Machining bronze adds great value to your projects. This strong metal lasts long, resists rust, and is easy to shape. Many industries prefer it for these reasons. But, machining bronze can be tricky. Tools can wear out, and heat can build up. Using the right tools and methods solves these problems. Bronze parts are used in boats and electrical systems. They work well because they are strong and dependable. With these special traits, bronze is perfect for making top-quality products. Key Takeaways Machining bronze is strong and doesn’t rust, so it lasts long. Picking the right bronze type makes machining…

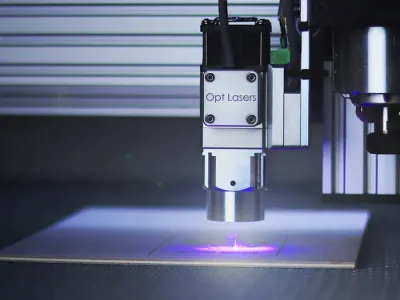

Choosing the right metal CNC machine is very important today. It helps make products the same every time with fewer mistakes. These machines use computers to follow exact instructions. They can work nonstop, making things faster and producing more items. They also save materials, which lowers costs and increases profits. Picking a machine that fits your needs gives better results. This choice improves work speed and helps you reach your goals easily. Key Takeaways Picking the right metal CNC machine makes work faster and better. It helps you reach your production goals easily. CNC machines, like milling, lathes, or laser…

Precision is very important in CNC machining bronze. Bronze is strong, resists rust, and handles heat well, making it great for producing parts like bushings and gears. However, its unique traits can make CNC machining tricky. To achieve good results, it's essential to use the right tools and methods. With practice, you can address issues like worn tools or rough surfaces, which helps create high-quality parts. Key Takeaways Pick the correct bronze type for your work. Each type has special traits that affect strength and use. Use strong carbide tools to cut bronze. They last longer and make smooth surfaces.…

CNC metal machining uses computers to shape metals very precisely. This technology has changed manufacturing by making it faster and better. For example, CNC machines work up to 15 times faster than hand tools. They also waste less material, saving money and keeping exact measurements. These features make CNC machining important for making detailed parts for planes, cars, and electronics. Using CNC machines helps you get the same results every time and makes production easier. Key Takeaways CNC machining works faster and is more accurate than old methods. It is important for industries like airplanes and cars. Picking the right…

Acrylic is a great material for acrylic CNC machining. It is affordable and can be used in many ways. It is easy to work with and looks clear and shiny, making it perfect for industries that require precise work. Acrylic is a good choice when you need a strong, see-through material at a low cost. Accuracy and speed are very important when performing acrylic CNC machining. Its density is 1.18 g/cm³, and its strength is 70 MPa. These features help you achieve excellent results without damaging the material. Acrylic also allows 92% of light to pass through, making it ideal…

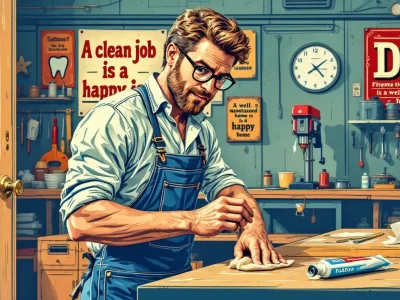

Looking to restore your brass to its original shine quickly and effectively? This guide will show you how to polish brass metal using common household items and simple techniques. Get ready to make your brass shine again. Key Takeaways Identify whether your brass item is solid or plated before cleaning to choose the right method.Effective cleaning methods include natural solutions like lemon juice and baking soda, toothpaste, and even ketchup, each with specific techniques for application and rinsing.Regular maintenance is key; high-use brass items should be cleaned monthly, while decorative pieces can be cleaned annually. Determine if Your Brass is…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.