When silicone cure inhibition happens during molding, you need to act fast. Cure inhibition stops silicone from setting. This wastes time and materials. You should find the problem early and fix it the right way. A clean workspace helps stop sticky or soft spots. Using the right cleaning method also helps. The table below shows how different ways can change your results:

Type of Silicone | Sensitivity to Contaminants | Impact on Production Costs and Timelines |

|---|---|---|

Platinum Cure | Sensitive to sulfur | Costs and time go up because you need a clean workspace and more testing |

Tin Cure | More forgiving | Costs and time go down, and it is easier for beginners in places that are not controlled |

You can do better by picking the right silicone. Clean your molds well. Use barrier coatings if you need them.

Key Takeaways

Cure inhibition keeps silicone soft. This wastes time and materials. It is important to find the problem early.

Keep your workspace clean. Stay away from things like some rubbers and oils. These can cause cure inhibition.

Use barrier coatings to protect your molds. These coatings stop bad substances from blocking silicone curing.

Do a patch test with new materials. This helps you check if they work together before you start your silicone project.

Control the temperature and humidity in your workspace. This helps silicone cure the right way.

What Is Silicone Cure Inhibition?

Cure Inhibition Explained (Platinum vs Tin Silicone)

Silicone cure inhibition means your silicone does not harden or stays sticky after you mix and pour it. Sometimes, parts of your mold feel soft or slimy, even if you wait the right amount of time. This problem can waste your supplies and mess up your project.

Addition cure silicones stick to most surfaces when heated above 120⁰C. But, some things on the surface can stop the silicone from curing or even ruin it. This can make the silicone not cure at all or leave a sticky or slimy layer.

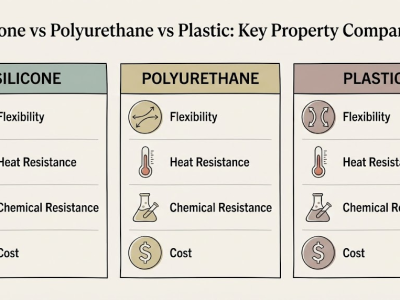

It is important to know the difference between platinum-cure and tin-cure silicones. These two types react in different ways to things that can cause problems. Platinum-cure silicones use platinum as a helper. Tin-cure silicones use tin. The table below shows how each type acts when cure inhibition happens:

Type of Silicone | Catalyst Used | Sensitivity to Contaminants | Cure Inhibition Characteristics |

|---|---|---|---|

Platinum-Cure Silicone | Platinum | Highly sensitive to sulfur | Will not cure in the presence of sulfur |

Tin-Cure Silicone | Tin | Less sensitive to sulfur | Can cure over sulfur if sealed properly |

Platinum-cure silicones are very sensitive to sulfur and will not cure if they touch it.

Tin-cure silicones can still cure over sulfur if you seal them the right way.

You should always check what kind of silicone you have before you start. This helps you stop cure inhibition and makes sure your silicone rubber hardens like it should.

Why Cure Inhibition Matters in Silicone Molding

Cure inhibition can cause a lot of trouble in molding. If your silicone does not cure, you waste time and money. Sticky or uncured silicone can hurt your mold and make it hard to take out your part. You want your material to be smooth, strong, and fully cured for the best results. When you know about silicone cure inhibition, you can stop problems and get good results every time you use silicone.

Quick Diagnosis – Is Your Silicone Experiencing Cure Inhibition? ⭐⭐⭐

You want your silicone project to work well. It is important to spot cure inhibition early. Cure inhibition can mess up your molding and waste your supplies. You can check for problems before you finish. Watch for signs that show your silicone is not curing right.

Here are the most common things you might see:

The silicone does not cure. It stays soft and never gets hard.

You notice a slimy or sticky layer on top.

The silicone looks runny, sticky, or gummy where it touches the mold.

If you see any of these signs, you probably have cure inhibition. Do not ignore these clues. They mean your silicone is touching something that stops it from curing. Sometimes, the problem only happens in some spots, especially where the silicone meets the mold.

Tip: Always check the surface and edges of your mold after curing. If you find sticky or slimy spots, you might have a cure inhibition problem.

You can do a simple touch test. Press your finger gently on the silicone after it cures. If it feels sticky or leaves stuff on your finger, it did not cure right. Cured silicone should feel smooth and firm.

You can also look for uneven curing. Some parts may get hard while others stay soft. This means something is stopping the silicone from curing. You should check your workspace, mold, and any release agents you used.

Quick diagnosis helps you save time and supplies. If you find cure inhibition early, you can fix the problem before starting again. You will get better results and feel less frustrated with your molding projects.

Common Causes of Silicone Cure Inhibition

Materials That Commonly Cause Cure Inhibition ⭐⭐⭐

Many things can stop silicone from curing. Some are things you use every day. If you work with silicone molds, you need to know what to avoid. Here are the top five materials that often cause cure inhibition:

Acrylonitrile butadiene rubber

Masking tapes

Polybutadiene rubber (BR)

Alkenes

Natural rubber

These materials can react with silicone and block curing. You should check your workspace and tools for these before you start. If you use any of them, your silicone might stay sticky or not cure.

Contaminants and Handling Issues

Contaminants can get into your project and cause cure inhibition. Oils from your hands, dust, or leftover cleaning products can stop silicone from curing. You should always wear gloves when you touch silicone. Clean your molds with the right products and let them dry. If you touch the mold with bare hands, you might leave oils that block curing. Even small bits of old cured material can cause problems if they stick to the mold. You need to keep your workspace clean and free from anything that could mess up the silicone.

Tip: Always use lint-free cloths and do not use household cleaners with sulfur or amines. These can cause cure inhibition and ruin your project.

Environmental and Process Factors

The air around you can change how silicone cures. Temperature and humidity are important for cure inhibition. If the air is too dry, curing slows down. If it is too humid, silicone may cure too fast and not set right. You should watch the temperature and humidity in your workspace. The table below shows how these things affect curing time:

Environmental Factor | Change | Effect on Curing Time |

|---|---|---|

Temperature | Increase from 19°C to 39°C | Curing time reduced by about half |

Humidity | Increase from 7.6% to 36.7% RH | Curing time reduced from about 11 hours to 4 hours |

Humidity levels change how fast silicone cures and how strong it gets. The crosslinking reaction needs water, so moisture in the air is important. Low humidity can make curing slow, while high humidity can make it too fast. You should control these things to avoid cure inhibition and get strong, fully cured silicone.

How to Prevent Cure Inhibition in Silicone Molding

Material Compatibility Testing (Patch Test Method)

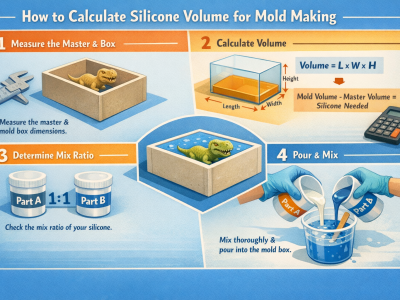

You can stop cure inhibition by testing your materials first. The patch test helps you see if your mold or coating will react with silicone. Put a little silicone on the surface you want to check. Wait for it to cure, then look for sticky or soft spots. This easy test saves you time and supplies. The table below shows how different products act during patch testing:

Product Name | Cure Inhibition |

|---|---|

Rustoleum smooth protective enamel | Yes |

Rustoleum flat gray primer | No |

Duplicolor filler primer (High build formula) | No |

Rustoleum acrylic lacquer (Crystal clear gloss) | No |

Tree House Studio clear acrylic matte coating | No |

ABS (control) | No |

If a product causes cure inhibition, do not use it with silicone molds.

Surface Sealing and Barrier Coatings

You can protect your mold by using barrier coatings. These coatings block things that cause cure inhibition. Always clean your surfaces before you use silicone. Some people add a barrier coat to keep silicone safe from things that stop curing. Do not let silicone touch harmful substances. This step helps you get strong, fully cured material every time.

