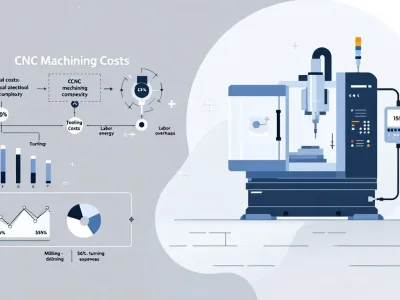

Are you looking to achieve low cost CNC machining without sacrificing quality? This guide offers valuable insights into reducing CNC machining expenses. You’ll learn about factors that impact costs, tips for cutting down expenses, and affordable CNC machine options for small businesses. Dive in to discover strategies that can optimize your CNC machining processes efficiently. Key Takeaways CNC machining costs are influenced by material selection, design complexity, machine setup time, and production volume. Key strategies to reduce CNC machining costs include optimizing material usage, simplifying designs, bulk ordering, and minimizing finishing operations. Low-cost CNC machining provides significant advantages like cost…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.