Share a little biographical information to fill out your profile. This may be shown publicly.

Looking to understand molding polyurethane? This essential process transforms liquid polyurethane into durable, precision parts. We’ll explore different techniques like open cast, compression, and injection molding to help you find the best method for your needs, whether it’s for intricate designs or cost-effective production. Key Takeaways Polyurethane molding employs various techniques, including open cast, compression, and injection molding, to create precise parts suitable for diverse industries such as automotive and medical. Mold preparation is critical, involving sealing agents and releasing agents to ensure successful molding and avoid adhesion issues, with the technique chosen based on part complexity. Polyurethane’s physical properties,…

Vacuum casting is a process used to create precise prototypes and small-batch parts with silicone molds. It’s favored for its accuracy and speed, making it ideal for product development. This guide covers how vacuum casting works, the materials involved, and its benefits. Key Takeaways Vacuum casting is a precise manufacturing technique using silicone molds and vacuum environments to produce high-quality prototypes and small-batch parts. The process includes creating a master model, making silicone molds, mixing and pouring resins, and finishing the products, offering tolerances of ±0.1mm. Vacuum casting is cost-effective for low-volume production compared to injection molding and delivers superior…

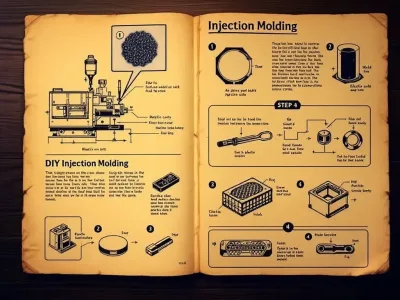

If you’re looking to learn how to make an injection mold, understanding the steps is crucial. The process includes designing the mold, prototyping, machining, and assembling. This guide will walk you through each stage, helping you create a functional injection mold. Key Takeaways Injection molding is a crucial manufacturing technique that involves injecting molten plastic into metal molds to produce high-quality parts efficiently. Key factors in mold design include the choice of materials, cooling channel optimization, and detailed design features such as draft angles and parting lines, all of which ensure product quality and production efficiency. Proper maintenance and care…

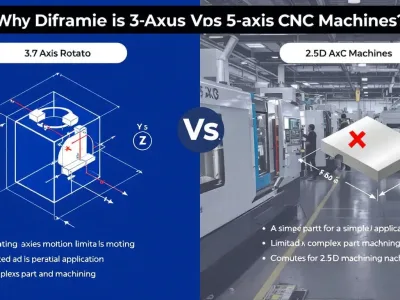

Choosing between a 3 Axis CNC and a 5 Axis CNC machine depends on your project’s complexity and precision needs. In this article, we will explore the key differences, benefits, and drawbacks of 3 axis CNC vs 5 axis machines to help you decide which is right for you. Key Takeaways 3-axis CNC machines are cost-effective and suitable for simpler tasks, but they struggle with complex geometries and require multiple setups for intricate designs. 5-axis CNC machines excel in precision and efficiency, capable of machining complex shapes with fewer setups, making them ideal for industries demanding high accuracy like aerospace…

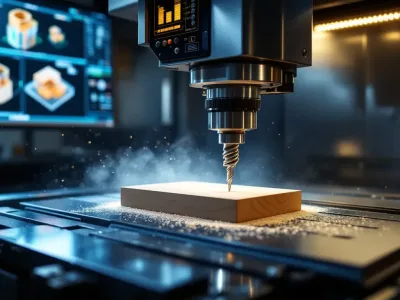

Looking to cut down costs on your CNC machining projects while maintaining top-notch quality? Low cost CNC machining is achievable with practical strategies like optimizing material selection, simplifying part designs, and leveraging online CNC services. This article dives into proven methods to help you get the best value for your investment without compromising on precision or quality. Key Takeaways CNC machining combines precision and versatility, making it essential in industries like aerospace and automotive, while online platforms offer cost-effective access to these services. Costs in CNC machining are influenced by material selection, design complexity, and machine setup efficiency, with strategies…

Looking for the top CNC equipment manufacturers? This article covers the leading companies, their specialties, and why they stand out in the industry. Key Takeaways CNC machines enhance precision and efficiency in manufacturing by automating processes and executing tasks directly from CAD files. Leading CNC equipment manufacturers such as Yamazaki Mazak, Trumpf, and DMG MORI are recognized for their innovative technologies and quality machinery, catering to various industries. Automation in CNC machining, including robotic systems and automated tool changers, significantly improves productivity and reduces manual labor, though challenges like initial investment remain. Understanding CNC Equipment A CNC machine is a…

A 4 axis CNC machine adds a rotational axis to the traditional three axes, allowing for more complex and precise machining. This additional axis enables the machine to access the workpiece from different angles, making it ideal for intricate designs and complex geometries. In this article, you’ll learn about the features, uses, and benefits of 4 axis CNC machines, helping you understand why they could be a valuable addition to your manufacturing process. Key Takeaways 4-axis CNC machining offers enhanced precision and design flexibility by introducing an A-axis for rotational movement, crucial for complex components in industries such as aerospace…

Need to quickly convert your CAD designs into physical models? Rapid prototyping services offer a fast and reliable way to create prototypes for testing and validation. This article dives into the different technologies available, the materials you can use, and how these services can accelerate your product development. Key Takeaways Rapid prototyping is essential for quickly producing functional prototypes from CAD models, enabling early design testing and iterations. Key technologies in rapid prototyping, such as CNC machining, 3D printing, and injection molding, provide flexibility and efficiency for both low and high-volume productions. Selecting appropriate materials is crucial for prototype characteristics,…

G-code is the primary language CNC machines use to execute precise tasks, commonly referred to as g code in CNC. This article explains what G-code is, how it functions in CNC machining, and the essential commands you need to know. Key Takeaways G-code is a crucial programming language for CNC machines, automating tasks that enhance precision and repeatability in manufacturing. Understanding key G-code commands, such as G00 for rapid movement and G01 for linear interpolation, is essential for optimizing machining processes. Differentiating between modal and non-modal G-codes, as well as utilizing advanced techniques like canned cycles, significantly improves CNC programming…

Facing a choice between alloy steel vs stainless steel? Understanding their differences in strength, corrosion resistance, cost, and applications will help you decide the best material for your project. Key Takeaways Alloy steel is versatile and primarily used for high strength and toughness applications, while stainless steel is known for its superior corrosion resistance and aesthetic appeal. The choice between alloy steel and stainless steel depends on factors like mechanical properties required, environmental conditions, and long-term cost considerations, with alloy steel being generally less expensive upfront but potentially requiring more maintenance. Understanding the specific applications of each type of steel—such…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.