Put a barrier coat on the mold.

Clean your mold before pouring silicone.

Keep silicone away from bad chemicals.

Cure inhibition often comes from photoinitiators in resin. You need to clean these off the surface to stop problems.

Proper Mold Preparation and Cleaning

You need to get your mold ready the right way to stop cure inhibition. Cleaning agents like isopropyl alcohol help remove uncured resin and dust. Wash your print with dish soap and water after using alcohol. Let the mold dry all the way before you pour silicone. Experts say to follow these steps for the best results:

Wash printed parts in two baths of isopropyl alcohol for ten minutes each.

Clean with soap and water to get rid of any resin left.

Cure underwater if needed, then dry the mold completely.

Always wear gloves when you touch silicone molds. This keeps oils and dirt off the surface. Clean molds help silicone cure well and stop sticky spots.

Solutions – How to Fix Cure Inhibition Problems

Cleaning and Surface Treatment Methods

You can fix cure inhibition by cleaning and treating your mold. First, control the moisture in your workspace. Find where water comes from and fix leaks. Use dehumidifiers to keep humidity under 50%. Take away any mold you see and clean the area around it. Put on mold-resistant coatings to stop mold from coming back. Heat treatment is also a good way to kill mold. You can use 140°F for 30 minutes or 160°F for 10 minutes. This kills most mold types. Steam at 212°F works right away. The table below shows steps for cleaning and stopping mold:

Phase | Description |

|---|---|

Moisture Control | Fix leaks, make air flow better, keep humidity under 50% |

Complete Treatment | Remove mold, clean around it, use extra treatments |

Prevention | Watch humidity, use mold-resistant coatings, plan regular checks |

Tip: Always clean your mold with isopropyl alcohol. Let it dry all the way before you pour silicone. This helps stop sticky or soft spots.

Using Barrier Coats or Sealers

Barrier coats or sealers help stop cure inhibition. If you use sulfur-based clays or tricky surfaces, put on a clear acrylic lacquer. This coat blocks chemicals that cause cure inhibition. Test a small spot first. If you see sticky or gummy silicone, add a barrier coat before you pour. This step keeps your project safe and helps the silicone cure right.

Put on a thin layer of clear acrylic lacquer.

Let it dry before you pour silicone.

Test a small spot to check if it works.

Switching to Tin-Cure Silicone (When Appropriate)

Sometimes, using tin-cure silicone fixes cure inhibition. If you use polyester surfaces or sanded molds, platinum-cure silicone may not work well. Tin-cure silicone works better for these jobs. You will not have sticky or uncured spots. Pick tin-cure silicone if you see cure inhibition from styrene or open surfaces. This change helps you get strong and good results for your molds.

Note: Always check your materials and surfaces before you pick your silicone. This helps you avoid sticky spots and wasting supplies.

Practical Tips and Recommended Products

Mold Release Agents and Barrier Coatings

You can stop cure inhibition by picking the right mold release agents and barrier coatings. These products help you make clean parts and keep your molds safe. Here are some good mold release agents for silicone projects:

A353 Endurance Mold Release: It works well for hard jobs and does not build up.

A635 Food Grade Silicone Lubricant: You can use it for food or medical molding.

E202 Dry Mist Silicone Mold Release: It gives a light, even coat for parts you want to paint or glue later.

E206 Silicone Mold Release: It works for many molds and is easy to use by hand or machine.

E236 Urethane Mold Release: This one is best for urethane and hard shapes. It helps you take out parts without breaking them.

You should always test a small spot first. This helps you stop cure inhibition and saves your materials.

Specialty Products for Cure Inhibition Prevention

Some products work better than others to stop silicone cure inhibition. Barrier coatings make a shield between your mold and the silicone. Clear acrylic sprays or special sealers can block chemicals that cause cure inhibition. You can use these on clay, resin, or 3D printed molds. Always let the coating dry before you pour silicone. This keeps your parts strong and smooth.

