Imagine you order silicon molds for baking, thinking they are flexible trays, but you get hard, breakable blocks instead. This mistake can slow down your work and cost you money. Many people mix up silicon molds and silicone molds. You should know the difference if you make things or design products. Using the right word helps you avoid expensive mistakes and keeps your projects going well. Key Takeaways Silicon is a hard and breakable element. People use it in electronics. Silicone is soft and bends easily. People use it for baking and in medical items. Silicone molds are safe to…

Silicone molding production technology Silicone molds go through four main stages: design, production, use, and care. Each stage is important for keeping the mold working well and lasting longer. Knowing these steps helps improve performance and avoid delays. The silicone molding industry is becoming more important. The market was worth 3.45 billion USD in 2023. It may grow to 5.5 billion USD by 2032. Makers now use greener materials and better tools to meet custom needs. New technologies improve how molds are made and checked. Lightweight silicone rubbers are popular for saving fuel in some industries. These changes show why…

Silicone molds for resin are very useful in manufacturing today. They are flexible and help make accurate and detailed parts for many industries, like cars and healthcare. Silicone molds make production faster, which is great for custom designs and small batches. The Vacuum Casting Machine Market might reach 0.65 million USD in 2023. This shows how important silicone molds are. Industries like electronics and airplanes use these molds to make cheap prototypes. Silicone molds help make work easier while keeping quality and speed high. Key Takeaways Silicone molds are bendable and strong. They help make detailed parts for many industries,…

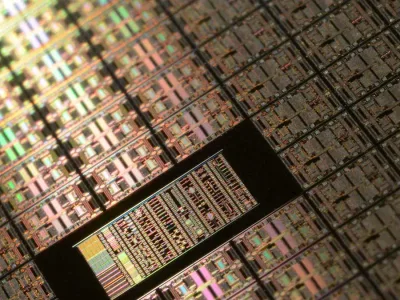

Custom silicone molds are important tools for work and hobbies. They are useful because they can change and are dependable. You can see them used in baking and making products. Their special features—like being bendable, strong, and safe—make them popular with workers and DIY fans. Here are some ways industries use these molds: Car makers use them for parts like gaskets and seals that handle tough conditions. Electronics companies use them to protect parts from dust and water. The healthcare industry likes silicone because it is safe for the body, so it’s great for medical tools. Builders use silicone for…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.