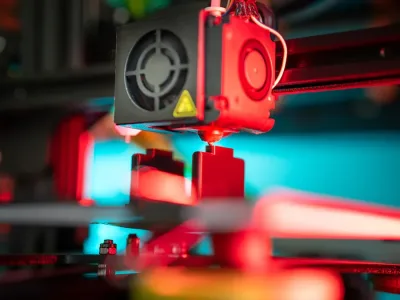

The latest approaches in crafting iPhone prototypes focus on swift modifications and incorporating consumer reactions to improve design elements. Notably, the introduction of the iPhone 6 marked a significant shift with its expanded screen size and upgraded camera functions, establishing new benchmarks for smartphone aesthetics. This progression towards larger displays and augmented capabilities persists as a key factor shaping upcoming models, showcasing Apple’s dedication to adapting to changing user desires.

Technological advancements in virtual tools and simulation applications have accelerated the prototyping phase significantly, enabling Apple to rapidly evaluate and refine their concepts. By adopting these cutting-edge technologies, Apple enhances its product development workflow, facilitating faster delivery of groundbreaking devices into consumers’ hands.

Use of Advanced Materials

There’s a noticeable move towards incorporating cutting-edge materials in the crafting of iPhone prototypes, with an emphasis on augmenting both durability and functionality. The integration of robust yet featherweight substances like titanium and aluminum into prototype designs is growing more common, showcasing Apple’s commitment to enhancing user experiences while extending device lifespan.

Speculation abounds that upcoming models, potentially including the iPhone 17, could boast aluminum-based frames – pointing to continuous advancements in material science at Apple’s R&D labs. These experiments with sophisticated materials enable Apple to evaluate their practicality for use and understand their possible effects on future consumer products.

Integration of AI and Machine Learning

The incorporation of artificial intelligence and machine learning is transforming the process of creating prototypes for iPhones. These AI tools expedite various phases of development, fostering rapid testing and refinement of novel designs. This results in more streamlined operations and enhances the quality of the end product, ensuring Apple maintains its lead in the fiercely competitive technology industry.

Machine learning algorithms are employed to anticipate user behaviors and inclinations, aiding designers in crafting interfaces that are both intuitive and aligned with user needs. By integrating AI into their prototyping methodology, Apple assures that its products consistently fulfill and surpass customer expectations.

Summary

Delving into the realm of iPhone prototypes, we uncover Apple’s intricate and pioneering approach to maintaining its leadership position in the tech sector. From the inception of the original iPhone to their most recent devices, each prototype epitomizes a progressive stride in both aesthetics and utility—propelled by Apple’s relentless pursuit for perfection and novelty. The employment of cutting-edge materials, stringent testing measures, as well as incorporating artificial intelligence and machine learning technologies, are all integral elements contributing to devising state-of-the-art devices that break new ground.

A closer examination of the development trajectory, distinctive features, and hidden efforts behind crafting iPhone prototypes fosters a more profound respect for technology that has revolutionized our digital experiences. It is through Apple’s unwavering commitment to prototyping that they can assure superior product quality and functionality while spurring perpetual innovation—a hallmark characteristic defining this iconic company. Peering ahead into what lies beyond today’s horizons serves as a reminder: it is undoubtedly these very iPhone prototypes which will persist at the heart of evolving mobile technologies yet to come.

Frequently Asked Questions

What role do silicone molds and CNC technology play in iPhone prototyping?

Silicone molds and CNC technology are crucial in iPhone prototyping as they enable the creation of precise design representations, allowing for rapid adjustments and ensuring high accuracy in components before full production.

How did the Gizmodo iPhone 4 leak impact Apple's prototype security?

The Gizmodo iPhone 4 leak resulted in stricter security measures at Apple, as the incident exposed vulnerabilities in their prototype protection and prompted significant changes to their secrecy protocols.

This event underscored the importance of safeguarding unreleased products.

What are some unique features found in rare iPhone prototypes?

Unique iPhone prototypes display advancements not found in the final products, such as titanium construction, innovative touchscreen interfaces, and experimental software capabilities.

These prototype features demonstrate Apple’s commitment to pushing the boundaries of technology through their exploration of state-of-the-art developments.

How does AI and machine learning integration benefit the iPhone prototyping process?

Integrating AI and machine learning into the iPhone prototyping process significantly enhances efficiency by enabling faster testing and iteration of designs.

Additionally, these technologies improve user experience through better anticipation of user interactions and preferences.

Why is prototyping essential to Apple's innovation strategy?

Prototyping is crucial to Apple’s innovation strategy as it enables rapid iteration and refinement, ensuring products meet high standards of quality and performance.

This continuous improvement is key to maintaining Apple’s competitive edge in the technology sector.

Disclaimer

The content appearing on this webpage is for informational purposes only. LKprototype makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LKprototype’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype