Vacuum casting is a highly cost-effective prototyping process—but how precise can it really be? In this guide, we dive into the typical tolerances achievable with urethane/a cast parts, the key factors that influence dimensional accuracy, and the quality control strategies you should use to minimize variation. Whether you’re designing for tight-fitting assemblies or functional prototypes, this page gives you a clear engineering-level understanding of what to expect, and how to design for optimal accuracy in vacuum cast components.

You can expect vacuum casting tolerance to be about ±0.3 mm or ±0.3% for most parts. This accuracy depends on a few important things:

Material choice and shrinkage rate matter the most. For example, polypropylene can shrink 0.010–0.020 in/in. The amount of shrinkage changes with the part’s shape.

Mold quality changes the final result.

Part geometry can make some features harder to keep within tolerance.

Vacuum casting takes out air bubbles. This helps you get smooth surfaces and detailed features.

Key Takeaways

Vacuum casting tolerances are usually about ±0.3 mm. Change your design to allow for material shrinkage.

Use good molds and patterns. Any problem in the mold will show up in every part made.

Watch the curing environment. Keep temperature and humidity the same for steady results.

Pick the right materials. Urethane resins shrink less than silicones, so this changes the final part size.

Follow good design rules. Keep wall thickness even and add draft angles to help remove parts from the mold.

Vacuum Casting Accuracy

Typical Tolerance Values

Vacuum casting can give you steady results if you know the usual tolerance numbers. Most parts made this way have a base tolerance of about ±0.010 inch, which is almost ±0.25 mm. If you have very small features, the tolerance can be as close as ±0.05 mm. Some guides talk about a growth factor. This means the tolerance goes up by ±0.003 inch for every inch of part length. Sometimes, you will see a percentage-of-length rule. It is usually between ±0.3% and ±0.5%. These numbers help you guess how close your part will be to your plan.

Here is a table with the most common tolerance values for vacuum casting:

Tolerance Type | Value |

|---|---|

Base Tolerance | ±0.010 inch (≈ ±0.25 mm) |

Growth Factor | ±0.003 inch per inch |

Alternative Baseline | ±0.015 inch |

Percentage-of-Length Specification | ±0.3% to ±0.5% |

Best-case Small-feature Outcome | ±0.05 mm |

You also need to think about shrinkage when you design your part’s size. Polyurethane resins, which are used a lot in vacuum casting, shrink about 0.15%. Tin-cure silicones can shrink even more, sometimes up to 4%. This means you should change your design so your finished part fits your needs.

Influencing Factors

Many things can change how exact your vacuum casting parts are. If you want the best results, you should focus on every step.

Mold and Pattern Quality: The master pattern and mold must be high quality. Any tiny mistake in the pattern will show up in every part. Molds can wear out or bend over time, which changes the tolerance and accuracy.

Vacuum Leaks: If the vacuum chamber does not get rid of all the air, you may get air pockets in your parts. These pockets can make your parts weaker and less exact.

Material Properties: Different materials act in different ways. Polyurethane resins flow well and shrink less. Tin-cure silicones can shrink much more. The thickness of the resin and how it hardens will change the final size.

Curing Process and Environmental Conditions: The temperature and humidity in your workspace can change how the resin hardens. If the room is too hot or cold, or if the humidity changes, your parts may not turn out the same every time. You should keep your materials in a room with steady temperature to get steady results.

Process Controls: You need to watch the timing and environment during curing. If you do not control these things, your parts may be more different from each other.

Here is a table that lists the main things that affect vacuum casting tolerance:

Factor | Description |

|---|---|

Mold/Pattern Quality | Mistakes get copied, and molds get worse over time, changing tolerances. |

Mold Degradation | Molds can break down or bend after many uses, changing accuracy. |

Vacuum Leaks | Not enough air removed causes air pockets, making parts less strong. |

Thermal Effects | Shrinking or bending changes with materials and temperature control. |

Material Properties | Resin thickness changes during pouring and hardening, causing differences. |

Curing Processes | You need good timing and watch the environment for steady results. |

Tip: Always look at your molds for damage before you use them. Keep your resins and molds in a steady place to keep your vacuum casting tolerance tight.

You should also watch out for common mistakes, like mold design errors, vacuum leaks, and bad resin handling. Thin areas or poor venting in the mold can make it hard for resin to flow, which can cause parts that do not meet your tolerance goals. Cold or thick resin can also cause trouble, as can air bubbles that form when the resin is not degassed well.

If you know about these things and plan for them, you can get good dimensional accuracy and meet standard tolerances for your vacuum casting projects.

Factors Affecting Vacuum Casting Tolerance

Material Choice

Picking the right material is very important for vacuum casting. Different materials, like urethane and silicone, change how close your part is to the size you want. Urethane casting usually gives a tolerance of about ±0.010 inch. You also add ±0.003 inch for every inch in length. Silicone molds are good for making fine textures and smooth surfaces. The table below shows how each material affects tolerance and other things:

Material Type | Tolerance | Key Properties Impacted |

|---|---|---|

±0.010 inch + ±0.003 inch/inch | Dimensional accuracy, surface replication | |

Silicone Molds | High precision in texture replication | Surface finish, dimensional precision |

When you pick a material, think about if it will shrink or get bigger during vacuum casting. This helps you keep your part close to the right size.

Mold Quality

The mold is a very important part of vacuum casting. If your mold is smooth and shaped right, your parts will be more accurate. Any bumps or mistakes in the mold will show up in every part you make.

Surface roughness can change because of things like how fine the grains are and how air moves through the mold. These things change how smooth the finished part is. Special coatings can help make the surface smoother. But they can also make the mold and part relationship more complicated.

Always check your mold before you use it. If you see damage or wear, get a new mold. This helps you make better parts with fewer problems.

Part Geometry

The shape of your part changes how well you can control vacuum casting tolerance. Simple shapes with even wall thickness cool evenly and keep their shape. Large, flat surfaces may warp during curing. Unsupported features can bend or sag, making it hard to hold tight tolerances. The table below explains how geometry affects tolerances:

Factor | Influence on Tolerances |

|---|---|

Wall Thickness | Uniform thickness leads to predictable cooling and reduced warping, enhancing accuracy. |

Large, Flat Surfaces | Prone to warping during curing, affecting flatness tolerance. |

Unsupported Features | Can deform under weight, leading to dimensional inaccuracies. |

Try to avoid thin walls or shapes that do not have support. This helps your part stay close to the size you want.

Process Controls

Good process controls help you get the best vacuum casting tolerance. You should:

Put the mold in a vacuum chamber before pouring to get rid of air.

Use special machines to remove bubbles from the casting material.

Watch and keep the vacuum level steady during the process.

These steps help stop air bubbles and keep your parts the right size. Always check your tools and keep your work area at a steady temperature. This helps your parts match your design.

If you know about these things, you can make better vacuum cast parts and get the tolerances you need.

Tolerances & Limits

Standard Tolerance Ranges

Vacuum casting usually gives you a steady tolerance range. Most parts made this way have a tolerance of about ±0.2 mm. If your part has tiny features, the tolerance can be as close as ±0.05 mm. Some guides say you should add ±0.015 inch for every inch of part length. This rule helps you guess how much your part might change from your plan.

Here is a table with common vacuum casting tolerance values:

Tolerance Type | Value |

|---|---|

Standard Tolerance | ±0.2 mm |

Fine Feature Tolerance | ±0.05 mm |

Per Inch Rule | ±0.015 in/inch |

Note: These numbers are a good place to start. Always check your material and mold to get the best results.

Shrinkage is another thing to think about. Vacuum casting usually shrinks about 0.15%. This happens because polyurethane and silicone molds change size with heat. If you see shrinkage higher than 0.15%, you should look at your mold design again.

Dimensional Limits

Vacuum casting lets you make small or big parts, but there are limits. The thinnest wall you can make is about 0.75 mm. Most designs work best with a wall thickness of 1.5 mm. For tiny parts, you can sometimes use walls as thin as 0.5 mm, but these can break more easily.

The biggest part you can make is about 1900 x 900 x 750 mm. The largest volume is around 10 liters. If you want to make bigger parts, use thicker walls to keep them strong.

Here is a table to help you plan your vacuum casting part:

Feature | Minimum Size | Maximum Size |

|---|---|---|

Wall Thickness | 0.75 mm | N/A |

Recommended Wall Thickness | 1.5 mm | N/A |

Maximum Part Dimensions | N/A | 1900 x 900 x 750 mm |

Maximum Volume | N/A | 10 liters |

The best minimum wall thickness is 1 mm (0.040 inches)

For tiny parts, you can go down to 0.5 mm (0.020 inches)

Bigger parts need thicker walls to stay strong

Shrinkage can change your final part size. The usual shrinkage rate for vacuum cast parts is about 0.15%. This happens because the material and mold change with heat. If you see more shrinkage, check your process and mold design.

