CNC metal machining uses computer-controlled tools to precisely cut and shape metal into custom parts with high accuracy and efficiency. This guide explores CNC machining processes, machine types, metals used, and key steps to produce high-quality parts. Key Takeaways CNC metal machining utilizes automated systems for precise manufacturing, enhancing efficiency and safety compared to traditional methods. Various types of CNC machines, including milling machines, lathes, and multi-axis machines, cater to different machining needs and capabilities. CNC machining’s cost and efficiency are influenced by factors such as part complexity, material choice, and production volume, making it a versatile option for various…

Automotive CNC machining plays a crucial role in manufacturing precise and reliable car parts. From engine components to suspension systems, this technology enhances vehicle performance and efficiency. Read on to discover its applications, benefits, and why it’s vital in the automotive world. Key Takeaways CNC machining is essential in automotive manufacturing for producing high-precision components, including engine parts, transmission elements, and suspension systems, enhancing overall vehicle performance and safety.Advanced technologies, such as AI and IoT, are transforming CNC machining by improving operational efficiency, precision, and integration in the automotive sector, enabling rapid prototyping and smart manufacturing practices.Sustainable practices in CNC…

CNC machining products are essential in automotive, aerospace, electronics, and healthcare industries. They are also crucial in the defense industry for producing weapons, ammunition, and military vehicles, as well as in the marine industry for creating durable, corrosion-resistant parts for vessels. These parts offer unparalleled precision and consistency. This article explores the key CNC machined components and their diverse applications. Key Takeaways CNC machining enhances efficiency, precision, and consistency in producing critical components across industries such as automotive, aerospace, electronics, healthcare, defense industry, and marine industry. The technology supports a wide range of materials, including metals and plastics, allowing manufacturers…

Medical device prototyping involves creating early models of medical devices to test, refine, and perfect designs before mass production. By quickly identifying and resolving design flaws, prototyping ensures that the final product is safe, effective, and meets regulatory standards. In this article, we will explore the key stages and advanced techniques of medical device prototyping, offering insights for anyone involved in the development of innovative medical technologies. Key Takeaways Medical device prototyping is essential for transforming concepts into functional products, allowing for early design validation and risk reduction.The prototyping process involves key stages such as conceptualization, material selection, and iterative…

Before electronic devices enter mass production, innovators develop prototypes as initial models to examine and improve their concepts. This crucial stage allows for the testing and perfecting of design details. It helps to confirm functionality, reduce potential risks, and certify that product standards are met. By having the devices prototyped, it becomes possible to determine cost-efficiency and identify potential defects early. Consequently, this helps prevent higher expenses during manufacturing. We will delve into the fundamental phases of electronic prototyping in this article and provide valuable advice for efficiently advancing your projects. Key Takeaways Electronic prototyping validates design and functionality, minimizing…

Prototyping manufacturing helps you develop products efficiently. You create early test versions to spot and fix issues, saving time and money before mass production. This article explores best practices and techniques in prototyping manufacturing. Key Takeaways Prototyping manufacturing is essential for identifying design flaws early, reducing risks, and accelerating product development. The selection of the right prototyping method and materials significantly impacts the functionality, cost, speed of the product development process. Emerging trends, including advanced materials and automation, are enhancing prototyping efficiency and enabling the development of complex, high-quality prototypes. What is Prototypeing Manufacturing? Manufacturing prototypes involves the creation of…

Automotive CNC machines are vital for modern vehicle manufacturing, providing the precision needed for components like engines and transmissions. Discover how automotive CNC machine technology enhances quality and efficiency across the automotive industry. Key Takeaways CNC machining enhances precision, speed, and efficiency in automotive manufacturing, crucial for producing complex components while meeting stringent safety standards. Key applications of CNC machining in the automotive industry include the production of engine components, transmission systems, and interior/exterior panels, all requiring high precision for optimal performance. Emerging trends in CNC machining, such as the integration of AI and the use of advanced materials, are…

Looking for ideas on what CNC machine products you can create and sell? The rise of affordable CNC machines has democratized the ability to produce custom items for small businesses and hobbyists. This article highlights the top 30 items, from custom signs and phone cases to jewelry and spare parts, showcasing the wide range of possibilities CNC technology offers. Key Takeaways CNC machining offers vast customization options for various products, such as custom signs, phone cases, and key holders, allowing businesses to cater to diverse customer preferences. High-quality materials and precise manufacturing enable CNC-created items like toys, jewelry, and lampshades…

Looking to bring your product idea to life? This guide on how to develop a product prototype breaks down the essential steps. From your initial concept to a refined, testable prototype, you’ll learn the process to create a tangible, user-ready product. Key Takeaways Prototyping helps visualize and test product ideas early, identifying potential flaws and saving time and money in development. User testing and feedback during the prototyping process are crucial for refining products to better meet user needs and expectations. Protect your intellectual property by using patents and non-disclosure agreements (NDAs) to secure your product ideas while collaborating with…

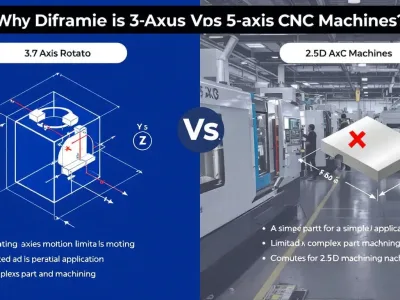

Choosing between a 3 Axis CNC and a 5 Axis CNC machine depends on your project’s complexity and precision needs. In this article, we will explore the key differences, benefits, and drawbacks of 3 axis CNC vs 5 axis machines to help you decide which is right for you. Key Takeaways 3-axis CNC machines are cost-effective and suitable for simpler tasks, but they struggle with complex geometries and require multiple setups for intricate designs. 5-axis CNC machines excel in precision and efficiency, capable of machining complex shapes with fewer setups, making them ideal for industries demanding high accuracy like aerospace…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.