Share a little biographical information to fill out your profile. This may be shown publicly.

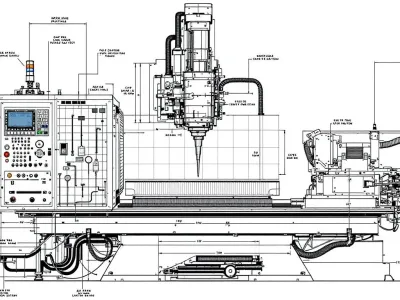

CNC machine tools, short for Computer Numerical Control tools, are automated machinery used in manufacturing for precise cutting, drilling, and shaping of materials. They replace manual tasks with software-guided operations, making production faster and more accurate. In this article, we’ll explore what CNC machine tools are, how they work, and why they are crucial in modern industry. Key Takeaways CNC machine tools utilize software for precise and automated machining, significantly improving efficiency and accuracy in manufacturing. There are several types of CNC machines, each designed for specific tasks, enhancing the versatility of machining processes across various materials. The advantages of…

Looking to speed up product development? Rapid prototyping services offer fast, precise prototypes for metals and plastics. This article explores key techniques and their benefits. Key Takeaways Rapid prototyping accelerates product development by allowing quick iterations and physical model creation from CAD data, utilizing techniques such as CNC machining, 3D printing, and vacuum casting. Key benefits of rapid prototyping include reduced development costs, faster feedback on designs, and early identification of design flaws, thus enhancing the overall efficiency of the product development lifecycle. Choosing the right rapid prototyping method depends on factors like budget, complexity, and production volume, with options…

Rapid prototyping softwares are crucial for turning design ideas into functional prototypes quickly. This article highlights the top 10 rapid prototyping tools for 2026, focusing on diverse needs like UI/UX design, collaboration, and ease of use. Discover the best options for speeding up your design process. Key Takeaways The top 10 rapid prototyping tools in 2026 include Figma, Marvel, and Proto.io, each offering unique features for various design needs. Selecting a rapid prototyping tool involves considering user interface intuitiveness, integration capabilities, and the specific project requirements. Rapid prototyping is crucial in product development for quick iterations, user feedback, and early…

Small batch CNC machining lets manufacturers produce precise parts in low volumes efficiently. It offers quick design adjustments and minimizes waste. This article covers its workings, benefits, and importance in specialized industries. Key Takeaways Small batch CNC machining enhances flexibility and customization, allowing manufacturers to quickly adapt to design changes and meet specific customer needs, making it essential for specialized industries. The transition to small batch production supported by advanced CNC techniques fosters precision and rapid prototyping, significantly reducing lead times and cost, thereby improving overall efficiency in manufacturing. Despite its advantages, small batch CNC machining faces challenges such as…

Searching for the best silicone mold makers? In this article, we will guide you through the top companies and what sets their molds apart. Learn about their quality, range, and how they can help with your DIY projects. Key Takeaways LKprototype is a top silicone mold provider, known for their expertise and quality, delivering molds with a 99.96% quality rate. A new Spring 2023 collection of silicone molds offers whimsical designs, perfect for DIY projects such as garden decor and seasonal decorations. Custom silicone molds are versatile for various applications, enabling personalized creations in baking, crafting, and resin art, with…

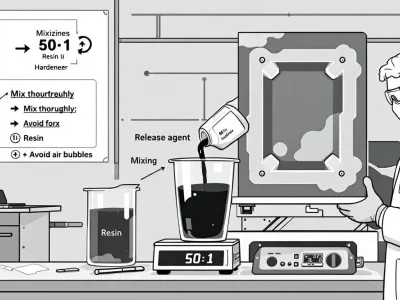

Need to know how to cast silicone rubber? This guide explains every step, from gathering materials to curing the final mold. Avoid common mistakes and achieve a successful cast. Key Takeaways Gather all necessary materials, including safety gear and high-quality silicone, to ensure a smooth casting process. Properly prepare the master model and construct a sturdy, leak-proof mold box to achieve flawless silicone casts. Follow careful mixing, pouring, and de-molding techniques to minimize air bubbles and ensure a successful final product. Gather Your Materials and Equipment Before embarking on the process of silicone casting, ensure that you have all the…

Plastic moulding is the process of shaping plastics into precise forms using molds, a fundamental manufacturing technique. This article covers key plastic moulding methods like injection, extrusion, and blow molding. We will examine their benefits, and applications across various industries. Key Takeaways Plastic molding is a versatile manufacturing process for shaping materials like polymers into complex designs. This is achieved using various methods such as injection, extrusion, and blow molding. Injection molding is the most efficient and cost-effective method for high-volume production. Other methods like compression and rotational molding are better suited for prototypes and large hollow parts, respectively. Selecting…

Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting them into molds to create parts and products, making it a versatile method for manufacturing plastic parts. But what is plastic injection molding? It is widely used because it allows for high-volume production with consistent quality and minimal waste. This method is essential in various industries, including automotive, medical, and consumer goods. In this article, we will explore the steps involved in the process, the benefits of using plastic injection molding, and its common applications. Key Takeaways Plastic injection molding is a versatile manufacturing process that…

Plastic molders are essential for creating precise, high-quality plastic parts. In this article, you’ll learn about the advanced methods plastic molders use and the benefits of partnering with a top-tier plastic molder like LKprototype Plastic Molders. Discover how they can help turn your concepts into reliable, market-ready products. Key Takeaways LKprototype Plastic Molders specializes in high-quality plastic manufacturing with over 15 years of experience, offering personalized customer service for both small and large orders. The company utilizes advanced plastic injection molding techniques, including Water-Assisted and Microcellular Injection Molding, to enhance product quality and reduce production times. Their comprehensive design and…

Curious about how to make hard plastic molds? Start with gathering your materials, then prepare your workspace, create a master model, apply a mold release agent, and pour the silicone. This guide takes you through every step for making durable, hard plastic molds. Key Takeaways Start by gathering key materials like silicone rubber, epoxy resin, and mold release agents for effective mold making. Creating a master model is essential, so use sculpting tools and materials like clay to achieve a precise design. After mixing and pouring, allow your silicone to cure properly before carefully removing the mold and adding finishing…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.