Share a little biographical information to fill out your profile. This may be shown publicly.

Understanding Prototypes and Their Importance A prototype is a model or early version of your invention that helps you test and refine your idea. Creating basic prototypes using everyday materials is an essential step in refining designs before moving into mass production. Prototypes are essential for identifying and fixing design flaws, understanding user needs, and gathering feedback. The prototype development process can save time and money in the long run by ironing out production issues and rectifying problems before mass production. Creating a proof of concept can further validate the feasibility of your invention before moving to more advanced prototyping…

CNC machining prototypes utilize advanced computer-controlled machines to create precise prototypes rapidly, showcasing their versatility and precision across various industries, including military, medical, automotive, aerospace, oil, and energy. This process is crucial in product development, offering advantages like speed, accuracy, and material versatility. Read on to explore the benefits and applications of CNC prototyping in various industries. Key Takeaways CNC prototype machining accelerates product development by enabling rapid iterations and precise prototypes that closely match final product specifications. The versatility of CNC machining allows for the use of various materials like metals, plastics, and composites, making it adaptable to diverse…

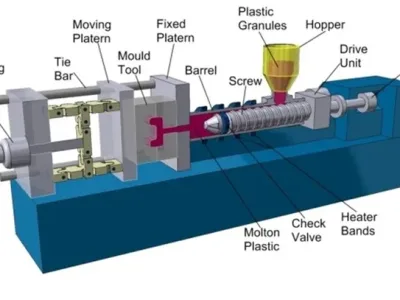

Plastic moulding techniques create the diverse plastic products we use daily. This article covers the main methods: injection, blow, compression, extrusion, rotational, and thermoforming. Learn about each method’s benefits and ideal applications to choose the best fit for your project, utilizing the plastic moulding technique that suits your needs. Key Takeaways Plastic molding encompasses several techniques, including injection, blow, compression, extrusion, rotational molding, and thermoforming, each suited for specific applications and materials. Injection molding is the most versatile method, allowing for high precision, consistent quality, and cost-effectiveness in mass production, while blow molding is ideal for creating hollow and thin-walled…

What is Urethane Casting Process: Benefits, Materials, Applications Cast urethane, also known as polyurethane casting, has emerged as a versatile and cost-effective method for producing high-quality prototype parts and low-volume production components. Unlike traditional manufacturing techniques such as injection molding or CNC machining, urethane casting provides unparalleled flexibility in material selection and design replication. This guide dives deep into the core aspects of urethane casting, offering fresh insights into its processes, applications, and innovations that go beyond common industry narratives. Urethane casting What Is Urethane Casting? Urethane casting is a manufacturing process that uses silicone molds to produce parts made…

Need to create a reliable mold for silicone casting? This guide covers everything from selecting materials to step-by-step techniques. Learn how to choose the right silicone rubber, mix and pour, and solve common problems for high-quality molds. Key Takeaways High-quality, food-grade silicone rubber and proper mixing tools are essential for successful silicone mold making. Choosing the right silicone rubber type, such as HCR or LSR, is critical for achieving specific mold requirements. Implementing advanced techniques like vacuum degassing and using release agents significantly enhances the quality and longevity of silicone molds. Essential Materials for Silicone Mold Making Urethane Silicone Casting…

Looking for plastic molders? These specialists transform raw plastics into precise components used in industries like automotive, electronics, and healthcare. This guide will help you understand the types of plastic molding, key materials, and what to look for when choosing a plastic molder. Key Takeaways Plastic molding is a versatile manufacturing process essential for producing a wide array of products across multiple industries, utilizing various specific techniques. Injection molding is a key process characterized by its cost-effectiveness, ability to produce intricate designs with high precision, and efficient mass production capabilities. Sustainability and technological advancements in plastic molding, such as bioplastics…

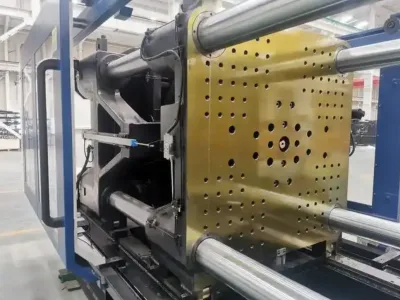

Often used manufacturing process to make high quality, precision engineered components is injection molding. A main progression point of injection molding involves the injection molding tools. These are vital components because these molds shape raw material to construct products in the best and shortest way. What is Injection Molding? A process used to manufacture parts is Injection molding where molten material is injected in a mold. This is a universal process employed across the automotive, electronics, medical device and consumer goods industries to create complex and precise components. The reason injection molding is the perfect manufacturing method is that it…

Urethane casting is an effective and economical way for the production of prototypes and small scale production. This is particularly used in the design, development of prototypes and manufacturing of small-volume products due to the flexibility that it provides. In this guide, you will explore the urethane casting process, materials, benefits, applications and its comparison to other casting methods. Urethane casting involves injecting polyurethane and additive resins into soft silicone elastomer molds, highlighting its cost-effectiveness and suitability for short production runs. What is Urethane Casting? Urethane casting is a kind of process where liquid urethane is filled into the mold…

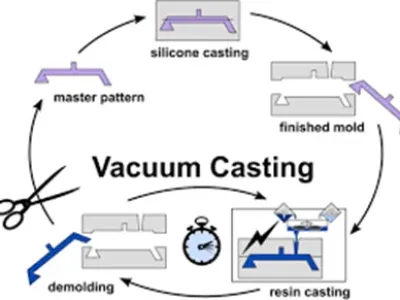

Vacuum Casting Services are extensively applied to short-time producing processes and designing trial production. Polyurethane vacuum casting is a specific technique used in these services, known for producing high-quality prototypes and small to medium production runs. This process results in parts with good detail and surface finish and with considerably less tool wear. It is effective in prototyping new designs, making fully functional prototypes and for developing relatively small numbers of components. What is Vacuum Casting? Vacuum casting is one in which the silicone rubber molds are made under a vacuum. These molds are then used to pour parts of…

The manufacturing process does affect the cost factors, time, quality, and size. Both cast urethane and injection molding are common techniques utilized in the making of parts for the automotive, aerospace, and consumer goods industries. They get to know the best method to use depending on their manufacturing, designing, and engineering requirements. What is Cast Urethane? Cast Urethane is a casting process in which a liquid polymer is delivered in molds to form parts. It is often used for low production volume and initial part making because of the manufacturing cost, type of material, and time consumption being lower than…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.