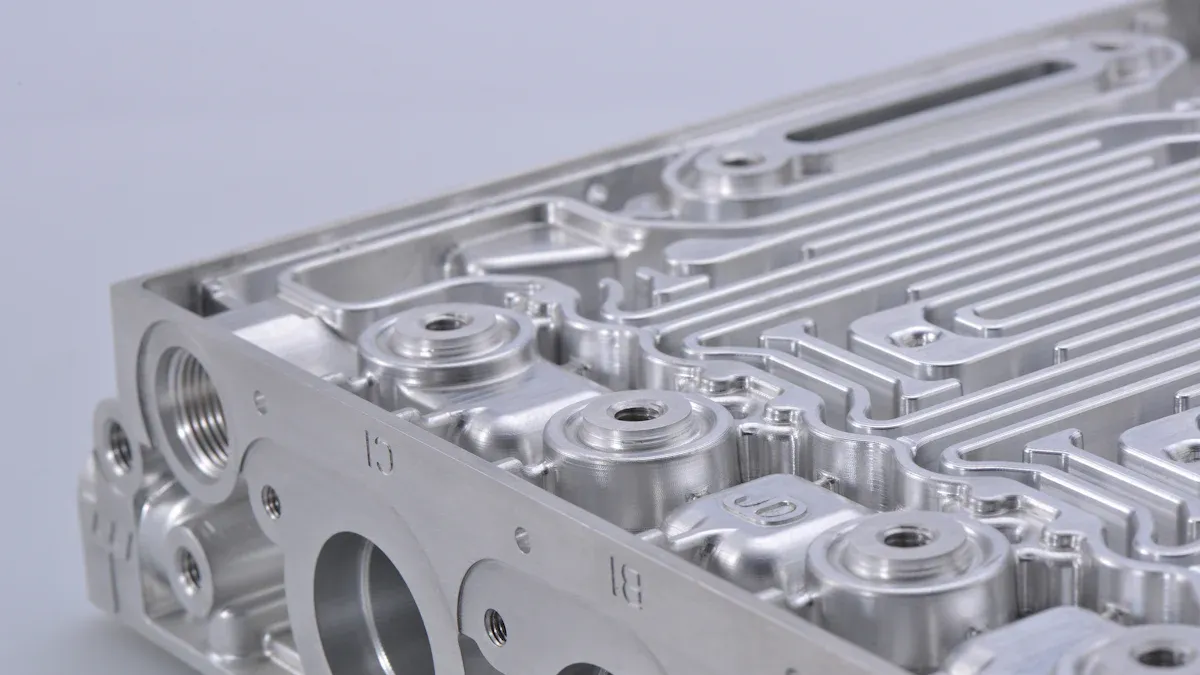

Comparison With Other Processes

If you compare vacuum casting to other ways to make parts, you will see some differences in tolerance and what you can do. Vacuum casting is good for prototypes and small batches, but it is not as exact as CNC machining or injection molding.

Here is a table that shows how vacuum casting tolerance compares to other methods:

Method | Tolerance |

|---|---|

Vacuum Casting | ±0.2 mm |

CNC Machining | ±0.05 mm |

Injection Molding | ±0.025 mm |

Vacuum casting can reach tolerances of ±0.2 mm.

CNC machining can get as close as ±0.05 mm.

Injection molding can get as close as ±0.025 mm.

Injection molding gives you the finest details and tightest tolerances. CNC machining also makes very exact parts. Vacuum casting is better for simple parts and when you want to make your design quickly and save money.

Manual steps in vacuum casting can make it hard to repeat the same results every time. You might see more small flaws or differences between parts. Shrinkage can make some features too thick or too thin if you do not plan well.

Tip: Use a vacuum casting design guide to pick the best way to make your part. If you need very exact parts or lots of copies, try CNC machining or injection molding. If you want speed, flexibility, and a nice surface for prototypes, vacuum casting is a good choice.

Vacuum casting gives you a mix of speed, cost, and quality. You can use it to test ideas, make working prototypes, or make small batches. If you know the limits and tolerances, you can make your vacuum casting design with confidence.

