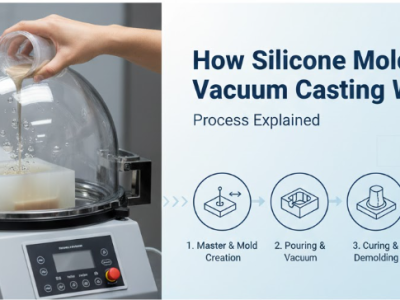

When you use the vacuum casting process explained here, you start with a high-quality master model. You get the surface ready so it is smooth. Then you make a silicone mold that copies every detail of your high-quality master model. You mix and remove air from the silicone. Next, you pour it over the high-quality master model and let it harden. After you check the mold, you fill it with resin using the vacuum casting process explained. This makes sure there are no air bubbles. The vacuum casting process explained makes copies of the high-quality master model. These copies have…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.