Tip: Use a barrier coat if you work with sulfur-based clays or surfaces you do not know. This helps you stop sticky or soft spots.

Application Techniques for Complex Molds

Complex molds need extra care to cover every spot. You do not want thin spots that can cause cure inhibition. Try these ways:

Crosshatch Pattern: Brush or spray left to right, then top to bottom. This covers all areas.

Dipping Techniques: Dip the mold straight down for even coverage. Pull it out slowly to stop runs or thick spots. Use a few thin dips instead of one thick dip.

These ways help you get a smooth, even layer. You lower the chance of cure inhibition and get better results with your silicone molding.

FAQ – Silicone Cure Inhibition ⭐⭐⭐

You might have questions about silicone cure inhibition. Many people who make molds ask the same things when they have trouble. Here are answers to the most asked questions:

What causes silicone cure inhibition?

Lots of things can stop silicone from curing. Some examples are certain rubbers, tapes, and chemicals. You can look at the table below to see common things that cause problems:

Substances that Cause Inhibition |

|---|

Acrylonitrile butadiene rubber |

Masking tapes |

Polybutadiene rubber (BR) |

Alkenes |

Natural rubber |

Amines |

Neoprene |

Polyisoprene (IR) |

Nitrile rubber (NBR) |

Sulphur |

Polyurethanes |

Organometallic compounds |

Paper tapes |

Solder flux residues |

Styrene butadiene rubber (SBR) |

Phosphate compounds |

Latex |

Phosphorus |

How can you prevent cure inhibition?

You can stop cure inhibition by using barrier coats and cleaning surfaces well. Always test new materials with a patch test before you pour silicone. Do not use latex gloves in your workspace. Keep addition-cured and polycondensation-cured silicones apart.

What are some common misconceptions?

You may think your mold is safe if it looks clean, but some things can still cause trouble.

Using latex gloves can mess up your silicone project.

Not all woods are safe for silicone. You need to seal wood before you use it.

Both tin-cure and platinum-cure silicones can have problems with some types of wood.

What should you do if you suspect cure inhibition?

Clean the surface again and put on a barrier coat.

Try a patch test on a small spot.

Switch to another silicone type if you still have trouble.

Tip: Always check your materials and workspace before you start. This helps you save time and supplies.

If you follow these steps, you can lower the chance of silicone cure inhibition and get better results with your molds.

Conclusion – Best Practices to Avoid Silicone Cure Inhibition

You want your silicone projects to work every time. You can follow easy steps to stop cure inhibition. This helps you get strong and smooth results. Pick the right silicone for your mold. Always check if your materials match. Try a patch test to see if your mold or coating causes trouble.

Clean your workspace before you start. Wear gloves to keep oils and dirt off your mold. Wash your molds with isopropyl alcohol. Let them dry all the way. If you use barrier coatings, let them dry before pouring silicone. You can use clear acrylic sprays or special sealers for extra safety.

Keep your workspace at the right temperature and humidity. You can use a table to watch your curing steps:

Step | Why It Matters |

|---|---|

Clean mold | Gets rid of contaminants |

Use barrier coat | Stops bad chemicals |

Control humidity | Helps silicone cure well |

Patch test | Checks if things work |

Tip: Always test new materials before big projects. This saves you time and supplies.

You can stop silicone cure inhibition by following these tips. You will have fewer sticky spots and better results. Remember, getting ready is important. You can fix most problems before they happen. Stay neat, use good products, and check your work often. Your silicone molds will cure well, and your projects will look great. 😊

You can stop silicone cure inhibition if you follow some easy steps. Clean your molds and your workspace before you begin. Try a patch test to see if your materials are safe. Use barrier coats if you need them. Watch the temperature and humidity when your silicone is curing.

Good preparation and using the right products help you get strong and smooth silicone molds. If you use these tips, your results will be good every time. 😊

LKprototype

LKprototype