A CNC Wood Cutting Machine uses speed and accuracy for woodworking jobs. You can change settings like spindle speed, cutting depth, and feed rate to get different results. For example: Spindle speeds from 8000 to 12,000 RPM work for many wood types. Cutting depths between 0.08 and 0.20 inches make deeper cuts while keeping good quality. Feed rates of 0.003 to 0.005 inches per tooth balance smooth surfaces and tool wear. These settings help the machine cut solid wood and hardwood up to 150mm thick well. Knowing these settings lets you improve the machine for your needs. Key Takeaways Change…

Training CNC machine skills is crucial for success in today's manufacturing landscape. Many industries require skilled workers to operate CNC machines and produce precise parts. The CNC machine market is projected to expand by 44%, reaching $35 billion by 2026. Despite this growth, companies face challenges in finding trained workers. For instance, Connecticut has between 8,000 to 10,000 open machining positions. Additionally, 40% of companies report difficulties in locating workers with the necessary skills. Engaging in training for CNC machines helps bridge this skills gap. It also equips you with the expertise needed to fulfill industry demands. By mastering CNC…

A CNC operator is a trained worker who uses and monitors computer-controlled machines. These machines create parts with high precision by following specific instructions. So, what is a CNC operator? As a CNC operator, you play a crucial role in ensuring that every part is manufactured correctly. Your job maintains high-quality and efficient production. For instance: Statistical process control (SPC) enhances the reliability of CNC machining. Process capability indices, such as Cp and Cpk, indicate how well parts conform to design specifications. A Cp of 1.33 suggests that only 1 out of 16,000 parts will fall outside the limits. Modern…

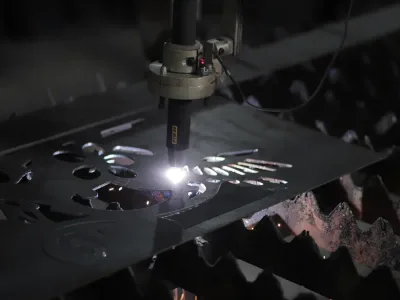

CNC innovation this year is being driven by faster motion control, higher spindle power, and smarter automation packages. Entry-level mills such as Tormach’s new-gen 1100MX have broken the US $30 000 barrier for real BT-30 machining, while high-power 12 kW fiber lasers—TruLaser 5030, ByStar 3015 and Amada ENSIS 3015—cut 1-in-plus mild-steel plate at speeds that eclipse mid-range CO₂ units. Multitasking centers like Mazak’s INTEGREX i-450H ST consolidate turning, five-axis milling and Y-axis drilling in one setup, and even the water-jet and plasma sectors have leapt forward with easier touchscreen controls and predictive maintenance. Together these trends mean more throughput per…

NC (Numerical Control) and CNC (Computer Numerical Control) machines have revolutionized manufacturing. NC machines rely on manual programming with punched cards or tape, while CNC machines utilize computers to automate tasks. This key difference fundamentally alters how production is carried out. Understanding these distinctions is crucial for making informed decisions in manufacturing. CNC machines operate continuously and require minimal supervision. They significantly reduce setup time and offer high precision. This leads to fewer errors, less material waste, and more efficient resource utilization. Choosing the right NC CNC machine can enhance productivity, cut costs, and elevate quality. Key Takeaways NC machines…

Computer Numerical Control (CNC) technology changes manufacturing by using machines. These machines work automatically and make parts with great accuracy. CNC systems help create complex parts quickly and with the same quality every time. The global CNC market is growing fast. It is expected to rise from $90.5 billion in 2024 to $144.4 billion by 2033. This means it will grow about 5.06% each year. By 2030, over 2.8 million CNC machines may be needed. New high-speed machining makes this possible. This technology helps factories work faster and grow easily. Key Takeaways CNC machines help make parts faster and more…

Imagine a CNC machine metal device that turns raw metal into precise parts. That’s what CNC machines do. They change manufacturing by using automation and programming to make perfect results every time. CNC machines have changed industries by working faster, wasting less, and repeating tasks perfectly. Here’s how they’ve made a difference: Valve factories using CNC machine metal technology cut setup time a lot between 1997 and 2002. Companies using CNCs needed more workers with engineering skills (from 52% to 72%) and programming skills (from 14% to 43%). CNC machines run fast all the time, saving time and keeping products…

CNC machines for metal have transformed how we work with this material. They can perform challenging tasks automatically, making them extremely valuable in industries such as car manufacturing, defense, and aerospace. Did you know the CNC market might reach $129 billion by 2026? This significant growth highlights the importance of CNC machines for metal in today's world. By 2025, advancements in technology like robots and 3D printing will enhance CNC machines for metal even further. These improvements will increase precision, conserve materials, and accelerate production. Whether you are producing small components or large structures, selecting the right CNC machine for…

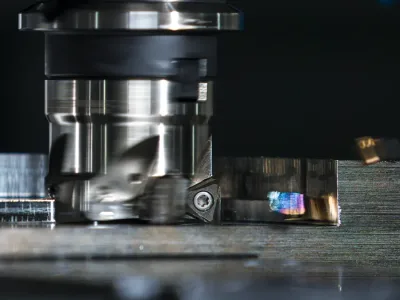

Image Source: pexels Climb vs conventional milling are two basic machining methods. In climb milling, the cutter spins in the same direction as the material moves, resulting in smoother finishes and reduced cutting forces. On the other hand, conventional milling operates differently; the cutter spins against the material's movement, which can generate more heat and increase tool wear. Understanding the differences between climb vs conventional milling is crucial for machinists. Climb milling produces smoother surfaces by pushing chips behind the cut, while conventional milling moves chips upward, potentially damaging the surface finish. Choosing the appropriate method not only extends tool…

CNC milling machines, controlled by computers, are essential tools in modern manufacturing. They precisely guide cutting tools to remove material with accuracy, playing a crucial role in producing detailed and precise components. The demand for CNC milling machines increases by 12% annually, driven by advancements in automation and improved technology. Integrating CNC milling machines with robotic systems accelerates production processes and addresses the challenge of a shortage of skilled workers. These machines enhance operational efficiency, making them indispensable for industries in the present day. Key Takeaways CNC milling machines are important in today's manufacturing. They make precise and complex parts…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.