Need to quickly convert your CAD designs into physical models? Rapid prototyping services offer a fast and reliable way to create prototypes for testing and validation. This article dives into the different technologies available, the materials you can use, and how these services can accelerate your product development. Key Takeaways Rapid prototyping is essential for quickly producing functional prototypes from CAD models, enabling early design testing and iterations. Key technologies in rapid prototyping, such as CNC machining, 3D printing, and injection molding, provide flexibility and efficiency for both low and high-volume productions. Selecting appropriate materials is crucial for prototype characteristics,…

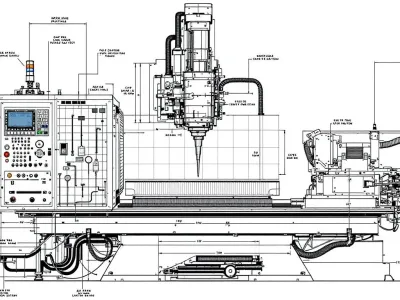

5 axis CNC routing allows for high precision and flexibility in cutting materials by adding two rotational axes to the traditional X, Y, and Z movements. This technique is vital for industries that require complex parts, such as aerospace and medical devices, as it can produce components that fit reliably and quickly according to the exact specifications provided by the customer. In this article, we’ll dive into its benefits, top machines, applications, and features to consider. Key Takeaways 5-axis CNC routers offer enhanced precision and versatility, enabling complex geometries and efficient multi-directional operations. Key benefits include reduced setup time, increased…

A 2 axis CNC machine operates on the X and Y axes to cut, drill, and engrave materials with precision. These machines are vital in industries like automotive and aerospace for crafting intricate parts. In this guide, we’ll dive into the types of 2 axis CNC machines, their features, and how they can benefit your projects. Key Takeaways 2 Axis CNC Machines offer precision manufacturing capabilities for various industries through X and Y axis movements, enabling intricate designs and complex parts. The three primary types of 2 Axis CNC Machines—vertical, horizontal, and gantry—each serve different purposes and have unique advantages,…

5 axis CNC routing transforms modern manufacturing by allowing the creation of complex geometries with high precision. Unlike the more common 3-axis CNC machines, 5-axis CNC routers offer two additional rotational movements, enabling the cutting tool to approach the workpiece from virtually any angle. This capability results in superior machining efficiency and precision, especially beneficial for industries like aerospace and automotive where intricate designs are essential. Key Takeaways 5-axis CNC routing provides enhanced precision and efficiency by allowing simultaneous machining of multiple surfaces, reducing production time and minimizing the need for workpiece repositioning. Key features such as continuous C-axis rotation,…

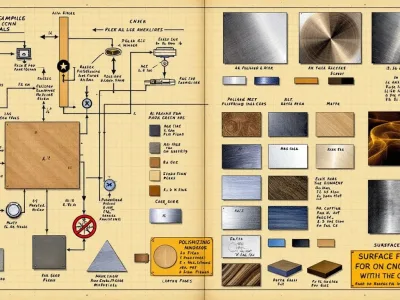

When it comes to CNC machining, selecting the right CNC machining materials is crucial. In this guide, we’ll explore the most common materials for CNC, like metals and plastics, and help you determine which one best fits your specific project needs. Key Takeaways Key metal materials for CNC machining include aluminum alloys, stainless steels, and carbon steels, each offering distinct properties suitable for diverse applications. Plastic materials such as ABS, Nylon, and PEEK provide advantages like lightweight properties and chemical resistance, making them ideal for prototypes and demanding applications. Factors influencing CNC material selection encompass application requirements, cost considerations, and…

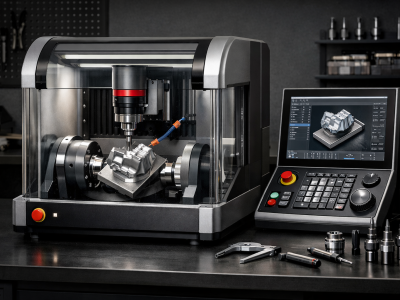

Looking to achieve high precision in a small workspace? A 5 axis desktop CNC machine provides advanced capabilities needed for complex designs. They are perfect for industries like aerospace, medical devices, and jewelry. In this article, we review the top 5-axis desktop CNC machines available today. Key Takeaways 5-axis desktop CNC machines offer advanced machining capabilities from multiple angles, maintaining high precision suitable for various industries such as aerospace and medical device manufacturing. Compact designs of these machines significantly save floor space while delivering high performance, making them ideal for workshops with limited space. With integrated software solutions and user-friendly…

Wondering about CNC machine prices? They range from a few thousand to hundreds of thousands of dollars. This guide will help you understand the factors that impact CNC machine prices, and find the best deal available. Understanding the CNC machine price is essential for making an informed purchase. Key Takeaways CNC machine prices vary widely, influenced by factors such as size, material compatibility, and advanced features, with costs ranging from $2,000 to over $500,000. Buyers should consider the total cost of ownership, including installation, maintenance, and tooling, alongside the initial purchase price for effective budgeting. Researching and comparing various models,…

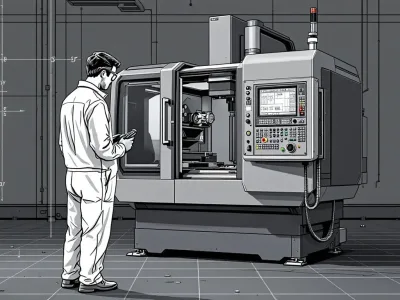

CNC machine tools, short for Computer Numerical Control tools, are automated machinery used in manufacturing for precise cutting, drilling, and shaping of materials. They replace manual tasks with software-guided operations, making production faster and more accurate. In this article, we’ll explore what CNC machine tools are, how they work, and why they are crucial in modern industry. Key Takeaways CNC machine tools utilize software for precise and automated machining, significantly improving efficiency and accuracy in manufacturing. There are several types of CNC machines, each designed for specific tasks, enhancing the versatility of machining processes across various materials. The advantages of…

Looking to speed up product development? Rapid prototyping services offer fast, precise prototypes for metals and plastics. This article explores key techniques and their benefits. Key Takeaways Rapid prototyping accelerates product development by allowing quick iterations and physical model creation from CAD data, utilizing techniques such as CNC machining, 3D printing, and vacuum casting. Key benefits of rapid prototyping include reduced development costs, faster feedback on designs, and early identification of design flaws, thus enhancing the overall efficiency of the product development lifecycle. Choosing the right rapid prototyping method depends on factors like budget, complexity, and production volume, with options…

Small batch CNC machining lets manufacturers produce precise parts in low volumes efficiently. It offers quick design adjustments and minimizes waste. This article covers its workings, benefits, and importance in specialized industries. Key Takeaways Small batch CNC machining enhances flexibility and customization, allowing manufacturers to quickly adapt to design changes and meet specific customer needs, making it essential for specialized industries. The transition to small batch production supported by advanced CNC techniques fosters precision and rapid prototyping, significantly reducing lead times and cost, thereby improving overall efficiency in manufacturing. Despite its advantages, small batch CNC machining faces challenges such as…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.