Quality Tips

Design Best Practices

You can get better vacuum casting parts by using smart design ideas. Start by looking at a vacuum casting design guide to help plan your part. Use a general tolerance of ±0.3 mm when you first set your part’s size. If your part needs to fit with other pieces, add small gaps for assembly. Add a draft angle of at least 0.5° so you can take the part out of the mold more easily. This also helps your mold last longer. Try to keep the wall thickness the same everywhere, and make sure it is at least 1 mm thick. If your part has big flat areas, add ribs to make them stronger. Ribs should not be thicker than 60% of the wall thickness. If you need to add bosses for screws or fasteners, keep them thinner than 60% of the part’s thickness.

Design Strategy | Recommendation |

|---|---|

Tolerance Management | ±0.3 mm for first sizes; add space for assembly |

Draft Angles | At least 0.5° for easy removal and longer mold life |

Uniform Wall Thickness | At least 1 mm; change if needed for bigger parts |

Reinforcement with Ribs | Add ribs; ribs should be 60% or less of wall thickness |

Incorporating Bosses | Add bosses; keep them under 60% of part thickness |

Tip: Keeping wall thickness even and using draft angles helps you make good prototypes and avoid problems.

Mold Preparation

Getting your mold ready the right way helps you make better vacuum cast parts. Clean the inside of the mold before you use it. Put a release agent on the mold so the part does not stick. Make sure the cover die and ejector die fit together tightly. This keeps air from leaking in and stops defects. Always check that all parts of the mold fit well and have no gaps.

Clean the mold before every use.

Use a release agent like mold oil or wax.

Put mold parts together tightly so there are no leaks.

Process Monitoring

Watch every step to keep your vacuum casting parts high quality. Mix the resin in the right amounts and remove bubbles by degassing. Keep the temperature the same while you pour and cure the resin. Check each part’s size with calipers or micrometers. Use a magnifying glass and good light to look for surface problems.

Method | Description |

|---|---|

Resin Preparation | Mix the right amounts and degas to stop bubbles |

Temperature Control | Keep the temperature steady during pouring and curing |

Dimensional Inspections | Use calipers or micrometers to check size |

Visual Examination | Look for surface problems or defects |

Using better monitoring tools helps you make custom vacuum cast parts with fewer mistakes.

Post-Processing

Post-processing makes your vacuum cast parts look and work better. Cut off extra material like flash or sprues. Polish the part to make it smooth. Paint or coat the part to make it last longer and look nice. Check each part for air pockets, warping, or spots that did not fill. Use accurate tools to make sure your part meets tight tolerances.

Technique | Description |

|---|---|

Trimming and Polishing | Cut off extra material and polish for smooth surfaces |

Painting or Coating | Add paint or coating for strength and looks |

Quality Checks | Look for problems and check the size |

Vacuum casting lets you make prototypes fast and gives results close to injection molding. You can get great parts if you follow these tips.

You can get good results with vacuum casting if you know the tolerance limits and watch each step. If you pay close attention to the material, mold, and process, you can reach your design goals. Vacuum casting helps stop tiny holes from forming. This makes your parts strong and accurate. The table below shows some main benefits:

Key Takeaway | Description |

|---|---|

Minimization of Porosity | Vacuum casting cuts down gas bubbles, so parts are stronger. |

Consistent Performance Metrics | You get exact sizes and smooth surfaces for engineering work. |

Compatibility with Post-Processing | Fewer mistakes make heat treatment and welding easier. |

Use these tips to make your vacuum cast parts the best they can be.

FAQ

What is the typical tolerance for vacuum casting?

You can expect a standard tolerance of ±0.2 mm for most vacuum cast parts. Small features may reach ±0.05 mm. Always check your material and mold for the best results.

How does material choice affect accuracy?

Material choice changes shrinkage and surface finish. Urethane resins shrink less and keep tight tolerances. Silicone molds help you get smooth surfaces. Pick the right material for your design needs.

Can you use vacuum casting for large parts?

You can make large parts up to 1900 x 900 x 750 mm. Thicker walls help keep big parts strong. Thin walls may break or warp, so plan your design carefully.

How do you avoid air bubbles in vacuum casting?

You should degas the resin before pouring. Use a vacuum chamber to remove trapped air. This helps you get smooth surfaces and strong parts.

Is vacuum casting better than 3D printing for prototypes?

Vacuum casting gives you smoother surfaces and better material choices. You can make small batches quickly. 3D printing works well for complex shapes but may show layer lines.

LKprototype

LKprototype